以“煤基液体燃料”和煤化工多联产为目标的新型煤转化技术是我国煤炭高效洁净利用的发展方向和亟需解决的重大问题之一[1-6]。其中煤炭间接液化技术反应条件相对温和,可同时生产油品及化工产品,市场竞争力强,是煤化工领域重要的发展方向[7]。费托合成反应是煤炭间接液化技术的关键环节[8-9],国家能源集团宁夏煤业400万t/a和延长石油15万t/a的费托合成装置分别采用的是铁基催化剂和钴基催化剂浆态床技术[10]。虽然费托合成反应器都采用浆态床,但2种催化剂配套的还原工艺却不同。目前铁基催化剂浆态床反应器配套的还原装置同样采用浆态床,而钴基催化剂由于还原温度在400~450 ℃,需要采用气固流化床反应器。浆态床还原反应器具有结构简单、床层温度均匀,压降小、易于操控等优点,但是存在还原周期长、还原能力小、无法离线存储等问题。以宁煤400万t/a费托合成装置为例,采用浆态床还原整体开工周期需20 d左右。而气固流化床还原技术,虽然对催化剂的耐磨性和床层控制有较高要求,易出现还原不完全、局部飞温、催化剂烧结等问题,但如果能够根据催化剂的综合性能选择适合的流化状态,其操作弹性范围宽、生产能力大、传质、传热效果好等优势也相当明显[7]。同样以宁煤400万t/a费托合成装置为例,若采用同等直径的流化床还原反应器,单批次还原能力可提高2~3倍且还原时间缩短50%,再结合离线储存特点可将开工周期缩短到5~10 d。因此,如果能够充分研究流态化对费托铁基催化剂颗粒物性的依赖关系,并结合催化裂化等相关领域成熟的流化床技术应用[11-18],开发铁基催化剂的气固流化床还原技术,将产生巨大的经济效益。

笔者对自主研发的费托铁基工业催化剂气固流态化特性进行了常温常压条件下冷模研究,并与广泛应用的催化裂化催化剂的流态化行为进行了对比[19],结合催化剂的物性参数获得了不同流型的流化特性和临界速度。由于是冷模研究,为便于观察和测量采用有机玻璃装置,未能考察温度和压力条件对床层流化特性的影响,为此笔者进一步在能够加热和承压的不锈钢反应器中考察工艺条件对催化剂流化特性的影响。研究结果更接近真实还原反应工况,可为开发大规模的气固流化床还原技术提供重要依据。

1 原料及实验部分

1.1 催化剂及原料气

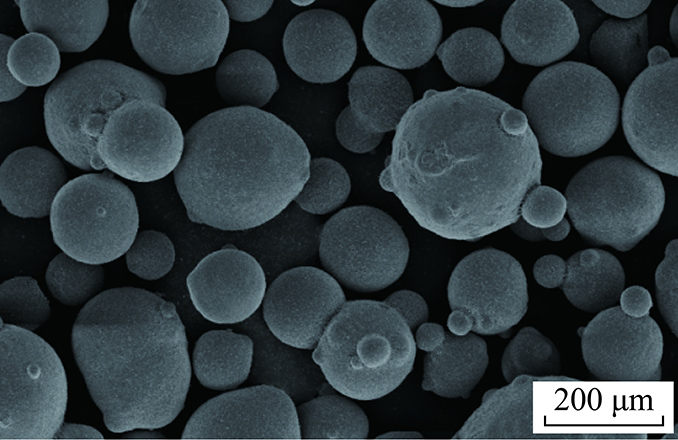

图1为试验采用的自主研发的费托合成催化剂的扫描电镜图。由图1可知,催化剂颗粒近球形,表面较光滑,粒径大小不同,主要集中在50~100 μm。粒度分析结果表明,催化剂颗粒粒径从20~100 μm 均有分布,平均粒径为75 μm。相关详细参数见文献[19]。按照Geldart分类方法,本试验的铁基催化剂属于A类颗粒,如图2所示。

图1 铁基催化剂扫描电镜图

Fig.1 SEM image of F-T catalyst

图2 F-T催化剂Geldart分类

Fig.2 Geldart classification for F-T catalyst

本研究针对催化剂的流化特性进行考察,不考虑反应性能,因此采用一定比例混合的H2和N2模拟合成气组分作为原料气。

1.2 实验装置工艺流程

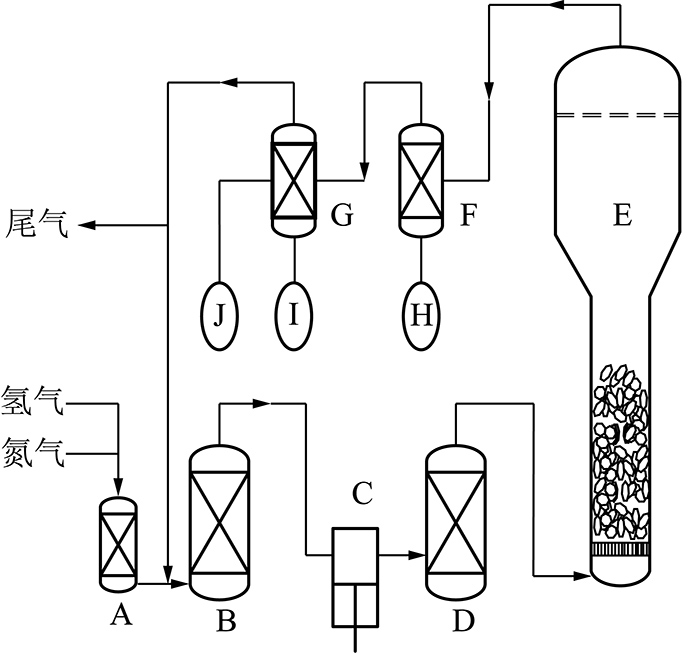

图3为气固流化床实验装置工艺流程图。其流程如下:合成气模拟气体H2和N2经过质量流量计计量后进入新鲜气混合罐,之后进入压缩机前缓冲罐,经压缩机升压后,进入压缩机出口缓冲罐,之后进入反应器底部,反应器底部设有气体分布器,之后气体通过催化剂床层;气体出反应器后,经过气液分离罐后,作为循环气返回压缩机入口缓冲罐。当采用合成气进行实际反应时,会将部分循环气作为尾气外排,反应的液体产物进入产品罐。反应器入口安装有流量计计量入塔气流量。

图3 气固流化床工艺流程

Fig.3 Process diagram of gas-solid fluidized bed A—新鲜气混合罐;B—压缩机前缓冲罐;C—压缩机;D—压缩机 出口缓冲罐;E—反应器;F,G—气液分离罐;H,I,J—产品罐

1.3 气固流化床反应器构造

图4为气固流化床反应器结构尺寸图。反应器由密相反应区和扩径沉降区2部分构成,其中密相反应区高度为2.38 m,内径71 mm,扩径沉降区高度为4.19 m,内径109 mm。反应器轴向分布有6个压差计(Δp1~Δp6)用于测定反应器内各段压差,其中Δp1对应气体分布器压差。压差计型号为罗斯蒙特3051CD2A系列,DCS数值点记录频次为1次/s。

图4 流化床反应器结构

Fig.4 Diagram of gas-solid fluidized bed

反应器最高工作压力为3.0 MPa。为了后续讨论描述方便,将Δp2~Δp6各压差所对应床层(H2~H6段)的床层密度定义为ρH2,ρH3,ρH4,ρH5,ρH6。

2 结果与讨论

2.1 操作压力对床层压差脉动幅值的影响

流化床操作压力的变化会影响流化床内许多基本特性,如床内的气泡形态、压差脉动幅值等。图5为表观气速u在0.30,0.33和0.43 m/s的条件下,操作压力p对床层总压差脉动幅值的影响结果。由图5可知,压力增大,床层压差脉动幅值明显变小。这是由于当气固流化床内的压力高于特征压力Pc后,随着操作压力升高,床层中气泡破碎程度会加剧并超过气泡合并的程度、致使气泡变小所导致[7,20-23]。

图5 不同压力条件下床层压差脉动幅值

Fig.5 Variation of bed pressure fluctuation with different pressure

2.2 表观气速对床层气固分布的影响

文献研究表明[7],提高操作压力会促进床层内气泡破碎、影响流型转变速度。本节考察了在反应器最高工作压力3.0 MPa条件下,表观气速在0.06~0.64 m/s变化时床层的气固分布的变化规律。实验中催化剂藏量为4 kg,催化剂堆积高度1.06 m,床层顶部处于反应器H3段内。

图6为不同表观气速下反应器轴向各段床层空隙率和床层密度的变化趋势。由图6(a)可知,反应器密相段H2和H3段的床层空隙率随着表观气速的增加而增加,最小值为0.53,最大为0.65,这也与图6(b)中床层密度ρH2和ρH3逐渐降低的规律性相吻合。此段床层空隙率的增加是由表观气速增加造成床层膨胀、形成流化状态导致。对于密相段上段H4段,图6(a)表明空隙率随着表观气速的增加呈现先降低后增加的趋势,结合图6(b)催化剂床层密度结果能够更加清晰地发现这一规律,图6(b)同时表明,H4段床层密度最大值出现在0.39 m/s附近。虽然0.08 m/s时催化剂已经进入H4段,0.20 m/s以后催化剂开始进入H5段,但当表观气速为0.39 m/s及以下的范围时,密相床层顶部高度仍主要处于H4段以内,因此表观气速的增加造成了H4段固体催化剂颗粒增加,空隙率下降;当表观气速进一步增加时,床层高度进入H5段,H4段空隙率则随着整个床层空隙率的增加而增加。

图6 表观气速对床层空隙率和床层密度影响

Fig.6 Axial distribution of voidage and solids holdup with different superficial velocity

整体观察图6(a)每个表观气速条件下空隙率沿反应器轴向的分布,可以发现床层从鼓泡态逐渐过渡到湍动态的一个过程。当表观气速在0.06~0.08 m/s时,从H3段到H4段的空隙率变化明显有1个台阶存在,表明催化剂床层顶部与稀相区界面清晰,此时反应器床层处于鼓泡流化态。当表观气速大于0.20 m/s后,台阶变化过程逐步消失,床层轴向空隙率从下到上呈均匀倾斜增加,表明反应器内催化剂床层逐渐向湍动态区域过渡。

鼓泡流化向湍动流化转变可以使用起始湍动速度Uc来预测,文献[7,24]总结了相关的各种经验关联式,通过对公式适用性进行筛选,本文采用其中YERUSHALMI和CANKURT提出的关联式:

Uc=3.0(ρpdp)0.5-0.77

(1)

其中,ρp为颗粒密度;dp为颗粒尺寸。据此公式计算本实验的Uc为0.26 m/s。

为了进一步分析不同表观气速下气固流化床内的流动过程,结合已有文献研究[25-27],笔者选用双流体模型(Two-Fluid Model,TFM)对气固流化过程进行模拟,曳力模型选用的是EMMS-bubbling[28-29]介尺度模型。经过网格无关性验证并适当调整,最终选用网格数为267 540个。边界条件以及模拟的相关参数见表1。

表1 边界条件设置及模拟相关参数

Table 1 Boundary conditions and parameters

参数值Inlet boundaryVelocity inletOutlet boundaryPressure outletWall boundaryNo slipDrag modelEMMS-bubblingViscous modelLaminarUnsteady formulationFirst-order implicitPressure-velocity couplingPhase coupled SIMPLEMomentum discretizationSecond-order upwindVolumne fraction discretizationQuickGranular temperatureAlgebraicTime step/s5×10-4

图7为3.0 MPa压力下,表观气速为0.08,0.28和0.56 m/s三个条件进行数值模拟得到的颗粒体积分数沿反应器轴向的分布情况和瞬时云图。

由图7可知,当表观气速为0.08 m/s时,密相床层顶部界面清晰,且稀相区几乎没有催化剂存在,气泡在分布板形成后,在上升过程中不断长大,此为典型鼓泡流态化。而当表观气速为0.56 m/s的高气速时,图7(a)显示床层沿轴向从密相逐渐过渡到稀相,图7(b)显示床层界面虽然存在,但是稀相区空域有大量颗粒存在使得床层界面比鼓泡流态化模糊的多,且床层气泡破碎加剧、膨胀程度和空隙率明显升高,此为典型的湍动流化态[7,30-31]。而0.28 m/s的结果为从鼓泡床到湍动床的过渡状态。

图7 不同表观气速下颗粒体积分数轴向分布与瞬时云图

Fig.7 Catalyst axial partide volume fraction distribution and nephogram with different superficial velocity

图8 不同表观气速下颗粒体积分数和速度的径向分布

Fig.8 Radial distribution of catalyst particle volume fraction and velocity with different height

文献表明操作压力增加会引起流型转变速度Uc下降,提前进入湍动流化态[7]。在3.0 MPa条件下,0.26 m/s左右的流型转变速度也低于之前常压条件下0.45 m/s的结果[19]。工业化费托合成反应和催化剂还原反应都是在一定压力下进行的[32-33],据此研究结果,在工程实践当中可适当加大操作压力,提高单位设备容积生产强度的同时使湍动流化区提前到达,改善流化质量[7]。

模型同时对不同表观气速、不同床层高度的颗粒体积分数和颗粒速度的径向分布进行了模拟,结果如图8所示。由图8(a)可知,在不同表观气速条件下,反应器床层3个高度界面径向的颗粒体积分数都存在明显的“环-核结构”,即颗粒体积分数中间稀、边壁浓;由图8(b)可知,中心区颗粒受气体曳力作用速度主体向上,壁面区颗粒受重力的作用向下运动,且随着气速的增加,径向的不对称性也随之增加。

2.3 操作温度对床层气固分布的影响

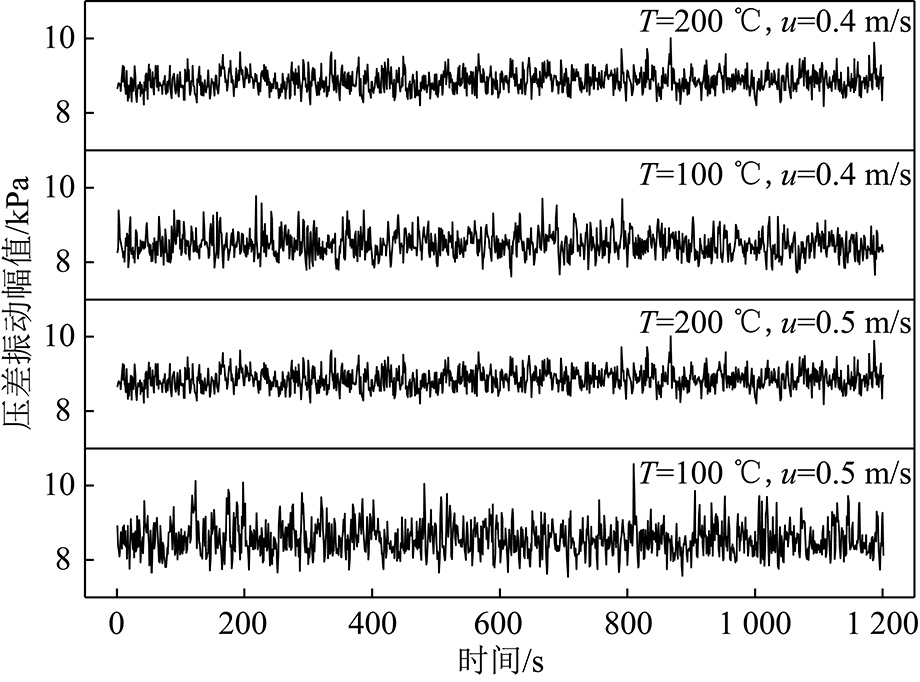

图9为3.0 MPa、2个表观气速条件下,温度(T)变化对反应床层总压差脉动幅值的影响。由图9可知,在0.4 m/s和0.5 m/s两个表观气速条件下,随着操作温度增加反应器床层总压差脉动幅值变小。这是由于温度升高促使反应器床层内气泡变小导致[7,34]。

图9 不同温度条件下床层压差脉动幅值

Fig.9 Variation of bed pressure fluctuation with different temperature

图10为3.0 MPa、2个表观气速条件下,温度对床层轴向空隙率的影响结果和0.5m/s条件下颗粒体积分数轴向分布的模拟结果。

由图10可知,在为0.4~0.5 m/s的表观气速下,200 ℃范围内床层各段空隙率和颗粒体积分数分布比较接近。由此可知,温度条件对反应器内催化剂床层宏观的流态化影响并不显著。

图11为表观气速0.5 m/s、温度为100 ℃和200 ℃时,颗粒体积分数及颗粒速度的径向分布模拟结果。

图10 温度条件对床层空隙率和颗粒体积分数的影响

Fig.10 Axial distribution of voidage and particle volume fraction with different temperature

图11 不同温度条件下颗粒体积分数和速度的径向分布

Fig.11 Radial distribution of catalyst particle volume fraction and velocity with different temperature

由图11可知,在100~200 ℃的操作温度内,颗粒体积分数和颗粒速度沿径向都呈“环-核结构”,其分布受温度影响并不显著。

3 结 论

(1)增加操作压力会降低流化床反应器床层压差脉动幅值。

(2)3.0 MPa条件下床层由鼓泡态转变为湍动态的速度为0.26 m/s左右;反应器内颗粒体积分数沿轴向成中心稀、边壁浓的“环-核结构”;颗粒速度沿轴向呈中心上行、边壁下行的流动趋势。

(3)升高温度会降低床层压差脉动幅值,但对颗粒体积分数和颗粒速度的宏观分布影响并不显著。

[1] 张姗.世界及中国油气发展形势初步分析[J].中国能源,2019,41(3) :29-32.

ZHANG Shan.Preliminary analysis of oil and gas development in the world and China[J].Energy of China,2019,41(3):29-32.

[2] 李强,叶松寿,崔德春,等.合成气完全甲烷化催化剂的公斤级放大制备及催化反应工艺研究[J].高校化学工程学报,2017,31(1):90-96.

LI Qiang,YE Songshou,CUI Dechun,et al.Kilogram scale-up preparation of catalysts and its reaction process in syngas methanation[J].Journal of Chemical Engineering of Chinese Universities,2017,31(1):90-96.

[3] 李文英,李旺,冯杰.褐煤直接液化过程中存在的问题与思考[J].煤炭学报,2020,45(1):414-423.

LI Wenying,LI Wang,FENG Jie.An overview on issues for lignite direct liquefaction[J].Journal of China Coal Society,2020,45(1):414-423.

[4] 毛学锋.煤基液体产物中酚类化合物的组成研究[J].煤炭学报,2018,43(1):265-271.

MAO Xuefeng.Distribution and composition of phenolic compounds in coal-based liquid production[J].Journal of China Coal Society,2018,43(1):265-271.

5] 吴艳,赵鹏,毛学锋.煤液化条件下铁系催化剂的相变[J].煤炭学报,2018,43(5):1448-1454.

WU Yan,ZHAO Peng,MAO Xuefeng.Phase transformation of iron-based catalyst at coal liquefaction[J].Journal of China Coal Society,2018,43(5):1448-1454.

[6] YAN Bingfeng,WANG Guangyao.Mechanisms and characteristics of mesocarbon microbeads prepared by co-carbonization of coal tar pitch and direct coal liquefaction residue[J].International Journal of Coal Science & Technology,2019,6(4):633-642.

[7] 金涌,祝京辉,汪展文,等.流态化工程原理[M].北京:清华大学出版社,2001.

[8] 相宏伟,杨勇,李永旺.煤炭间接液化:从基础到工业化[J].中国科学:化学,2014,44(12):1876-1892.

XIANG Hongwei,YANG Yong,LI Yongwang.Indirect coal-to-liquids technology from fundamental research to commercialization[J].Scientia Sinica Chimica,2014,44(12):1876-1892.

[9] 孙启文.煤炭间接液化[M].北京:化学工业出版社,2012.

[10] 周从文,林泉.费托合成技术应用现状与进展[J].神华科技,2010,8(4):93-96.

ZHOU Congwen,LIN Quan.The state of the art review of Fischer- Tropsch synthesis technology[J].Shenhua Science and Technology,2010,8(4):93-96.

[11] 孙延林,曾玺,王芳,等.低阶碎煤流化床两段气化中试试验[J].煤炭学报,2017,42(5) :1297-1303.

SUN Yanlin,ZENG Xi,WANG Fang,et al.Pilot test of low-rank crushed coal gasification in two-stage fluidized bed reactor[J].Journal of China Coal Society,2017,42(5) :1297-1303

12] SHAH M T,UTIKAR R P,PAREEK V K.CFD study:Effect of pulsating flow on gas-solid hydrodynamics in FCC riser[J].Particuology,2017,31(2):25-34.

[13] 曹晓阳,周发戚,陈勇,等.循环流化床颗粒输送斜管的压力脉动特性[J].石油学报(石油加工),2016,32(5):913-920.

CAO Xiaoyang,ZHOU Faqi,CHEN Yong,et al.Characteristics of pressure fluctuations in the particle-transport inclined standpipe of a circulating fluidized bed[J].Acta Petrolei Sinica (Petroleum Processing Section),2016,32(5):913-920.

[14] 谢朝钢,魏晓丽,龚剑洪,等.催化裂化反应机理研究进展及实践应用[J].石油学报(石油加工),2017,33(2):189-197.

XIE Chaogang,WEI Xiaoli,GONG Jianhong,et al.Process on chemistry of catalytic cracking reaction and its practice[J].Acta Petrolei Sinica (Petroleum Processing Section),2017,33(2):189-197.

[15] 罗琴,张玉黎,赵银峰,等.ECT测量A类颗粒初始流化特性[J].中南大学学报(自然科学版),2016,47(11):3916-3921.

LUO Qin,ZHANG Yuli,ZHAO Yinfeng,et al.Measuring minimum fluidization velocity of Geldart particles by use of electrical capacitance tomography[J].Journal of Central South University (Science and Technology),2016,47(11):3916-3921.

[16] 刘文东,张锴,毕继诚.FCC颗粒散式或聚式流态化特性的CFD模拟[J].石油化工高等学校学报,2007,20(2):43-46.

LIU Wendong,ZHANG Kai,BI Jicheng.CFD simulation on homogeneous or aggregative fluidization of FCC particles[J].Journal of Petrochemical Universities,2007,20(2):43-46.

[17] 梁斌,冯强,白浩隆,等.煤泥干粉在流化床中燃烧特性的实验研究[J].煤炭学报,2018,43(S2):560-567.

LIANG Bin,FENG Qiang,BAI Haolong,et al.Combustion characteristics of dry coal slime powders in a fluidized bed[J].Journal of China Coal Society,2018,43(S2):560-567.

[18] 于杰,董玉平,常加富,等.玉米秸秆循环流化床气化中试试验[J].化工进展,2018,37(8):2970-2975.

YU Jie,DONG Yuping,CHANG Jiafu,et al.Pilot experiment of gasification of corn straw in circulating fluidized bed[J].Chemical Industry and Engineering Progress,2018,37(8):2970-2975.

[19] 冯留海,冯钰琦,赵杰,等.气固流化床内费托铁基催化剂的流化特性[J].过程工程学报,2020,20(3):302-307.

FENG Liuhan,FENG Yuqi,ZHAO Jie,et al.Flow behaviors of FT catalyst in gas-solid fluidized bed[J].The Chinese Journal of Process Engineering,2020,20(3):302-307.

>[20] 刘得金,李洪钟,李连轩,等.流态化过渡状态描述[J].化工学报,1994,45(3):334-341.

LIU Dejin,LI Hongzhong,LI Lianxuan,et al.Description of transitional fluidization patterns[J].Journal of Chemical Industry and Engineering (China),1994,45(3):334-341.

[21] FENG Rongtao,LI Junguo,CHEN Zhonghu,et al.Influence of particle size distribution on minimum fluidization velocity and bed expansion at elevated pressure[J].Powder Technology,2017,320:27-36.

[22] ZHU J,QI M,BARGHI S.Identification of the flow structures and regime transition in gas-solid fluidized beds through moment analysis[J].Aiche Journal,2013,59(5):1479-1490.

[23] LIOP M F,CASAL J,ARNALDOS J.Expansion of gas-solid fluidized beds at pressure and high temperature[J].Powder Technology,2000,107(3):212-225.

[24] BAI H T,ELLIS N,ABBA I A,et al.A state-of-the-art review of gas-solid turbulent fluidization[J].Chemical Engineering Science,Pergamon,2000,55(21):4789-4825.

[25] 马树辉,王若瑾,王德武,等.Geldart A类颗粒节涌床气固流动特性的实验及模拟[J].过程工程学报,2019,19(5):967-974.

MA Shuhui,WANG Ruojin,WANG Dewu,et al.Experiment and simulation of gas-solid flow characteristics of Geldart A particles[J].The Chinese Journal of Process Engineering,2019,19(5):967-974.

26] 佟颖,AHMAD Nouman,鲁波娜,等.基于EMMS 介尺度模型的双分散鼓泡流化床的模拟[J].化工学报,2019,70(5):1682-1692.

TONG Ying,AHMAD Nouman,LU Bona,et al.Numerical investigation of bubbling fluidized bed with binary particle mixture using EMMS mesoscale drag model[J].Journal of Chemical Industry and Engineering (China),2019,70(5):1682-1692.

[27] 戴群特,时凯,祁海鹰.基于介尺度特性分析的流态化过程数值方法[J].煤炭学报,2016,41(10):2508-2813.

AI Qunte,SHI Kai,QI Haiying.Research progress of simulation methods of fluidization process in CFB based on meso-scale characteristics analysis[J].Journal of China Coal Society,2016,41(10):2508-2513.

[28] HONG K,SHI Z,WANG W,et al.A structure-dependent multi-fluid model (SFM) for heterogeneous gas-solid flow[J].Chemical Engineering Science,2013,99:191-202.

[29] SHI Z,WANG W,LI J.A bubble-based EMMS model for gas-solid bubbling fluidization[J].Chemical Engineering Science,2011,66(22):5541-5555.

[30] 陈卫,任瑛.流态化与物质相变的相似性[J].化工学报,2019,70(1):1-9.

CHEN Wei,REN Ying.Similarity between fluidization and phase transition[J].Journal of Chemical Industry and Engineering (China),2019,70(1):1-9.

[31] 欧阳洁,李静海,孙国刚,等.气固流态化动态特征的模拟[J].应用基础与工程科学学报,2002,10(4):338-346.

OUYANG Jie,LI Jinghai,SUN Guogang,et al.Simulation of dynamic characteristics for gas-solid fluidization[J].Journal of Basic Science and Engineering,2002,10(4):338-346.

[32] HAO Q L.Effect of reduction temperature and duration on iron-based catalyst for slurry phase Fischer-Tropsch synthesis[J].Journal of Fuel Chemistry and Technology,2005,33(5):590-596.

[33] POUR A N,HOUSAINDDOKHT M R,TAYYARI S F,et al.Deactivation studies of nano-structured iron catalyst in Fischer-Tropsch synthesis[J].Journal of Energy Chemistry,2010,19(3):333-340.

[34] 马吉亮,刘道银,梁财,等.黏性 Geldart B类颗粒流化特性实验研究[J].工程热物理学报,2017,38(8):1702-1706.

MA Jiliang,LIU Daoyin,LIANG Cai,et al.Experimental study on the fluidization dynamics of cohesive Geldart B particles[J].Journal of Engineering Thermophysics,2017,38(8):1702-1706.

佟瑞利(1982—),男,河北怀来人,工程师,博士。Tel:010-57337343,E-mail:ruili.tong@chnenergy.com.cn

佟瑞利(1982—),男,河北怀来人,工程师,博士。Tel:010-57337343,E-mail:ruili.tong@chnenergy.com.cn