移动阅读

朱卫兵1,2,许家林2,陈 璐3,李 竹1,刘文涛4

(1.中国矿业大学 矿业工程学院,江苏 徐州 221116; 2.中国矿业大学 煤炭资源与安全开采国家重点实验室,江苏 徐州 221116; 3.中南大学 资源与安全工程学院,湖南 长沙 410083; 4.中煤能源集团 西安设计工程有限责任公司,陕西 西安 710054)

摘 要:针对我国西部矿区浅埋近距离煤层房采煤柱下开采时易发生工作面压架、地表台阶塌陷以及矿震灾害的现象,采用物理模拟及数值模拟方法对下煤层工作面采动时上覆房采煤柱群的动态失稳过程及工作面压架机理开展研究。实测统计榆阳区部分矿井本煤层房式开采后,只有当房采煤柱的弹性核区比例大于31%时,房采煤柱才能处于长期稳定。下煤层采后的模拟结果表明:上覆房采煤柱的破坏形式及其失稳次序同其与下煤层工作面相对位置密切相关,房采煤柱依次从工作面开切眼位置、工作面位置、采空区中部位置发生破坏及失稳,且工作面开切眼和工作面位置处煤柱多发生顺向采空区的斜切破坏,而采空区中部煤柱则发生垂向压裂破坏。根据石圪台煤矿数值模拟结果显示,上部2-2煤层房采后煤柱支承应力峰值由原岩应力2.8 MPa增大至12 MPa,应力集中系数为4.28;当下部3-1煤层工作面采后,上覆2-2煤层房采煤柱的支承应力峰值增大至30 MPa,应力集中系数达10.71;下煤层工作面开切眼侧与工作面正上方的房采煤柱呈现横向不均匀承载特征以及受水平拉伸变形影响,最终导致边界处房采煤柱易出现对角斜切破坏模式。两侧边界煤柱失稳后,其顶板岩层瞬间发生整体拉剪破断从而引发矿震,顶板多层岩层以“整体运动”的形式急剧快速下沉并撞击底板,将采空区中部上方的房采煤柱压垮压塌,同时巨大的冲击力进而导致上下煤层间的岩层发生全厚切落,造成下煤层工作面发生切顶压架。实验发现从上覆房采煤柱群首个煤柱发生破坏至整体失稳运动并达到稳定,历时仅约为0.45 s,其中,上下煤层之间的岩层发生全厚切落历时仅约为0.05 s。

关键词:浅埋深;近距离煤层;房式开采;煤柱失稳;压架;矿震

中图分类号:TD325

文献标志码:A

文章编号:0253-9993(2019)02-0358-09

收稿日期:2018-07-09

修回日期:2018-10-18

责任编辑:郭晓炜

基金项目:国家重点研发计划资助项目(2016YFC0501109);国家自然科学基金面上资助项目(41772313)

作者简介:朱卫兵(1978—),男,江苏海门人,副教授,博士。 E-mail:zweibing@163.com

朱卫兵,许家林,陈璐,等.浅埋近距离煤层开采房式煤柱群动态失稳致灾机制[J].煤炭学报,2019,44(2):358-366.doi:10.13225/j.cnki.jccs.2018.0907

ZHU Weibing,XU Jialin,CHEN Lu,et al.Mechanism of disaster induced by dynamic instability of coal pillar group in room-and-pillar mining of shallow and close coal seams[J].Journal of China Coal Society,2019,44(2):358-366.doi:10.13225/j.cnki.jccs.2018.0907

ZHU Weibing1,2,XU Jialin2,CHEN Lu3,LI Zhu1,LIU Wentao4

(1.School of Mines,China University of Mining and Technology,Xuzhou 221116,China; 2.Stafe Key Laboratory of Coal Resource and Safe Mining,China University of Mining and Technology,Xuzhou 221116,China; 3.School of Resources and Safety Engineering,Central South University,Changsha 410083,China; 4.Xi’an Design Engineering Co.,Ltd.,China Coal Energy Group,Xi’an 710054,China)

Abstract:In the western part of China,mine disasters such as support failure,surface stepped subsidence and mine earthquake,are prone to occur when lower coal seam is extracted which is closely beneath the coal pillars left after room-and-pillar mining with shallow overburden.In this paper,physical modelling and numerical simulation method were adopted to investigate the dynamic instability process of upper coal pillar group and the mechanism of support failure under the influence of lower coal seam mining.According to the measured statistics in some mines after coal mining of Yuyang District,only when the proportion of elastic core area of the coal pillars is greater than 31% can the room coal pillars keep long-term stability.The simulation result after mining lower coal seams shows that the failure form and instability sequence of the upper coal pillars have close relations with the positions relative to the lower coal seam working face.The damage and instability of room coal pillar occur in the positions of open-off cut,working face,and the middle of goaf successively.Furthermore,the coal pillars in the open-off cut and working face mostly show horizontal shear failure,while the coal pillars in the middle of the goaf show vertical fracturing damage.According to the numerical simulation results of Shigetai Coal Mine,the peak abutment pressure of coal pillar in upper 2-2 coal seam increases from in-situ stress 2.8 MPa to 12 MPa after coal mining with the stress concentration factor at 4.28.After the lower 3-1 coal seam working face mined,the peak abutment pressure of the retained pillar in upper 2-2 coal seam continually increases to 30 MPa with the stress concentration factor up to 10.71.The open-off cut side of the lower coal seam working face showed uneven horizontally bearing with the coal pillar directly above the lower coal seam working face and the influence of horizontal tensile deformation are the main reasons for the diagonal failure mode of the boundary coal pillars.After the instability of two sides coal pillars,the roof instantaneously occur overall shear breakage,causing mine earthquake,and multi-layered strata in the roof settled suddenly in the form of “rigid body motion” and hit against the floor,leading to the collapse of the room coal pillars in the middle of goaf.At the same time,the huge impact force further leads to the full cutting of the strata between the upper and lower coal seams,which results in the roof cutting and support failure in the lower coal seam working face.It was found in the experiment that there was only about 0.45 seconds from the failure of the first coal pillar in the overlying coal pillar group to the overall unstable movement and the final stability,among them,the full cutting of the strata between the upper and lower coal seams only took about 0.05 seconds.

Key words:shallow cover;close coal seams;room mining;instability of coal pillar;support failure;mine earthquake

我国西部小型矿井以往普遍采用房式开采,采空区遗留了大量的房采煤柱,为临近煤层的安全开采留下隐患。神东矿区大柳塔煤矿井田边界的局部区域就曾被地方小煤矿采用房式采煤法进行过越界开采,导致该矿22103工作面推进至上覆小窑房采煤柱时发生顶板压架事故[1];神东矿区石圪台煤矿资源整合后的部分井田开采区域面临浅部原小窑房采煤柱和集中大煤柱下开采,工作面也曾发生严重的压架灾害[2]。

国内众多学者对矿柱或煤柱的稳定性及其致灾机理进行了研究。周子龙等[3-4]通过室内试验及数值模拟研究,分析了“矿柱-顶板”联合支撑体系在变形破坏过程中矿柱间的应力转移及破坏特征。周子龙、朱德福等[5-6]采用重整化群方法,得到矿柱群系统整体失稳的临界概率,建立一种评价矿柱群整体稳定性的有效方法。许家林、鞠金峰等[7-9]研究了浅埋近距离下煤层工作面推出上覆集中煤柱的压架机理,认为上覆集中煤柱边界顶板的关键块体结构相对回转运动是引发下煤层工作面发生动载矿压的根本原因。陈苏社、杨俊哲等[10-14]认为上覆集中煤柱在下煤层工作面采动影响下发生突然失稳,破坏了下部岩层的铰接结构,造成房采煤柱下的动载。孟达、屠世浩等[15-16]建立力学模型,计算了煤柱-顶板联合承载体系中应力分布状态,房采煤柱下方综采工作面顶板岩层变形能空间分布和发育规律,从能量释放的角度解释了工作面压架机理。解兴智、魏立科、徐敬民等[17-20]通过现场微震监测,论述了房采煤柱上覆结构运动对下煤层工作面顶板岩层破断的影响,从应力传递的角度阐述了结构失稳后的载荷传递致使工作面发生压架。

纵观已有文献,均未涉及下煤层采动过程中上覆房采煤柱群的时空失稳特征,这包括:① 上覆房采煤柱破坏及失稳次序;② 房采煤柱顶板岩层运动特征及其对底板岩层作用规律;③ 房采煤柱失稳时下煤层顶板运动特征及工作面压架机理。而上述内容,对建立岩层运动与工作面动压的时空对应关系,预测工作面压架发生条件及位置至关重要。因此,有必要深入研究,为类似条件的工作面安全开采提供理论指导。

我国西部小窑房式开采创造极大经济效益的同时,也引起严重的地表塌陷灾害。据统计,榆林市榆阳区常兴井田共发生3次采空区大面积塌陷,塌陷面积总计6.31×105 m2;十八墩矿采空区塌陷引起两次矿震(中国地震台网中心监测震级分别为2.8级和3.2级),塌陷面积总计2.75×105 m2,榆林市震感明显,高层建筑大多发生轻微晃动。根据陕西地震信息网监测结果,自2009年9月至2015年底,榆林市榆阳区共监测到矿震13次,震级2.1~3.3级,其中2009年1次、2011年3次、2012年3次、2015年6次,上述矿震不仅对地表含水层、生态环境造成极大破坏,更对井上下人员生命安全造成极大威胁。西安设计院曾经对陕西省榆林市榆阳区采用房式开采的煤矿采空区塌陷情况进行过调研,为便于描述,“1”表示发生,而“-1”表示未发生,统计结果见表1。

表1 榆林榆阳区部分矿井地面塌陷情况统计

Table 1 Statistics of surface collapse cases in part of mines of Yuyang district,Yulin City

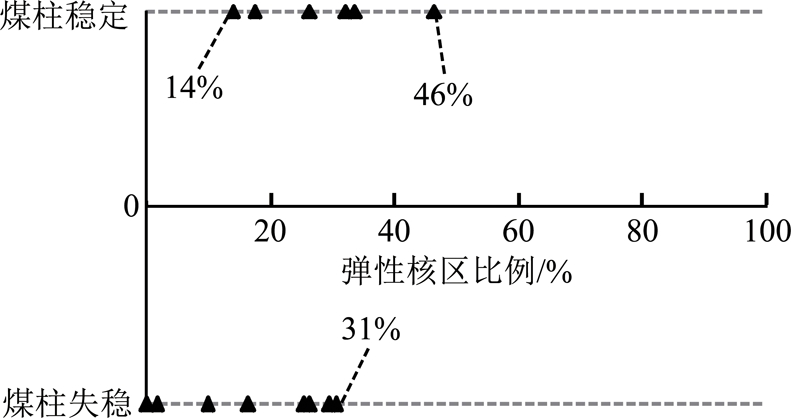

根据房采煤柱的尺寸(由采高,采宽和留宽决定)和埋藏深度,采用威尔逊公式计算表1中煤柱的塑性区宽度,据此得出房采煤柱的弹性核区宽度以及弹性核区率。表1中不同弹性核区率条件下煤柱失稳与否的对应关系如图1所示。由此可知,当房采煤柱的弹性核区比例小于14%时,矿井的遗留煤柱均会失稳,地面出现塌陷;当弹性核区比例介于14%~31%时,部分矿井遗留煤柱失稳,部分矿井遗留煤柱稳定;当煤柱弹性核区比例大于31%时,矿井遗留煤柱均处于稳定状态,地面暂无塌陷。

图1 不同弹性核区率条件下煤柱稳定性结果

Fig.1 Stability results of coal pillars under the condition of different elastic nuclear area proportions

事实上,处于初次采动期间的房采煤柱有时候会间隔几年甚至十几年才发生多米诺骨牌效应的连锁失稳现象。而多数煤矿实际可回采的煤层数目较多,当回收房采煤柱下部的煤层时,必然会面临上覆房采煤柱稳定性影响下煤层安全开采的问题。文献[8-9,16,20]均涉及到房采煤柱下开采引发的动载矿压,甚至压架事故。

通过物理模拟研究近距离煤层开采时上覆房采煤柱破坏次序及煤柱群动态失稳过程。物理模型长度120 cm,宽度8 cm,高度42 cm。模型的几何相似比1∶100,密度相似比1∶1.6,应力相似比1∶160。根据神东矿区石圪台煤矿不同岩层地质赋存条件及其物理力学参数[20],确定物理模型中各岩层厚度及材料配比见表2。物理模拟材料以河砂、云母做骨料,以碳酸钙和石膏做胶结料,在煤层中则加入一定比例的粉煤灰。模型顶板采用铁块加载的方式对模型进行补偿加载,用以模拟130 m埋深。

煤层开采前,先将2-2煤层进行房式开采。由于相似模拟为二维模型,在设计煤柱尺寸时,应考虑从三维(实际开采情况)向二维(相似模型)转化煤柱尺寸的问题。徐敬民[20]定义了煤柱的“控顶率”,即单一煤柱等效支撑顶板的范围。在本相似模型中,房采煤柱留设宽度为2.7 cm,间隔为7.5 cm,与上述案例统计结果基本保持一致。左侧边界煤柱宽度为5.2 cm,右侧边界煤柱宽度为5.3 cm。在3-1煤层回采过程中,通过间隔拍照及高速摄影技术进行实时记录,下煤层回采时上覆房采煤柱群动态失稳过程如图2所示。

表2 模型各岩层相似材料配比

Table 2 Similar material mixture of each stratum in physical simulation

图2 房采煤柱群动态失稳过程

Fig.2 Process of dynamic instability of room coal pillar group

图2展示了相似模拟实验中房采煤柱群不同位置煤柱破坏形式及其动态失稳过程。下煤层回采过程中,上覆房采煤柱先后失稳,其对应的失稳次序为:煤柱②→煤柱①→煤柱⑥→煤柱⑤→煤柱③和煤柱④。首先是下煤层开切眼正上方位于采空区侧的房采煤柱②发生朝向采空区的斜切破坏,其次是其邻近在实体煤上方的房采煤柱①发生失稳,如图2(c),(d)所示;接着工作面上方房采煤柱⑥出现朝向采空区的斜切破坏,然后是工作面上方的房采煤柱⑤发生失稳,如图2(e),(f)所示;最后是采空区上方的房采煤柱③和煤柱④出现垂向压裂破坏并崩塌,如图2(g)所示。

根据图2(e)~(h)中房采煤柱顶板岩层的破断形式及其运动特征可以看出,在煤柱③和煤柱④坍塌前,房采煤柱上方的顶板岩层呈现出整体挠曲下沉的现象,而在煤柱③和煤柱④坍塌的瞬间,伴随出现多层顶板岩层整体、全厚切落的特征。与此同时,房采煤柱顶、底板出现猛烈的撞击,引起坍塌煤柱碎屑的喷出,并引发矿震;若岩体的全厚切落导致采动裂隙沟通至上覆含水层或地表,会导致地下水流失以及地表大面积塌陷坑的出现,将引起生态环境承载力已较为脆弱的西部地区更为恶化。

根据录像的慢放功能及提取的每一帧图片,再现了房采煤柱群动态失稳的顶底板运动过程,如图3所示。从上覆房采煤柱群首个煤柱发生破坏至整体失稳运动并达到稳定,历时仅约为0.45 s,其中,上下煤层之间的岩层发生全厚切落历时仅约为0.05 s。显然,这一失稳过程持续时间极短,几乎可以等同于瞬间发生,且失稳过程的累计持续时间越短,上覆岩层对下方岩层的冲击越大,所造成的灾害程度也会越大。

图3 房采煤柱顶底板岩层破断运动

Fig.3 Fracture movement of roof and floor around room coal pillars

在上覆房采煤柱动态失稳过程中,层间岩层的破断块体起初能够和煤壁上方的岩块咬合形成临时稳定的结构。但是,当采空区上方的房采煤柱弹指间被完全压垮以后,房采煤柱顶板岩层在自重及载荷作用下急速下沉,并和底板岩层发生猛烈碰撞,此时不仅将房采煤柱完全压成粉末,还将上覆岩层因急速下沉而产生的冲量传递至层间岩层,进而导致层间岩层沿煤壁发生全厚切落,造成下煤层工作面发生切顶压架。同时,地面形成台阶状塌陷坑。房采煤柱动态失稳的简化示意如图4所示。

采用UDEC离散元软件研究近距离煤层房采煤柱下开采时,房采煤柱群位移场与应力场的变化规律,揭示不同位置房采煤柱的破坏形式及房采煤柱群的动态失稳机制。模型长200 m,高75 m。其中上部2-2煤层厚度5 m,下部3-1煤层厚度4 m,底板累计厚度18 m。考虑到物理模拟与数值模拟在尺度上应具有的相似性,在数值模拟中设计2-2煤层中的房采煤柱宽度4 m,煤柱间隔6 m。采用位移边界分别固定两边侧面的水平移动以及底部的垂直移动。模型采用弹塑性本构关系,材料服从Mohr-Coulomb强度准则,不同岩性岩层的材料力学与节理参数见文献[20]。将2 MPa均布载荷直接补偿加载在模型的顶界面,以模拟3-1煤层赋存的130 m埋深条件。

为监测3-1煤层回采过程中,2-2煤层房采煤柱及边界煤柱的受力状况及垂直应力变化,在房采煤柱1~17号中部和右侧边界煤柱各布置1个监测点,共计18个监测点,如图5中绿色标号所示;同时,在煤柱1~17号和右侧边界煤柱顶界面和底界面各布置一个位移观测点,对应于两条观测线,如图5中红色和紫色观测线所示。模型初始平衡之后,首先在上覆2-2煤层中进行房式开采,采6 m、留4 m,总共留设了17个房采煤柱;待覆岩运动稳定后再回采3-1煤层,首次开采步距为12 m,之后的开采步距均为6 m。

图6给出了3-1煤层工作面不同推进位置时,2-2煤层房采煤柱中不同计算单元弹塑性展布状态。图6(a)对应的3-1煤层工作面推进距离为42 m,此时仅有煤柱4首先发生破裂;图6(b)对应的工作面推进距离为48 m,此刻煤柱4和煤柱10都处于破坏失稳状态。数值模拟结果表明,首先是下煤层开切眼正上方对应的房采煤柱发生破坏失稳,其次才是工作面正上方的房采煤柱发生破坏失稳,最后是采空区中部房采煤柱发生破坏失稳,这与上述物理模拟结果基本一致。

图4 房采煤柱动态失稳示意

Fig.4 Schematic diagram of dynamic instability of room coal pillars

图5 位移测线与应力测点布置

Fig.5 Site plan of displacement measuring line and stress station in numerical model

图6 房采煤柱破坏失稳次序

Fig.6 Variation order of failure and instability of room coal pillars

图7为工作面推进至48 m时煤柱失稳前、后的垂直应力云图。模型初始平衡后2-2煤层原岩应力为2.8 MPa,待2-2煤层房式开采后,煤柱承受的支承应力峰值为12 MPa,应力集中系数4.28;当下煤层开挖48 m后,煤柱上的支承应力峰值增大至30 MPa(图7(a)),应力集中系数为10.71。说明在下煤层回采过程中,上覆房采煤柱所承受的载荷进一步增大,与本煤层房式开采相比增加了150%。在如此大的载荷作用下,房采煤柱必然会相继快速发生破坏失稳。在房采煤柱失稳之前,3-1煤层采空区上部的煤柱6~煤柱9均处于卸荷状态,而两侧的煤柱4、煤柱5以及煤柱10和煤柱11则处于高负荷承载状态;房采煤柱失稳后,煤柱4、煤柱5以及煤柱10之上的承载应力迅速转移至实体煤一侧的煤柱2、煤柱3以及煤柱11和煤柱12之上,达到新的平衡,如图7(b)所示。

图8列出了上覆房采煤柱1~15在下煤层推进过程中的垂直应力变化曲线。由图8可知,左侧煤柱1、右侧煤柱14,15的垂直应力曲线基本保持不变,说明几乎未受到下煤层的采动影响;左侧煤柱2、右侧煤柱13受到下煤层采动轻微影响;处于采空区上方的煤柱6,7,8,9处于卸荷状态,虽然这些煤柱能够保持暂时稳定,但是一旦下部岩层触底之后,在煤柱上覆岩层的集中荷载作用下,这些煤柱最终也会破坏失稳;左侧煤柱4所受的载荷较大且最先发生破裂损坏,右侧煤柱10所受的载荷最大也发生了破裂损坏。

图7 房采煤柱失稳前、后的垂直应力云图

Fig.7 Vertical stress nephogram of full model

图8 各房采煤柱所受垂直应力的变化

Fig.8 Variation of vertical stress inflicted on each room coal pillar

图9展示了煤柱10破坏失稳之前内部的垂直应力分布,煤柱10在采空区右侧的实体煤上部,煤柱内部的左上角出现最大垂直应力约30 MPa,从该煤柱的左上角至右下角,煤柱内部所承受的垂直应力递减至13 MPa,鉴于图2中房采煤柱5所呈现出的破坏特征,可知数值模拟中煤柱10的破坏形式也呈现出朝向采空区的对角斜切破坏,煤柱破裂线预计如图9所示。煤柱内部不同位置的非均匀承载可能致使煤柱更易发生对角压剪破坏,导致下煤层两侧实体煤上部的房采煤柱斜切破坏面始终是倾向或朝采空区一侧。

图10为下煤层工作面推进至48 m时2-2煤层各房采煤柱顶底板的位移变化曲线。由图10可知,煤柱顶底板的下沉量基本相近,但是仍然有5.97~10.98 mm的竖直位移变化,其中在采空区两侧实体煤上部的房采煤柱轴向均出现压缩,最大压缩量是10号煤柱对应的5.97 mm,采空区上方的煤柱6~煤柱9轴向则出现拉伸,应该是煤柱卸荷后发生部分回弹变形。根据图10(d)得出,两侧实体煤上部的房采煤柱顶底界面同时受水平拉伸变形影响,左侧最大水平变形是4号煤柱对应的1.75 mm/m,右侧最大水平变形是10号煤柱对应的0.24 mm/m。正是由于下煤层开采边界正上方的房采煤柱所受的垂直应力显著增大,且其还受水平方向的拉伸变形影响,导致下煤层采空区两侧实体煤上部的房采煤柱呈现出偏向采空区的对角斜切破坏特征,当此边界煤柱失稳后,上覆岩层载荷作用下引发中部煤柱的垂直压裂及失稳,导致房采煤柱群的整体失稳,引发矿震、压架以及地表塌陷等灾害。

图9 煤柱10内部的垂直应力分布

Fig.9 Vertical stress distribution in the interior of No.10 coal pillar

图10 各房采煤柱顶界与底界位移及变形曲线

Fig.10 Displacement deformation curves of top and bottom boundaries around room coal pillars

(1)浅埋近距离煤层房采煤柱下开采上覆房采煤柱的破坏次序为:首先,下煤层开切眼上方房采煤柱发生朝向采空区的对角斜切破坏;其次,工作面上方房采煤柱发生朝向采空区的对角斜切破坏,最后,采空区中部房采煤柱出现压裂破坏,煤柱破坏次序反映了煤柱上覆载荷的动态迁移过程。

(2)阐明了房采煤柱失稳过程中顶、底板相互作用及房采煤柱群失稳对矿震、工作面压架的作用机制。采空区中部房采煤柱失稳前,顶板岩层处于整体挠曲下沉状态;失稳时,顶板岩层瞬间整体拉剪破断,急速下沉撞击底板;受此冲击,层间岩层沿煤壁出现全厚切落,导致下煤层工作面切顶压架。

(3)石圪台煤矿模拟结果表明,本煤层采后房采煤柱应力集中系数为4.28;下煤层开采时,房采煤柱应力集中系数增大至10.71。受岩层挠曲下沉的影响,下煤层工作面开切眼侧及工作面正上方房采煤柱承受横向不均匀的轴向压力,是边界处房采煤柱发生对角斜切破坏模式的主要原因。

参考文献

[1] 鞠金峰,许家林,朱卫兵,等.大柳塔煤矿22103综采面压架机理及防治技术[J].煤炭科学技术,2012,40(2):4-7.

JU Jinfeng,XU Jialin,ZHU Weibing,et al.Hydraulic powered support jammed mechanism and prevention technology of fully mechanized coal mining face in Daliuta mine[J].Coal Science and Technology,2012,40(2):4-7.

[2] ZHU Weibing,XU Jingmin,LI Yingchun.Mechanism of the dynamic pressure caused by the instability of upper chamber coal pillars in Shendong coalfield,China[J].Geosciences Journal,2017,21:729-741.

[3] ZHOU Zilong,CHEN Lu,CAI Xin,et al.Experimental investigation of the progressive failure of multiple pillar-roof system[J].Rock Mechanics and Rock Engineering,2018,51(5):1629-1636.

[4] ZHOU Zilong,CHEN Lu,ZHAO Yuan,et al.Experimental and numerical investigation on the bearing and failure mechanism of multiple pillars under overburden[J].Rock Mechanics and Rock Engineering,2017,50:995-1010.

[5] 周子龙,李夕兵,赵国彦.民窿空区群级联失稳评价[J].自然灾害学报,2007,16(5):91-95.

ZHOU Zilong,LI Xibing,ZHAO Guoyan.Evaluation of cascading collapse for private mined zone groups[J].Journal of Natural Disasters,2007,16(5):91-95.

[6] 朱德福,屠世浩,王方田,等.浅埋房式采空区煤柱群稳定性评价[J].煤炭学报,2018,43(2):390-397.

ZHU Defu,TU Shihao,WANG Fangtian,et al.Stability evaluation on pillar system of room and pillar mining in goaf at shallow depth seam[J].Journal of China Coal Society,2018,43(2):390-397.

[7] 许家林,朱卫兵,鞠金峰.浅埋煤层开采压架类型[J].煤炭学报,2014,39(8):1625-1634.

XU Jialin,ZHU Weibing,JU Jinfeng.Supports crushing types in the longwall mining of shallow seams[J].Journal of China Coal Society,2014,39(8):1625-1634.

[8] 鞠金峰,许家林.浅埋近距离煤层出煤柱开采压架防治对策[J].采矿与安全工程学报,2013,30(3):323-330.

JU Jinfeng,XU Jialin.Prevention measures for support crushing while mining out the upper coal pillar in close distance shallow seams[J].Journal of Mining & Safety Engineering,2013,30(3):323-330.

[9] XU Jialin,XUAN Dayang,HE Changchun.Innovative backfilling longwall panel layout for better subsidence control effect-separating adjacent subcritical panels with pillars[J].International Journal of Coal Science & Technology,2014,1(3):297-305.

[10] 陈苏社.综采工作面过上层煤集中煤柱动载矿压控制技术[J].煤炭科学技术,2014,42(6):140-143.

CHEN Sushe.Dynamic mine strata pressure control technology of full-mechanized coal mining face passing through concentrated coal pillars in above seam[J].Coal Science and Technology,2014,42(6):140-143.

[11] 杨俊哲.浅埋近距离煤层过上覆采空区及煤柱动压防治技术[J].煤炭科学技术,2015,43(6):9-13.

YANG Junzhe.Dynamic pressure prevention and control technology of coal mining face with shallow depth and contiguous seams passing through overburden goaf and coal pillars[J].Coal Science and Technology,2015,43(6):9-13.

[12] 李浩荡,杨汉宏,张斌,等.浅埋房式采空区集中煤柱下综采动载控制研究[J].煤炭学报,2015,40(S1):6-11.

LI Haodang,YANG Hanhong,ZHANG Bin,et al.Control study of strong strata behaviors during the fully mechanized working face out of concentrated coal pillar in a shallow depth seam in proximity beneath a room mining goaf[J].Journal of China Coal Society,2015,40(S1):6-11.

[13] 肖剑儒,李少刚,张彬,等.浅埋深煤层房采区下综采工作面动压控制技术[J].煤炭科学技术,2014,42(10):20-23.

XIAO Jianru,LI Shaogang,ZHANG Bin,et al.Control technology of dynamic mine strate pressure of fully-mechanized coal mining face under gob left by room and pillar mining of shallow depth seam[J].Coal Science and Technology,2014,42(10):20-23.

[14] ZHU W,XU J,XU G.Mechanism and control of roof fall and support failure incidents occurring near longwall recovery roadways[J].Journal of the Southern African Institute of Mining and Metallurgy,2017,117:1063-1072.

[15] 孟达,王家臣,王进学.房柱式开采上覆岩层破坏与垮落机理[J].煤炭学报,2007,32(6):577-580.

MENG Da,WANG Jiachen,WANG Jinxue.Mechanism on the failure and caving of roof strata in pillar and house mining[J].Journal of China Coal Society,2007,32(6):577-580.

[16] 屠世浩,窦凤金,万志军,等.浅埋房柱式采空区下近距离煤层综采顶板控制技术[J].煤炭学报,2011,36(3):366-370.

TU Shihao,DOU Fengjin,WAN Zhijun,et al.Strata control technology of the fully mechanized face in shallow coal seam close to the above room-and-pillar gob[J].Journal of China Coal Society,2011,36(3):366-370.

[17] 解兴智.浅埋煤层房柱式采空区下长壁开采矿压显现特征[J].煤炭学报,2012,37(6):898-902.

XIE Xingzhi.Study on the characteristics of strata behavior in shallow seam longwall mining under the room-and-pillar mining goaf[J].Journal of China Coal Society,2012,37(6):898-902.

[18] 魏立科,张彬,付兴玉,等.房式采空区下特殊岩梁结构支架工作阻力分析[J].岩石力学与工程学报,2015,34(10):2142-2147.

WEI Like,ZHANG Bin,FU Xingyu,et al.Support resistance analysis for special roof structures under room mining goaf[J].Chinese Journal of Rock Mechanics and Engineering,2015,34(10):2142-2147.

[19] WEI L,QI Q,LI H,et al.A case study of damage energy analysis and an early warning by microseismic monitoring for large area roof caving in shallow depth seams[J].Shock and Vibration,2015,2015:1-9.

[20] 徐敬民,朱卫兵,鞠金峰.浅埋房采区下近距离煤层开采动载矿压机理[J].煤炭学报,2017,42(2):500-509.

XU Jingmin,ZHU Weibing,JU Jinfeng.Mechanism of dynamic mine pressure occurring below adjacent upper chamber mining goaf with shallow cover depth[J].Journal of China Coal Society,2017,42(2):500-509.