齐荣荣1,2,宁正福1,2,张 爽1,2,黄 亮1,2,陈志礼1,2

(1.中国石油大学(北京) 石油工程教育部重点实验室,北京 102249; 2.中国石油大学(北京) 油气资源与探测国家重点实验室,北京 102249)

摘 要:基于体积法建立页岩气含气量预测模型,含气量包括吸附气量和游离气量,在计算吸附气量时考虑了页岩矿物组成、温度、压力、水分和非甲烷多组分气体,在计算游离气量时考虑了吸附相体积,最终采用涪陵焦石坝地区焦页1井页岩现场解吸数据验证模型。结果表明,当考虑吸附相体积时,含气量模型计算值与现场解吸数据较吻合,当不考虑吸附相体积时,页岩含气量被高估27%~38%;水分对页岩含气量的影响较小;多组分气体不仅改变页岩含气量,也改变页岩气的赋存状态,不考虑多组分气体将高估目标区域含气量5.6%~31.8%。所建含气量模型精确性依赖于室内岩芯实验结果,未来应进一步开展含水页岩对多组分气体吸附实验研究,准确计算页岩气含气量。

关键词:页岩气含气量;水分;多组分气体;吸附相体积;预测模型

中图分类号:P618.13

文献标志码:A

文章编号:0253-9993(2018)09-2553-09

移动阅读

齐荣荣,宁正福,张爽,等.考虑含水和多组分气体的页岩气含气量预测模型[J].煤炭学报,2018,43(9):2553-2561.doi:10.13225/j.cnki.jccs.2017.1837

QI Rongrong,NING Zhengfu,ZHANG Shuang,et al.Prediction model of shale gas content with the consideration of moisture and multicomponent gas[J].Journal of China Coal Society,2018,43(9):2553-2561.doi:10.13225/j.cnki.jccs.2017.1837

收稿日期:2017-12-27

修回日期:2018-04-04

责任编辑:韩晋平

基金项目:国家自然科学基金资助项目(51774298)

作者简介:齐荣荣(1990—),女,湖北随州人,博士研究生。Tel:010-89732318,E-mail:qrr_cup@163.com

QI Rongrong1,2,NING Zhengfu1,2,ZHANG Shuang1,2,HUANG Liang1,2,CHEN Zhili1,2

(1.MOE Key Laboratory of Petroleum Engineering,China University of Petroleum(Beijing),Beijing 102249,China; 2.State Key Laboratory of Petroleum Resources and Prospecting,China University of Petroleum(Beijing),Beijing 102249,China)

Abstract:A prediction model of shale gas content was established based on the volumetric method.The total gas content of shale includes gas in the adsorbed phase and free phase.The amount of gas in the adsorbed phase was calculated with the consideration of mineral composition of shale,temperature,pressure,moisture and non-methane gas,and in the calculation of gas amount in the free phase the adsorbed phase volume was con-sidered.The model validation was conducted with the experimental data of in-situ desorption of JY-1 well in Fuling Jiaoshiba area.The results show that when the adsorbed phase volume is considered,the gas content calculated by the model is in good agreement with the field desorption data.However,when the adsorbed phase volume is not considered,the gas content is overestimated by 27%-38%.Moisture has little effect on the gas content of shale.Multicomponent gas not only changes the gas content of shale,but also changes the occurrence state of shale gas.The gas content will be overestimated by 5.6%-31.8% without the consideration of multicomponent gas.The accuracy of the model greatly depends on the results of indoor experiments.To obtain an accurate shale gas content,a further study of adsorption experiments of multicomponent gas on moisture-equilibrated shale should be carried out in the future study.

Key words:gas content of shale gas;moisture;multicomponent gas;adsorbed phase volume;prediction model

页岩气是指赋存于暗色泥页岩及其所夹砂岩、粉砂岩地层中的天然气,属于一种自生自储的非常规气藏,其存储方式包括游离态、吸附态和溶解态[1]。其中,游离态气体是以游离方式储集在有机质孔隙、黏土孔隙、碎屑孔隙及天然裂缝中;吸附态气体是指吸附于有机质、黏土基质表面的天然气;溶解态气体是指溶解于地层水和液态烃中的天然气,一般含量较少可忽略不计[1-4]。

页岩气含气量是指每吨页岩中所含天然气折算到标准压力和温度(101 325 Pa,25 ℃)条件下天然气总量,为游离态、吸附态和溶解态气体之和[5]。目前常用直接法和间接法来测定和计算页岩含气量。直接法即为现场解吸法,该方法测定的的含气量由3部分组成,即损失气量、解吸气量和残余气量。其中损失气量是指岩样快速取出,现场直接装入解吸罐之前释放出的气量;解吸气量指岩样装入解吸罐之后解吸出的气体总量;残余气量是指终止解吸后仍留在页岩中的那部分气体[6]。现场解吸法测定含气量最能体现储层真实含气量,但该方法只能对有限的岩心进行测定,且解吸耗时长,成本高[5,7-8]。间接法一般通过室内岩芯等温吸附实验得到吸附气含量,通过测井解释方法得到孔隙度和含气饱和度等参数,进而根据体积法计算游离气含量,吸附气和游离气含量之和即为页岩总的含气量[7,9-10]。由于页岩吸附能力受温度、压力、有机碳含量、水分含量等众多因素影响,前人在建立吸附气计算模型时存在一定问题:① Langmuir体积和压力多采用单个温度下的吸附数据拟合得到,未考虑地层条件下温度和压力的变化对吸附的影响;② 多采用干燥页岩样品吸附量代表页岩实际吸附量,而页岩气在地层中处于含水环境下[11-12];③ 采用甲烷纯组分气体吸附量代表页岩气吸附量,实际上,页岩气储层中除含有CH4气体以外,还有其他烃类气体以及CO2和N2等非烃类气体,AMBROSE等的研究表明,当在计算页岩气含气量的过程中考虑多组分气体时,最终含气量相比于甲烷纯组分气体变化不大,但是会影响气体在储层中的赋存方式,即会改变吸附气和游离气含量的相对大小[15]。前人在计算游离气含量时,认为游离气占据整个孔隙空间,而实际上页岩有机质中含有大量纳米级孔隙[16-18],吸附气体在这样的孔隙中占有较大比例,直接采用孔隙体积计算可能会高估游离气含量[19]。为此笔者建立了一个页岩气含气量计算模型,该模型在计算吸附气含量时考虑温度、压力、水分含量和非甲烷气体影响,在计算游离气含量时考虑吸附相体积,分别对吸附态和游离态页岩气含量进行了预测。

采用页岩气储集体体积模型来计算页岩气含气量。页岩气储集体包括岩石骨架和孔隙流体两部分,其中岩石骨架由有机质、黏土矿物、附着在黏土矿物上的束缚水以及石英、长石等脆性矿物组成,孔隙流体包括吸附气、游离气、溶解气、原油和自由水[20]。由于溶解在原油和自由水中的气体量很小,在计算含气量时可忽略不计[15,19]。页岩气含气量表达式为

Gst=Ga+Gf

(1)

式中,Gst,Ga和Gf分别为页岩气总的含气量、吸附气量和游离气量,m3/t。

页岩气一般吸附在页岩有机质和黏土矿物表面,其影响因素包括页岩本身性质,如有机质类型、含量和成熟度,黏土矿物类型和含量,孔隙结构,水分含量以及外部环境条件,如温度和压力[13,21-27]。一般采用Langmuir方程及其修订形式模拟页岩气吸附[23,28],吸附气量表达式为

Ga=22.4na=22.![]()

(2)

式中,na为气体吸附量,mmol/g;nL为Langmuir吸附量,为岩石表面覆盖满一层吸附气体时所对应的最大吸附量,mmol/g;p为地层压力,MPa;pL为Langmuir压力,为Langmuir吸附量的一半所对应的压力,MPa。

假设Langmuir吸附量nL为一个与温度无关的常数,其大小仅与气体可接触到的表面积有关[29]。研究表明,页岩吸附量与有机质含量成正比[13-14,22],黏土矿物含量对页岩吸附量也具有一定贡献[29]。页岩吸附量可表示为这些组分(有机和无机组分)吸附量的线性加和[23],即

(3)

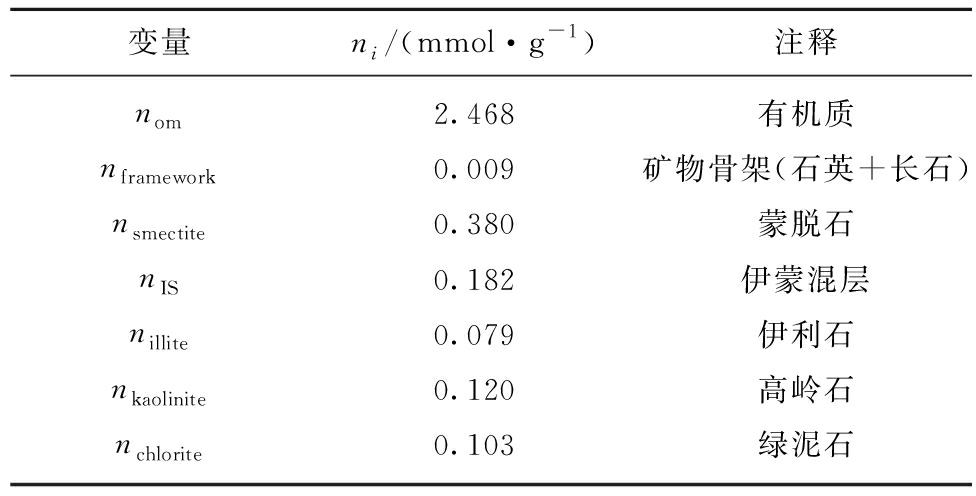

其中,ni为页岩组分i的Langmuir吸附量,mmol/g;wi为页岩组分i的质量分数,无量纲。页岩不同组分的Langmuir吸附量见表1。

Langmuir压力是温度的函数,其自然对数与温度的倒数之间有较好的线性关系[14,23,28]:

(4)

其中,A=ΔH/R,B=-ΔS0/R+ln p0;ΔH为吸附焓,在数值上等于等量吸附热的负数,J/mol;ΔS0为摩尔吸附熵,J/(mol·K);p0为理想状态下的压力,取0.1 MPa;R为气体常数,为8.314 J/(mol·K)。绘制不同温度条件下ln pL与1/T之间关系曲线,那么曲线斜率即为A,截距即为B。

表1 页岩有机和无机质Langmuir吸附量[29]

Table 1 Langmuir adsorption amount of organic and inorganic matter of shale[29]

当不考虑吸附相体积时,游离气量表达式为

(5)

当考虑吸附相体积时,部分孔隙空间被吸附相气体占据,则有

(6)

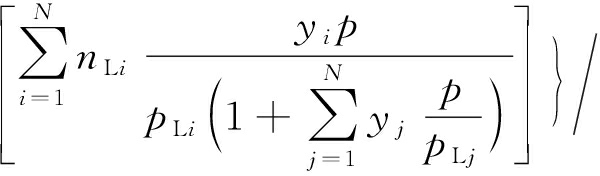

其中,φa为吸附相孔隙度,在数值上等于吸附相体积Va(cm3/g)与岩石总体积Vb(cm3/g)之比:

(7)

式中,Vfree为游离气体积,cm3/g;Bg为气体体积系数,无量纲;φ为孔隙度,无量纲;Sw为含水饱和度,无量纲;ρb为岩石密度,g/cm3;M为气体摩尔质量,g/mol;ρa为气体吸附相密度,g/cm3。

气体体积系数通过单位气体体积在地层条件下体积Vg(cm3/g)与在地面标准状态(20 ℃,101 325 Pa)下体积Vsc(cm3/g)之比求得

.456×![]()

(8)

式中,ρg为气体在地层温度和压力条件下的密度,g/cm3,对于甲烷气体,采用Setzmann状态方程[30]计算得出;对于混合气体,通过混合气体GERG状态方程求得[31]。

页岩储层中普遍存在水分,水分多以内在水分存在于页岩基质和以自由水形态存在于裂缝中。水分对页岩含气性的影响是双重的,一是影响气体流动和渗透率,二是堵塞孔隙喉道减少气体吸附量。本小节仅考虑水分对页岩气吸附的影响。

前人在建立气体吸附量与水分含量之间经验方程做过诸多尝试。在早期研究中,ETTINGER等[32]提出气体吸附量与水分含量之间存在线性关系:

(9)

其中,na,moist和na,dry分别为气体在含水和干燥页岩上的吸附量,mmol/g;m为水分质量分数;A为水分影响系数,无量纲。

CROSDALE等[33]在后来的研究中发现气体吸附量与水分含量之间并非线性关系,而是符合幂函数的非线性关系:

na,moist=cmd

(10)

其中,c和d为常数,无量纲,通过实验数据拟合得到。幂函数方程可以较好地拟合水分含量较高的实验样品,但是无法拟合水分含量接近0的实验样品。这是由于当水分含量接近0时,由幂函数求得的吸附量可能是一个无穷值。

方程(9)和(10)各自存在局限性,近年来,CHEN等[34]克服以上两个方程的局限性,采用指数方程来表征气体吸附量与水分含量之间关系:

na,moist=na,dryexp(-λm) (0≤m≤mc)

(11)

其中,mc为平衡水分含量,质量百分数;λ为吸附量衰减指数,无量纲,通过实验数据拟合得到。该指数方程只适用于单个压力下含水页岩吸附量与水分含量之间转换,在实际应用中具有局限性,为此,CHEN等[34]通过Langmuir方程,将指数方程进一步扩展,得到不同压力条件下含水页岩吸附量与水分含量之间关系式:

(-λm) (0≤m≤mc)

(12)

以上各式中,水分含量m为指页岩孔隙中所含水分的质量mw(g)与干燥页岩质量mb(g)比值:

×![]() ×100

×100

(13)

含水饱和度Sw为指页岩孔隙体积中水的体积 Vw(cm3/g)与页岩孔隙体积Vvoid(cm3/g)的比值:

(14)

结合方程(13)和(14)可得

×100

(15)

式中,ρw为水的密度,取1 g/cm3。

那么,考虑含水的页岩含气量预测模型则可表示为

Gst,moist=[φ![]() ×

×

![]() ρbBg)+

ρbBg)+

22.![]()

(16)

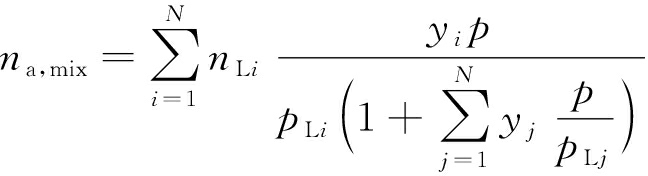

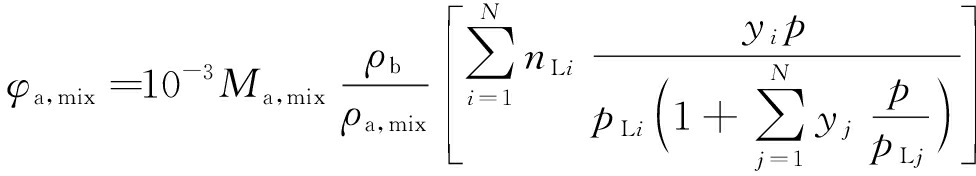

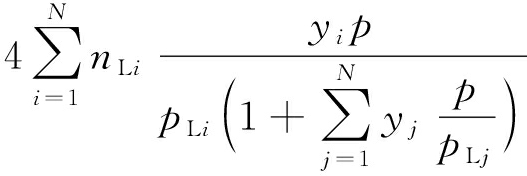

页岩气储层中除含有CH4气体以外,还有其他烃类气体以及CO2和N2等非烃类气体。这些非CH4组分的体积分数虽然不大,但它们会对页岩气的赋存状态产生一定影响[15]。笔者采用扩展的Langmuir(EL)方程计算混合气体吸附量:

(17)

(18)

则考虑多组分气体的页岩气含气量预测模型为

Gst,mix={φ![]()

(ρbBg,mix)+22.

(19)

其中,nLi为气体组分i的Langmuir吸附量,mmol/g;pLi为气体组分i的Langmuir压力,MPa;Bg,mix为混合气体体积系数,无量纲;yi为气体组分i在游离相中的摩尔分数,一般通过气相色谱仪检测现场解吸数据得到;N为气体组分数;Ma,mix为吸附相中混合气体平均摩尔质量,g/mol;ρa,mix为混合气体吸附相密度,g/cm3。Ma,mix和ρa,mix均可通过纯组分气体参数在Kay混合规则下计算得到[15]:

(20)

![]() ρixi

ρixi

(21)

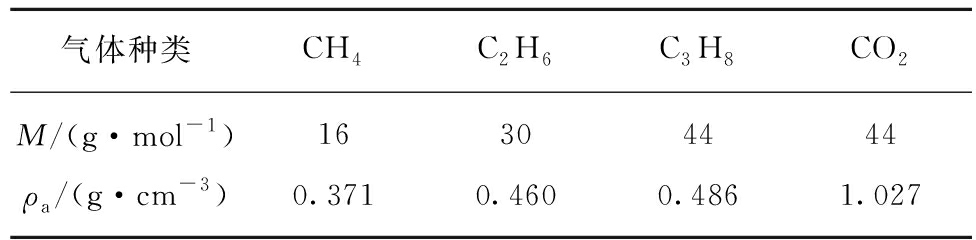

其中,xi为混合气体中组分i在吸附相中的摩尔分数,通过游离相中气体组成和EL方程计算得到;Mi为混合气体中组分i的摩尔质量,g/mol;ρi为混合气体中组分i的吸附相密度,g/cm3。纯组分气体吸附相密度通过范德华状态方程计算得出[15]。表2列出了纯组分气体的摩尔质量和吸附相密度。

表2 纯组分气体摩尔质量与吸附相密度

Table 2 Molar mass and adsorbed phase density of pure component gas

采用涪陵焦石坝地区焦页1井页岩储层基础数据计算页岩吸附气量、游离气量和总的含气量,并将计算结果与现场解吸数据对比以验证模型的适用性。

涪陵页岩气田位于四川盆地川东南构造区川东高陡褶皱带万县复向斜包鸾—焦石坝背斜带中的焦石坝背斜,构造呈北东向展布[35],发育有大套的深灰色、灰黑色页岩、碳质泥页岩,属深水陆棚相沉积[36]。该区有机质类型主要为腐泥型干酪根,有机质丰度高(TOC含量为2.54%),热演化程度适中(镜质组反射率Ro为2.5%)[37],矿物组成为硅质、长石、方解石、白云石、黄铁矿和黏土,其中黏土矿物主要为伊利石、伊蒙混层和绿泥石[9]。孔隙类型可分为有机质孔隙、黏土矿物晶间孔、黏土矿物粒间孔和黏土矿物粒内孔[38],孔喉半径多小于50 nm,主要分布在4~16 nm内,对渗透率贡献较大的孔喉半径为6~25 nm[39]。

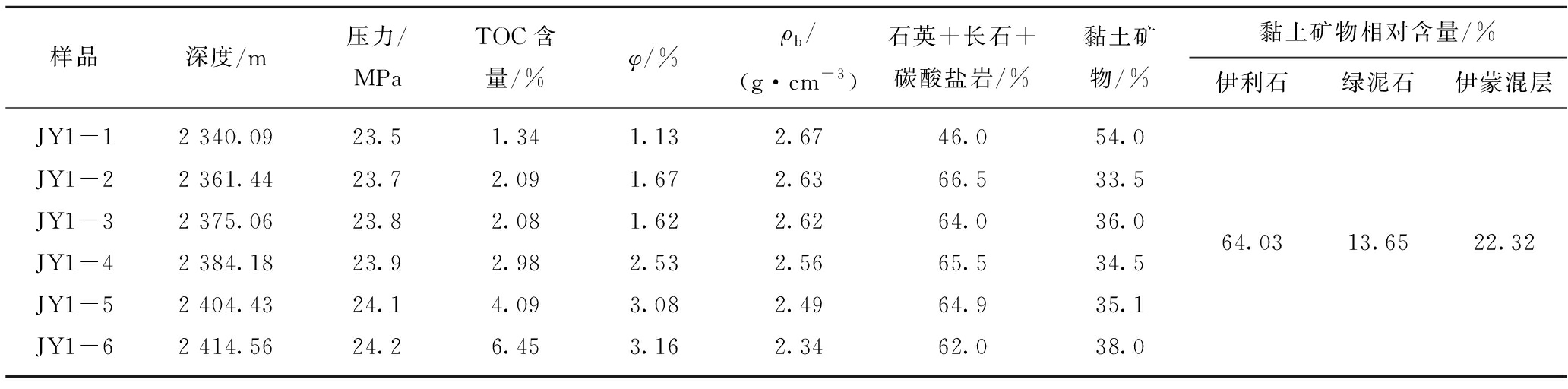

已知涪陵地区年平均地表温度为288.15 K,地温梯度为2.83 K/(100 m)[5],假设地面压力为0.1 MPa,地层压力梯度为1 MPa/(100 m),则根据地层深度可大致推断页岩储层温度和压力。表3为焦页1井不同深度页岩样品有机碳含量(TOC含量)[40]、矿物组成[40]、孔隙度[40]以及黏土矿物组成[41]。涪陵地区岩石密度通过郭旭升等的经验方程求出[42]:

ρb=-0.065TOC+2.757,R2=0.819

(22)

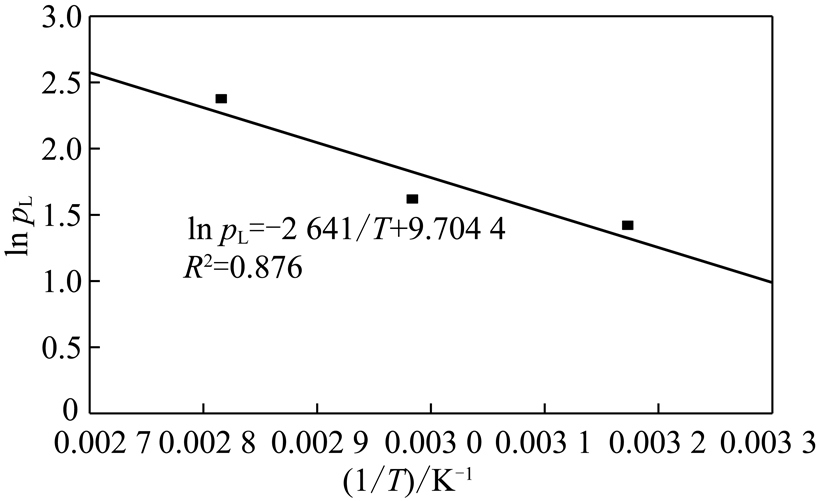

刘雄辉等针对涪陵焦石坝地区页岩开展了42,62,82 ℃条件下等温吸附实验[41]。为确定不同温度下Langmuir压力,采用Langmuir方程对实验数据进行拟合,得到3个温度下的Langmuir压力分别为4.14,5.05,10.77 MPa[41]。绘制ln pL与1/T之间关系曲线,如图1所示,可知斜率A=-2 641,截距B=9.704 4(R2=0.876)。

表3 涪陵焦石坝地区页岩矿物组成及物性特征[40-41]

Table 3 Mineral composition and physical characteristics of shale in Fuling Jiaoshiba area[40-41]

图1 Langmuir压力自然对数与温度倒数之间线性关系曲线

Fig.1 Linear relationship between the natural logarithm of Langmuir pressure and the reciprocal of temperature

陈乐求等针对焦石坝地区龙马溪组页岩开展了不同水分含量下的等温吸附测试[43],运用这些吸附数据,通过方程(11)拟合不同压力下含水样品与水分含量之间关系,拟合结果如图2所示,可知λ=0.186。由于目标样品在储层中所处压力环境相差不多,不同压力下含水页岩吸附量与水分含量之间关系曲线几乎重合,因此采用第1个压力(23.5 MPa)下含水页岩吸附量与水分含量之间拟合参数进行下一步运算。

图2 含水页岩吸附量与水分含量之间关系曲线

Fig.2 Relationship between the adsorption capacity of moisture-equilibrated shale and water content

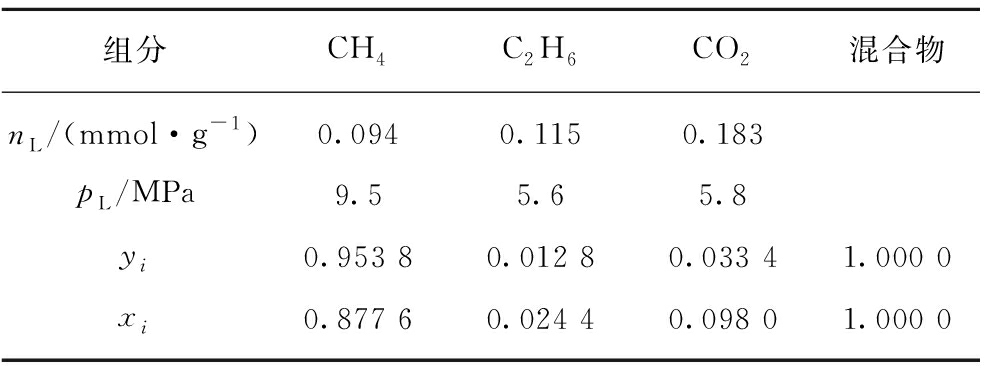

韩辉等以四川盆地东北部下寒武统海相页岩岩芯为研究对象,通过气相色谱仪对现场解吸气体进行了组分分析,结果表明,解吸气中含有CH4, C2H6,CO2和N2,这些气体的体积分数分别为95.38%~98.80%,0.43%~1.28%,0.25%~0.79%和0~3.49%,C3H8和C6+含量极低[44]。由于N2含量较小,且N2吸附量远小于CH4[45],因此在计算多组分吸附量时忽略N2。基于以上分析,涪陵焦石坝地区页岩气游离相组成见表4。为求得该地区页岩气吸附相组成,需用到页岩气混合气体中各组分的Langmuir参数(Langmuir吸附量和压力)。然而,据笔者所知,C2H6和CO2气体在焦石坝地区页岩上的吸附数据尚未公开发表,故笔者采用北美地区页岩的吸附数据[15],见表4。基于页岩气在游离相中组成、页岩气中各组分的Langmuir参数以及EL方程,便可求得页岩气在吸附相中组成(表4)。

表4 涪陵焦石坝地区页岩气吸附参数及组成

Table 4 Adsorption parameters and composition of shale gas in Fuling Jiaoshiba area

根据第1小节的讨论以及2.1节的基础数据,分别计算出了焦页1井不同地层深度下页岩吸附气量、游离气量和总的含气量,计算结果见表5和图3。由表5和图3可知,在目标地层深度范围内,总的含气量介于1.54~5.35 m3/t,吸附气量介于1.43~3.25 m3/t,游离气量介于0.01~2.10 m3/t;随地层深度的增加,吸附气量、游离气量和含气量均呈现逐渐增加的趋势。

焦页1井五峰组—龙马溪组取芯段(井深2 339.33~2 414.90 m)现场解吸实验结果表明,取芯段总含气量介于0.44~5.19 m3/t,平均为1.97 m3/t,主要以损失气和解吸气为主,残余气含量极低[46]。由图3(c)可知,页岩含气量预测值与现场解吸数据变化趋势一致,但在数值上前者大于后者。事实上,吸附气量是通过Langmuir方程计算的理论最大值,通过该吸附气量计算得到的含气量亦为最大值,而在现场解吸实验中,页岩岩芯从地层中被取出的过程中会损失一部分气体,加之存在解吸滞后,少量气体最终无法从岩芯中解吸出来而成为残余气,这些均将导致现场解吸含气量小于理论计算值。

表5 不同地层深度下,不同含气量模型预测结果

Table 5 Prediction results of different gas content models under different depth of formation

注:Ga,Gf,Gst单位均为m3/t。

图3 焦页1井吸附气量、游离气量与总含气量预测值与现场解吸数据对比(现场解吸数据来自文献[40])

Fig.3 Comparison of the predicted value of adsorbed gas,free gas and total gas content to the in situ desorption data of JY-1 well(in situ desorption data from literature[40])

由表5可知,当不考虑吸附相体积时,吸附气量不变,游离气量被高估,总的含气量被高估27%~38%。郭旭升等的研究表明,焦石坝地区龙马溪组页岩孔隙形态以两端开口的圆筒状及四边开放的平行板状孔等开放性孔为主,孔径大小主要分布在2~30 nm,以中孔为主,微孔次之,大孔含量较少[47]。因此在这些含有大量纳米级孔隙的页岩基质中,吸附相体积不可忽略,在计算页岩游离气含量时,应考虑吸附相气体占据体积。

当不考虑含水对页岩气含气量的影响时,吸附气量被高估2.01%~6.70%,总的含气量被高估1.17%~3.12%,很明显,这个高估的数值偏小。这可能与室内实验无法正确恢复储层含水条件以及实验数据误差有关。页岩中水分同煤中水分一样,大致可划分为3类,即自由水、吸收水和结晶水[48]。目前在讨论水分对页岩吸附的影响时,广泛采用不同饱和盐溶液处理页岩样品,得到不同水分含量的平衡水样品,进而在平衡水样品上开展等温吸附实验,得到含水样品吸附量。然而,平衡水过程仅仅恢复了吸收水和结晶水,不能恢复自由水[48],自由水对页岩吸附气含量的影响尚不可知。因此,在水分对页岩吸附影响的后续研究中,如何恢复储层条件下页岩含水是首先要解决的问题。另外,由于涪陵焦石坝地区含水页岩等温吸附实验数据缺乏,研究不具系统性,平衡水样品吸附量与水分含量之间数学关系还有待进一步验证和完善,笔者仅提供一种将室内实验研究和现场实际结合运用的思路和方法。

由图3可知,多组分气体不仅影响页岩总的含气量,也影响页岩气的赋存方式,即在吸附相和游离相中的含量。这可能是由于混合气体中各个组分的吸附能力不一样,随压力变化,各个气体组分在吸附相和游离相中的含量发生变化,即发生了组分分馏效应。当不考虑多组分气体时,随地层深度增加,页岩气吸附气量呈现先被低估而后被高估的趋势(图3(a)),游离气量则呈现相反的趋势(图3(b))。在2 340.09~2 375.06 m的地层深度范围内,多组分气体几乎对含气量无影响,而在2 384.18~2 414.56 m的地层深度范围内,不考虑多组分气体将会高估含气量5.6%~31.8%(图3(c),表5)。

(1)模型计算含气量大于现场解吸数据,这可能是由于模型计算吸附气量是通过Langmuir方程计算的理论最大值,通过该吸附气量计算得到的含气量亦为最大值,另外,现场解吸实验中,页岩岩芯从地层中被取出的过程中会损失一部分气体,加之存在解吸滞后,少量气体最终无法从岩芯中解吸出来而成为残余气,这些均将导致现场解吸含气量小于理论计算值。

(2)页岩中含有大量纳米级孔隙,由吸附气体组成的吸附相在页岩孔隙中占据的空间不可忽略,当不考虑吸附相体积时,页岩含气量被高估27%~38%。

(3)页岩考虑含水后总的含气量减少1.17%~3.12%,减小的幅度偏小,这可能与室内实验无法正确恢复储层含水以及研究区域实验数据稀少导致计算误差所致。

(4)多组分气体不仅影响页岩气的赋存状态,即页岩气在吸附相和游离相中的分布,也影响页岩气总的含气量。在2 384.18~2 414.56 m的地层深度范围内,不考虑多组分气体将会高估含气量5.6%~31.8%。

参考文献(References) :

[1] 石文睿,张超谟,张占松,等.涪陵页岩气田焦石坝页岩气储层含气量测井评价[J].测井技术,2015,39(3):357-362.

SHI Wenrui,ZHANG Chaomo,ZHANG Zhansong,et al.Log evaluation of gas content from Jiaoshiba shale gas reservoir in Fuling gas field[J].Well Logging Technology,2015,39(3):357-362.

[2] CURTIS J B.Fractured shale-gas systems[J].AAPG Bulletin,2002,86(11):1921-1938.

[3] JARVIE D M,HILL R J,RUBLE T E,et al.Unconventional shale-gas systems:The mississippian barnett shale of north-central Texas as one model for thermogenic shale-gas assessment[J].AAPG Bulletin,2007,91(4):475-499.

[4] PAN L,XIAO X,TIAN H,et al.Geological models of gas in place of the Longmaxi shale in Southeast Chongqing,South China[J].Marine & Petroleum Geology,2016,73:433-444.

[5] 张晓明,石万忠,舒志国,等.涪陵地区页岩含气量计算模型及应用[J].地球科学-中国地质大学学报,2017,42(7):1157-1168.

ZHANG Xiaoming,SHI Wanzhong,SHU Zhiguo,et al.Calculation model of shale gas content and its application in Fuling area[J].Earth Science-Journal of China University of Geosciences,2017,42(7):1157-1168.

[6] 尹腾宇.页岩含气性实验测试研究[D].北京:中国地质大学(北京),2012.

YIN Tengyu.Experimental research of shale gas bearing[D].Beijing:China University of Geosciences(Beijing),2012.

[7] 陈亚琳.涪陵页岩气田焦石坝地区含气量定量预测技术[J].海洋地质前沿,2017,33(1):53-61.

CHEN Yalin.Quantitative prediction technique for gas content and its application to Jiaoshiba area of Fuling shale gasfield[J].Marine Geology Frontiers,2017,33(1):53-61.

[8] SHTEPANI E,NOLL L A,ELROD L W,et al.A new regression-based method for accurate measurement of coal and shale gas content[J].SPE Reservoir Evaluation & Engineering,2010,13(2):359-364.

[9] 彭超,唐军,冯爱国,等.涪陵页岩气储层含气性测井评价[J].科学技术与工程,2017,17(2):190-196.

PENG Chao,TANG Jun,FENG Aiguo,et al.Gas content ability evaluation by logging technology in Fuling shale gas reservoir[J].Science Technology and Engineering,2017,17(2):190-196.

[10] 赵金洲,沈骋,任岚,等.页岩储层不同赋存状态气体含气量定量预测——以四川盆地焦石坝页岩气田为例[J].天然气工业,2017,37(4):27-33.

ZHAO Jinzhou,SHEN Cheng,REN Lan,et al.Quantitative prediction of gas contents in different occurrence states of shale reservoirs:A case study of the Jiaoshiba shale gasfield in the Sichuan Basin[J].Natural Gas Industry,2017,37(4):27-33.

[11] 李相方,蒲云超,孙长宇,等.煤层气与页岩气吸附/解吸的理论再认识[J].石油学报,2014,35(6):1113-1129.

LI Xiangfang,PU Yunchao,SUN Changyu,et al.Recognition of absorption/desorption theory in coalbed methane reservoir and shale gas reservoir[J].Acta Petrolei Sinica,2014,35(6):1113-1129.

[12] 李靖,李相方,王香增,等.页岩黏土孔隙含水饱和度分布及其对甲烷吸附的影响[J].力学学报,2016,48(5):1217-1228.

LI Jing,LI Xiangfang,WANG Xiangzeng,et al.Effect of water distribution on methane adsorption capacity in shale clay[J].Acta Mechanica Sinica,2016,48(5):1217-1228.

[13] ROSS D J K,BUSTIN R M.The importance of shale composition and pore structure upon gas storage potential of shale gas reservoirs[J].Marine & Petroleum Geology,2009,26(6):916-927.

[14] GASPARIK M,BERTIER P,GENSTERBLUM Y,et al.Geological controls on the methane storage capacity in organic-rich shales[J].International Journal of Coal Geology,2014,123(2):34-51.

[15] AMBROSE R,HARTMAN R C,AKKUTLU I Y.Multicomponent sorbed phase considerations for Shale Gas-in-place Calculations[J].SPE Production & Operations Symposium,2011,17(1):219-229.

[16] YANG W,ZHU Y,CHEN S,et al.Characteristics of the nanoscale pore structure in northwestern hunan shale gas reservoirs using field emission scanning electron microscopy,high-pressure mercury intrusion,and gas adsorption[J].Energy Fuels,2014,28(2):945-955.

[17] YANG F,NING Z,WANG Q,et al.Pore structure characteristics of lower Silurian shales in the southern Sichuan Basin,China:Insights to pore development and gas storage mechanism[J].International Journal of Coal Geology,2016,156:12-24.

[18] ZHAO J,XU H,TANG D,et al.A comparative evaluation of coal specific surface area by CO2 and N2 adsorption and its influence on CH4 adsorption capacity at different pore sizes[J].Fuel,2016,183:420-431.

[19] AMBROSE R J,HARTMAN R C,CAMPOS M D,et al.New pore-scale considerations for shale gas in place calculations[J].Society of Petroleum Engineers,2010:219-229.

[20] 耿龙祥,曹玉珊.页岩气资源/储量计算与评价技术规范解读[J].非常规油气,2015,2(1):10-14.

GENG Longxiang,CAO Yushan.Interpretation of the calculation and evaluation of shale gas resources/reserves[J].Unconventional Oil & Gas,2015,2(1):10-14.

[21] LI Y,LI X,WANG Y,et al.Effects of composition and pore structure on the reservoir gas capacity of Carboniferous shale from Qaidam Basin,China[J].Marine & Petroleum Geology,2015,62:44-57.

[22] CHALMERS G R L,BUSTIN R M.The organic matter distribution and methane capacity of the Lower Cretaceous strata of Northeastern British Columbia,Canada[J].International Journal of Coal Geology,2007,70(1-3):223-239.

[23] YANG F,NING Z,ZHANG R,et al.Investigations on the methane sorption capacity of marine shales from Sichuan Basin,China[J].International Journal of Coal Geology,2015,146:104-117.

[24] TIAN H,LI T,ZHANG T,et al.Characterization of methane adsorption on overmature Lower Silurian-Upper Ordovician shales in Sichuan Basin,southwest China:Experimental results and geological implications[J].International Journal of Coal Geology,2016,156:36-49.

[25] GUO H,JIA W,PENG P A,et al.The composition and its impact on the methane sorption of lacustrine shales from the Upper Triassic Yanchang Formation,Ordos Basin,China[J].Marine & Petroleum Geology,2014,57(2):509-520.

[26] LIU Y,ZHU Y.Comparison of pore characteristics in the coal and shale reservoirs of Taiyuan Formation,Qinshui Basin,China[J].International Journal of Coal Science & Technology,2016,3(3):330-338.

[27] HOU P,JU Y,GAO F,et al.Simulation and visualization of the displacement between CO2 and formation fluids at pore-scale levels and its application to the recovery of shale gas[J].International Journal of Coal Science & Technology,2016,3(4):351-369.

[28] ZHANG T,ELLIS G S,RUPPEL S C,et al.Effect of organic-matter type and thermal maturity on methane adsorption in shale-gas systems[J].Organic Geochemistry,2012,47(6):120-131.

[29] JI L,ZHANG T,MILLIKEN K L,et al.Experimental investigation of main controls to methane adsorption in clay-rich rocks[J].Applied Geochemistry,2012,27(12):2533-2545.

[30] SETZMANN U,WAGNER W.A new equation of state and tables of thermodynamic properties for methane covering the range from the melting line to 625 K at pressures up to 100 MPa[J].Journal of Physical & Chemical Reference Data,1991,20(6):1061-1155.

[31] KUNZ O,WAGNER W.The GERG-2008 wide-range equation of state for natural gases and other mixtures:An expansion of GERG-2004[J].Journal of Chemical & Engineering Data,2012,57(11):3032-3091.

[32] ETTINGERI L,DMITRIEV A M,SHAUPAKHINA E S.Systemic handbook for the determination of the methane content of coal seams from the seam pressure of the gas and the methane capacity of coal[J].Institute of Mining,Academy of Sciences,USSR,US Bureau of Mines Translation,1958(1505).

[33] CROSDALE P J,BEAMISH B B,VALIX M.Coalbed methane sorption related to coal composition[J].International Journal of Coal Geology,1998,35(1-4):147-158.

[34] CHEN D,PAN Z,LIU J,et al.Modeling and simulation of moisture effect on gas storage and transport in coal seams[J].Energy & Fuels,2012,26(3):1695-1706.

[35] 李昂,石文睿,袁志华,等.涪陵页岩气田焦石坝海相页岩气富集主控因素分析[J].非常规油气,2016,3(1):27-34.

LI Ang,SHI Wenrui,YUAN Zhihua,et al.Main factors controlling marine shale gas accumulation in Jiaoshiba shale gas field of Fuling area[J].Unconventional Oil & Gas,2016,3(1):27-34.

[36] 郭彤楼.涪陵页岩气田发现的启示与思考[J].地学前缘,2016,23(1):29-43.

GUO Tonglou.Discovery and characteristics of the Fuling shale gas field and its enlightenment and thinking[J].Earth Science Frontiers,2016,23(1):29-43.

[37] 张金川,聂海宽,徐波,等.四川盆地页岩气成藏地质条件[J].天然气工业,2008,28(2):151-156,179-180.

ZHANG Jinchuan,NIE Haikuan,XU Bo,et al.Geological condition of shale gas accumulation in Sichuan Basin[J].Natural Gas Industry,2008,28(2):151-156,179-180.

[38] 张士万,孟志勇,郭战峰,等.涪陵地区龙马溪组页岩储层特征及其发育主控因素[J].天然气工业,2014,34(12):16-24.

ZHANG Shiwan,MENG Zhiyong,GUO Zhanfeng,et al.Characteristics and major controlling factors of shale reservoirs in the Longmaxi Fm,Fuling area,Sichuan Basin[J].Natural Gas Industry,2014,34(12):16-24.

[39] 李湘涛,石文睿,郭美瑜,等.涪陵页岩气田焦石坝区海相页岩气层特征研究[J].石油天然气学报,2014,36(11):11-15,4.

LI Xiangtao,SHI Wenrui,GUO Meiyu,et al.Characteristics of marine shale gas reservoirs in Jiaoshiba Area of Fuling shale gas field[J].Journal of Oil and Gas Technology,2014,36(11):11-15,4.

[40] 戴方尧,郝芳,胡海燕,等.川东焦石坝五峰-龙马溪组页岩气赋存机理及其主控因素[J].地球科学,2017,42(7):1185.

DAI Fangyao,HAO Fang,HU Haiyan,et al.Occurrence mechanism and key controlling factors of Wufeng-Longmaxi shale gas,eastern Sichuan Basin[J].Earth Science,2017,42(7):1185.

[41] 刘雄辉.页岩岩石学特征及其对吸附气量的影响[D].成都:西南石油大学,2015.

LIU Xionghui.Petrological characteristics of shale and its influence on the amount of adsorbed gas[D].Chengdu:Southwest Petroleum University,2015.

[42] 郭旭升.涪陵页岩气田焦石坝区块富集机理与勘探技术[M].北京:科学出版社,2014.

GUO Xusheng.Enrichment model and exploration technology in Jiaoshiba area of Fuling gas field[M].Beijing:Science Press,2014.

[43] 陈乐求.焦石坝页岩声学、气体吸附和孔渗特性实验研究[D].广州:华南理工大学,2016.

CHEN Leqiu.Experimental study on the characteristics of acoustic,gas adsorption and seepage flow of shale in Jiaoshiba[D].Guangzhou:South China University of Technology,2016.

[44] 韩辉,李大华,马勇,等.四川盆地东北地区下寒武统海相页岩气成因:来自气体组分和碳同位素组成的启示[J].石油学报,2013,34(3):453-459.

HAN Hui,LI Dahua,MA Yong,et al.The origin of marine shale gas in the northeastern Sichuan Basin,China:Implications from chemical composition and stable carbon isotope of desorbed gas[J].Acta Petrolei Sinica,2013,34(3):453-459.

[45] 杨文新,李继庆,苟群芳,等.四川盆地焦石坝地区页岩吸附特征室内实验[J].天然气地球科学,2017,28(9):1350-1355.

YANG Wenxin,LI Jiqing,GOU Qunfang,et al.Experiment study on shale adsorption properties for Jiaoshiba shale,Sichuan Basin[J].Natural Gas Geoscience,2017,28(9):1350-1355.

[46] 张晓明,石万忠,徐清海,等.四川盆地焦石坝地区页岩气储层特征及控制因素[J].石油学报,2015,36(8):926-939,953.

ZHANG Xiaoming,SHI Wanzhong,XU Qinghai,et al.Reservoir characteristics and controlling factors of shale gas in Jiaoshiba area,Sichuan Basin[J].Acta Petrolei Sinica,2015,36(8):926-939,953.

[47] 郭旭升,李宇平,刘若冰,等.四川盆地焦石坝地区龙马溪组页岩微观孔隙结构特征及其控制因素[J].天然气工业,2014,34(6):9-16.

GUO Xusheng,LI Yuping,LIU Ruobing,et al.Characteristics and controlling factors of micro-pore structures of Longmaxi Shale play in the Jiaoshiba area,Sichuan Basin[J].Natural Gas Industry,2014,34(6):9-16.

[48] 崔永君.煤对CH4、N2、CO2及多组分气体吸附的研究[D].北京:煤炭科学研究总院,2003.

CUI Yongjun.Adsorption of CH4,N2,CO2 single and multicomponent gas on coal[D].Beijing:China Coal Research Institute,2003.