煤层气含量是表征煤储层特征的关键参数之一,是煤层气资源勘探开发和煤矿瓦斯灾害危险程度评价及治理工程设计的重要依据[1-5]。近年来,越来越多的国内外煤层气勘探开发[6-7]和煤矿开采实践活动[8-9]均显示,煤与煤层气勘探中测得的煤层气含量低于煤储层实际气含量。煤与煤层气勘探过程中普遍采用开放式岩芯管采取煤芯,煤芯样品在孔内提升和地面暴露过程中因煤基质表面压力降低而解吸逸散掉大量气体[10-11]。由煤层气含量测定方法[12]煤芯样品在孔内提升和地面暴露过程中逸散丢失的气体是采用估算的方法获得的。根据理论分析和大量的室内模拟试验结果表明,造成煤层气含量测值偏低的根本原因就是煤层气损失量估算偏低所致[13-16]。提高煤层气含量测试结果最为直接有效的途径就是采用密闭取心技术,将煤芯样品在孔底密封,避免孔内提升和地面暴露过程中气体逸散丢失,消除损失量估算不准带来的误差。

密闭取心在石油、天然气和天然气水合物等领域已开展相关研究。国外密闭取心设备主要有国际深海钻探计划DSDP-PCB保压取心器[17]、国际大洋钻探计划ODP-PCS保压取心器[18]、日本和美国共同研制的PTCS保温保压取心器[19]和欧盟研制的HYACE天然气水合物高压密闭取心器[20-21]等。我国大庆油田自20世纪60年代开始密闭取心技术研究及探索工作,先后研制了BYM-Ⅰ型、BYM-Ⅱ型和BYM-Ⅲ型密闭保压取心器[22]。贺涛[23]设计了保温、保压、保形、绳索打捞等功能为一体的天然气水合物取心钻具,郭威等[24]在研究孔底冷冻取样方法的基础上设计试制了孔底冷冻保温保压取心器。王海亮等[25]设计并试制了FCS-108型,张永勤等[26]设计并试制了适用于冻土天然气水合物保压取心器,杨立文等[27]设计并试制了GW194-70BB型保温保压密闭取心器。任红等[28]采用三维设计软件设计了绳索式天然气水合物保温保压取心工具,并在我国南海LW3区块的2口井开展了13回次的取样。针对煤矿井下煤层瓦斯含量测定,齐黎明等[29]开展了煤层密闭取心试验及应用研究,中煤科工集团西安研究院有限公司“十一五”“十二五”“十三五”期间在国家科技重大专项资助下先后开展了煤矿井下和地面煤层气(瓦斯)含量测定用密闭取心技术研究工作[30-33]。

油气储层一般埋藏深、温度高、压力大,其保压密闭取心设备尺寸较大、工艺复杂、设备昂贵、使用成本较高。煤储层一般具有埋藏浅、温度低、压力小和井型小等特点,另外,煤体强度低、结构易破碎,煤层密闭采取难度更大。因此,笔者依托“十三五”国家油气重大专项任务“地面钻井煤层密闭取心气含量测试技术及装置”,开展了地面井煤层气含量测定用的密闭取心器及其取心工艺技术研究。

1 煤层气含量精准测试构想

按照现行煤层气含量测定标准,煤层气含量总体上由损失气含量、解吸气含量和残余气含量3部分构成。解吸气含量和残余气含量是煤样装罐密封后由试验实测所得,测试结果可靠;损失气含量是煤样在孔内提升和地面暴露中因煤样裸露煤基质表面压力降低而解吸逸散的气体量,是根据煤样装罐后早期解吸数据采用![]() 法估算所得,因损失量估算模型假设条件的理想化和估算数据采集的人为性,导致损失量估算值与实际逸散量之间存在差异。为了避免煤样采取过程发生气体解吸逸散丢失现象,实现煤层气含量精准测试,借鉴油气保压密闭取心的工作思想,设计一种适合于煤储层特点的地面井煤层密闭取心设备及取心方法。在孔底待煤样进入到取心设备后将其密闭,防止煤样在孔内提升和地面暴露过程中因压力降低导致气体解吸逸散丢失,规避煤层气含量测试过程中的损失气量估算,实现煤样气量均由实验实测所得。最终将煤层气含量测试构成由3部分变成2部分,即煤层气含量由解吸气含量和残余气含量2部分构成。

法估算所得,因损失量估算模型假设条件的理想化和估算数据采集的人为性,导致损失量估算值与实际逸散量之间存在差异。为了避免煤样采取过程发生气体解吸逸散丢失现象,实现煤层气含量精准测试,借鉴油气保压密闭取心的工作思想,设计一种适合于煤储层特点的地面井煤层密闭取心设备及取心方法。在孔底待煤样进入到取心设备后将其密闭,防止煤样在孔内提升和地面暴露过程中因压力降低导致气体解吸逸散丢失,规避煤层气含量测试过程中的损失气量估算,实现煤样气量均由实验实测所得。最终将煤层气含量测试构成由3部分变成2部分,即煤层气含量由解吸气含量和残余气含量2部分构成。

2 煤层气密闭取心设备设计及试制

2.1 密闭取心器设计与试制

针对煤层易受钻具转动而产生摩擦和振动,导致煤体原有特征和完整性受机械作用而破坏,影响煤芯采取效果。煤层气密闭取心器设计采用“三筒单动”结构,即外筒、内筒和液压传递筒,取心钻进过程中外筒随钻杆同步转动,而内筒和液压筒相对不动。外筒上端与钻杆相连、下端与取心钻头连接,外筒传递钻压和扭矩。内筒是煤芯和解吸气的存储容器,容积大小满足煤层气含量测定煤样量采取的需要;内筒上下端均与球阀相连,对煤芯样品进行密封保压;取心内筒上端球阀外侧安装一个解吸阀门,便于煤芯提至地面后进行解吸气的测量,实现取心与气含量测定一体化。液压推动筒传递液压动力,推动内筒上下端球阀关闭,其上端由销钉与悬挂总承相连。密闭取心器下部是取心钻头,在钻压和扭矩作用下钻头壁对煤层进行切削,以形成柱状煤芯进入到取心内筒。地面井密闭取心器结构设计如图1所示。

依据设计试制了地面井煤层气密闭取心器,密闭取心器外筒总长2 150 mm,直径120 mm,通过转换接头能与不同规格钻杆相连,能满足钻孔直径130 mm以上的煤层气(瓦斯)参数井或开发井中适用。取心内筒长1 200 mm,直径38 mm,积1 360 mL,取心内筒下端密闭球阀直径38 mm,采取煤(岩)芯直径可达38 mm,满足煤层气含量测定煤样质量要求。

1—钻杆转接头;2—悬挂总成(2-1取心器固定卡键、2-2内筒悬挂销钉);3—投球系统;4—液压动力机构(4-1活塞总成,4-2推动轴承,

4-3动力销钉,4-4液压推动筒);5—上端密闭解吸系统(5-1解吸阀门端口、5-2单向阀、5-3上端密闭球阀);6—取心外筒;7—取心内筒;

8—高压割心密闭系统(8-1下球阀关闭连接管,8-2下球阀关闭套筒,8-3下端球阀,8-4下球阀限位套筒,8-5岩芯卡簧、

8-6下球阀关闭滑块);9—钻头系统(9-1外钻头,9-2内螺纹钻头);10—密封圈组件

图1 地面井煤层气含量测定密闭取心器结构组成

Fig.1 Composition of sealed coring device for determining coalbed gas content in the ground wells

2.2 密闭取心器密闭性能检测

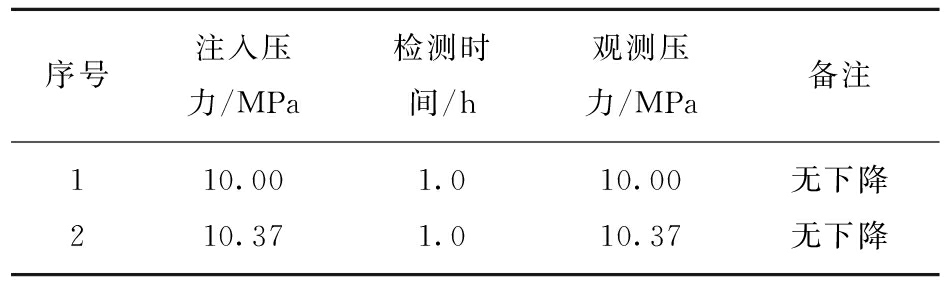

密闭取心器密闭检测试验主要利用高压泵向取心内筒注入一定压力的流体,当压力达到一定数值后切断高压补给源,并采用压力表和电子压力计两种方式同时检测取心内筒流体压力变化情况。先后共进行了2次注压和保压检测试验,检测结果见表1。两次注入流体压力分别为10 MPa和10.37 MPa,高压状态连续观测1 h,密闭取心内筒无水滴渗漏现象,2种方式压力监测值均显示注入的压力值无下降。检测试验结果表明该密闭取心器的密闭保压能力达到10 MPa以上,达到设计要求,能够满足煤层埋深1 000 m井的密闭取心需要。

表1 密闭取心器密闭性能检测结果

Table 1 Detection results of sealing performance for sealed coring device

序号注入压力/MPa检测时间/h观测压力/MPa备注110.001.010.00无下降210.371.010.37无下降

2.3 碎软煤层密闭取心钻头设计及试制

碎软煤层易破碎、水敏性强、胶结性差等特点,常规取心钻头因泥浆液的冲蚀和钻头壁的剥蚀等作用会导致煤芯采取率低或无法采到煤样。针对碎软煤层密闭取心提出了双径PDC密闭取心钻头,采用内、外径钻头组合形式,前端小径钻头钻进取心,后端大径钻进成孔,双径密闭取心钻头设计如图2所示。外钻头总体呈上宽下窄的锥形,导流面上设置4个切削翼,每个切削翼上布置1组切削齿和1组保径齿,每2个切削齿之间设置2个水眼,外钻头水眼向外偏离钻头体轴线,保证泥浆流冷却钻头和顺利排渣的同时,降低泥浆流对煤芯的冲刷作用。内钻头本体呈管状,圆管截面上均匀布置4个切削齿,内钻头与外钻头之间采用螺纹连接,针对煤体破坏程度不同的煤层可及时更换内径钻头。

取心回转钻进前,依靠钻具自重将小径取心钻头压入煤层中,超前形成“柱状”煤芯,煤层表面支撑着大径钻头端面,上下端密闭球阀均处于打开状态,如图3(a)所示。钻具回转取心钻进时,取心设备前端总是超前形成“柱状”煤芯,在钻具自重挤压和回转切削作用下,“柱状”煤芯不断进入取心内筒;同时,大径钻头也不断切削煤层,侧喷水眼喷出的泥浆液将大径钻头切削掉的煤(岩)屑携带走,形成钻孔井眼,如图3(b)所示。当取心钻进达到预定设计进尺后,投球封堵改变密闭取心装置水路,高压泥浆液推动密闭球阀关闭,完成碎软煤层的取样和密闭,如图3(c)所示。

1—钻头体;2—大经钻头;3—小径钻头;4—大经切削翼;5—钻头导流面;6—水眼;7—大经钻头切削齿;8—小径钻头切削齿;9—保径齿

图2 碎软煤层双径PDC密闭取心钻头设计

Fig.2 Design plan of the sealed double-diameter PDC coring bit for the broken and soft coal seams

1—超前切削头;2—煤层;3—常规切削头;4—超前“树心”;5—下端球阀;6—取心内筒;7—取心外筒;8—上端球阀

图3 碎软煤层双径PDC密闭取心钻进取心工作原理

Fig.3 Schematic diagram of working principle of sealed coring drilling with double diameter PDC bit for the broken and soft coal seams

3 煤层气含量测定密闭取心工艺技术

密闭取心钻进前,首先对密闭取心设备进行装配,将取心内筒上下端球阀置于开启状态。当钻进至预定煤层取心深度后,提出钻具连接密闭取心设备,并将密闭取心设备下到预定煤层深度,要确保小径钻头进入到碎软煤层中。更换低排量的泥浆泵,按照设计的钻压、转速和泥浆流量进行取心钻进;当取心钻进进尺达到设计值后,停泵停止钻进,向取心钻具内孔中投入钢球,钢球依靠自重坐落于密闭取心设备底座上,堵住密闭取心设备正常钻进的水路;根据煤层煤体破碎情况适当上提钻具(硬煤上提20~30 cm,碎软煤层上提5~10 cm)。再次开启泥浆泵向钻具中注入泥浆液,密切观察泥浆泵压力表值变化,当泥浆泵表压升高到一定数值(一般6 MPa以上)后出现明显快速下降,且孔口出现返浆现象,表明密闭取心设备水路畅通,密闭取心设备球阀已关闭。密闭取心具体操作工艺流程如图4所示。提钻取出密闭取心设备,初步检查设备的球阀关闭情况;拆卸密闭取心设备,取出装有煤样的密闭取心内筒,清洗掉附着在取心内筒外壁的泥浆液,放置水浴中检查其密闭性;判定取心内筒密闭完好后,将其与解吸仪直接相连,然后缓慢打开上端球阀进行煤样的解吸气量测试。现场解吸完成后,连同取心内筒和煤样一块送到实验室进行室内解吸气测试和残余气测定,密闭取心煤样的解吸气含量和残余气含量测定按照现行标准执行。

图4 地面井煤层气含量测定密闭取心工艺流程

Fig.4 Process of sealed coring for determining coalbed gas content in the ground wells

4 地面井密闭取心现场工程应用试验及结果分析

4.1 试验区煤层气地质概况

淮北芦岭矿区密闭取心试验煤层为二叠系下石盒子组8煤,煤的镜质体最大反射率为0.64%~1.01%。煤层厚度0.14~16.62 m,平均10.99 m,煤的坚固性系数(f值)为0.1~0.5,煤体结构主要为碎粒煤和糜棱煤。地质勘查阶段测得煤层气含量6.66~11.06 m3/t,平均8.85 m3/t;地面井煤层气开发中测得煤层气含量为5.73~6.76 m3/t,平均6.31 m3/t;煤矿生产实践揭露测得煤层瓦斯含量为7.91~12.01 m3/t,平均9.88 m3/t。芦岭煤矿为煤与瓦斯突出矿井,矿井绝对瓦斯涌出量100 m3/min,相对涌出量26.73 m3/t。

淮南潘三矿密闭取心试验煤层为二叠系上石盒子组13-1煤层,煤的镜质体最大反射率为0.69%~1.04%。煤层厚度0.94~8.83 m,平均3.73 m,煤的坚固性系数(f值)为0.30~0.70,平均0.52。煤层顶部、底部构造煤较为发育,煤体结构主要为碎粒煤和糜棱煤。地质勘查阶段测得煤层气含量为1.19~7.75 m3/t,平均5.25 m3/t;矿井生产期间测得煤层气含量为4.78~7.80 m3/t,平均6.66 m3/t。潘三矿为煤与瓦斯突出矿井,矿井绝对瓦斯涌出量达151.64 m3/min,相对瓦斯涌出量达18.28 m3/t。

4.2 地面井密闭取心工程应用试验

利用研制的地面井密闭取心设备,分别在淮南、淮北2个典型高突矿井进行地面密闭取心工程应用试验。设计每口井同一煤层中均采用密闭取心和常规取心2种方式采取煤芯进行气含量测定,根据煤层煤体结构特点和密闭取心设备工作要求,制定了密闭取心技术参数。选用BW-250型泥浆泵作为推动密闭球阀关闭的动力源,取心钻进及设备孔内提升采用TSJ-2000型钻机。每口井取心工程量和密闭取心技术及取心试验结果见表2。

由表2可知,2口井的密闭取心井深度分别为672.5~679.2和736.4~740.7 m。密闭球阀关闭受煤芯软硬程度、球阀部位煤芯密实程度和是否采到煤芯等因素的影响,试验中球阀关闭压力值为6~10 MPa。2口井设计7个回次密闭取心,6次密闭球阀成功关闭,在试验2井PSK-3回次中因煤层夹矸作用致球阀未完全关闭,将该次取心视为常规取心。试验1井LLMBQX-1回次因泵注流量严重超过了设计值达到106 L/min而未采取到煤芯外,其余回次取心钻进中的转速、钻压和泵注流量均控制在设计范围内,2口井密闭取心的煤芯采取率为62.73%~75.00%,均值70.21%。

4.3 密闭取心气含量测试结果分析

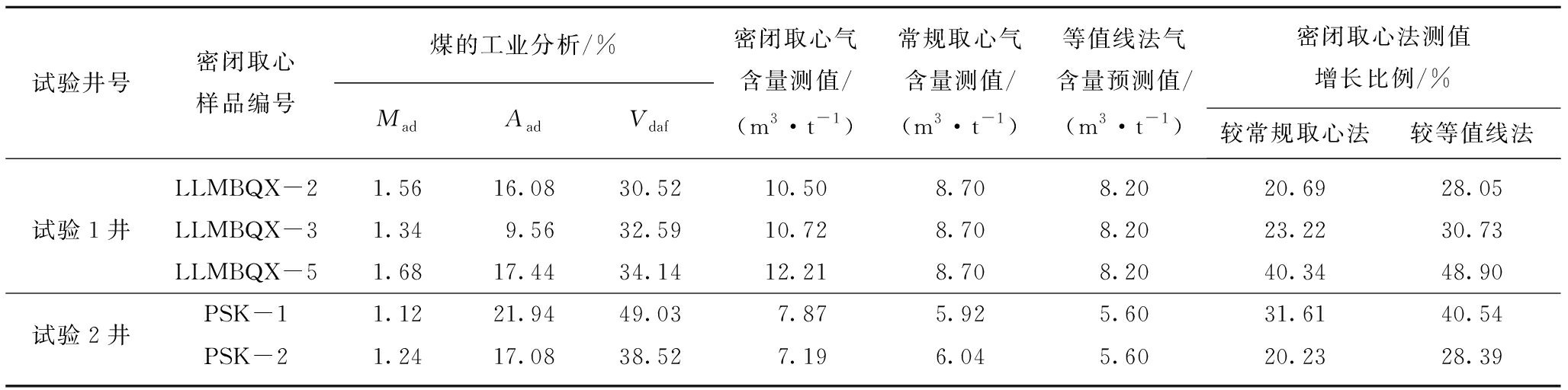

2口地面试验井共采集到试验样品8组,其中密闭试验样品5组,常规试验样品3组(含1组密闭失败样品,认其为常规试验样品)。便于不同勘查阶段测得的气含量数值比对,对本次采集到的试验样品气含量测试均按照AQ 1046-2007《地勘时期煤层瓦斯含量测定方法》执行;另外,利用试验井周围煤田地质勘查阶段测得的煤层气(瓦斯)含量(常规取心法)绘制该井周围气含量等值线,以预测试验井部位煤层的气含量值。2口井气含量预测等值线如图5所示。试验样品测试和等值线法预测的煤层气(瓦斯)含量结果见表3,便于数据的对比分析,表中煤层气含量基准均为干燥无灰基。

表2 地面井煤层气含量测定密闭取心技术参数及采取结果

Table 2 Technical parameters of sealed coring technology for the determination of the coalbed gas content in the ground wells

试验井号试验样品编号取样深度/m取心方式转速/(r·min-1)设计实际流量/(L·min-1)设计实际钻压/kN设计实际关闭压力/MPa煤芯采取率/%煤层气含量/(m3·t-1)LLMBQX-1672.5~673.5密闭50~807540~6010612~16136.00—LLMBQX-2673.6~674.8密闭50~807040~606012~1614~1510.074.1710.50试验1井LLMBQX-3674.8~675.9密闭50~805440~606012~16159.569.0910.72LLMBQX-4676.8~678.1常规50~805540~603512~1616—77.698.70LLMBQX-5678.1~679.2密闭50~806540~603512~16148.562.7312.21PSK-1736.4~737.0密闭50~807540~606012~1615~167.575.007.87PSK-2737.6~738.9密闭50~807540~605212~1614~168.570.067.19试验2井PSK-3738.9~739.9密闭50~806540~606012~1612~13密闭失败71.006.04PSK-4739.9~740.7常规50~807040~605212~1614~15—68.755.92

图5 等值线法预测2口地面试验井部位的煤层气含量(单位:m3/t)

Fig.5 Coalbed gas content of 2 ground wells,predicted by isoline method(unit:m3/t)

表3 地面井密闭取心与常规取心和等值线预测的煤层气含量

Table 3 Coalbed gas content from the sealed coring and conventional in the ground wells,predicted by the isoline method

试验井号密闭取心样品编号煤的工业分析/%MadAadVdaf密闭取心气含量测值/(m3·t-1)常规取心气含量测值/(m3·t-1)等值线法气含量预测值/(m3·t-1)密闭取心法测值增长比例/%较常规取心法较等值线法LLMBQX-21.5616.0830.5210.508.708.2020.6928.05试验1井LLMBQX-31.349.5632.5910.728.708.2023.2230.73LLMBQX-51.6817.4434.1412.218.708.2040.3448.90试验2井PSK-11.1221.9449.037.875.925.6031.6140.54PSK-21.2417.0838.527.196.045.6020.2328.39

由表3可知,试验1井3个密闭取心煤样测得气含量10.50~12.21 m3/t,均值11.14 m3/t,常规取心煤样测得气含量8.70 m3/t,等值线法预测该井部位煤层气含量8.20 m3/t;密闭取心法测得煤层气含量较常规取心法测值提高了20.69%~40.34%,均值28.08%;密闭取心法测得煤层气含量较等值线法预测值提高了28.05%~48.90%,均值35.89%。试验2井2个密闭取心煤样测得气含量7.19~7.87 m3/t,均值7.53 m3/t,2个常规取心法测得气含量5.92~6.04 m3/t,均值5.98 m3/t,等值线法预测该井部位煤层的气含量为5.60 m3/t;密闭取心法测得煤层气含量较常规取心测试结果提高了20.23%~31.61%,均值25.92%;密闭取心气含量较等值线法预测值提高了28.39%~40.54%,均值34.47%。

工程应用试验结果表明:① 研制的密闭取心设备能够满足于地面井煤层气含量测定的密闭采样,密闭取样避免了煤样孔内提升和地面暴露过程中大量气体的逸散丢失,测得的气含量值较常规取心法有了大幅提升;② 常规取心测得煤层气含量偏低是由于煤样暴露气体逸散丢失且损失量估算不准,密闭取心是实现煤层气含量精准测试的主要途径。

5 结 论

(1)提出了适合于煤储层特征的地面井煤层气含量测定密闭取心方法,设计并试制了“三筒单动、球阀密闭、取心筒与解吸罐一体化”地面井煤层气密闭取心设备;设备长2.15 m,外径120 mm,采取煤(岩)芯直径可达38 mm,密闭保压能力达10.37 MPa,满足煤层埋深超过1 000 m的地面井煤层气含量测定密闭取样。

(2)研制了前端小径钻心、后端大径钻井的双径PDC密闭取心钻头,减少了密闭取心钻进过程中泥浆液对碎软煤层的冲洗旋流作用,有效提高了碎软煤层的煤芯采取率。

(3)利用密闭取心设备在淮北芦岭煤矿和淮南潘三煤矿的碎软煤层中开展了地面井煤层气含量测定密闭取心工程应用试验,测试结果表明密闭取心方法获得的煤层气含量比常规取心法获得的煤层气含量高20.23%~40.34%,均值27.22%。

[1] 张群,冯三利,杨锡禄.试论我国煤层气的基本储层特点及开发策略[J].煤炭学报,2001,26(3):230-235.

ZHANG Qun,FENG Sanli,YANG Xilu.Basic reservoir characteristics and development strategy of coalbed methane resource in China[J].Journal of China Coal Society,2001,26(3):230-235.

[2] 胡千庭,邹银辉,文光才,等.瓦斯含量法预测突出危险新技术[J].煤炭学报,2007,32(3):276-280.

HU Qianting,ZOU Yinhui,WEN Guangcai,et al.New technology of outburst danger pred iction by gas content[J].Journal of China Coal Society,2007,32(3):276-280.

[3] 孙四清.煤矿区煤层气抽采效果检测指标及评价[J].煤矿安全,2017,48(5):173-176.

SUN Siqing.Detection indexes of coalbed methane drainage effect and evaluation method in coal mine area safety in coal mines[J].Safety in Coal Mines,2017,48(5):173-176.

[4] CHENG Yuanping,JIANG Haina,ZHANG Xiaolei,et al.Effects of coal rank on physicochemical properties of coal and on methane adsorption[J].International Journal of Coal Science & Technology 2017,4(2):129-146.

[5] ZHAO Bo,WEN Guangcai,SUN Haitao,et al.Similarity criteria and coal-like material in coal and gas outburst physical simulation[J].International Journal of Coal Science & Technology,2018,5(2):167-178.

[6] NELSON C R.Effect of vertical degasification wells on coal seam gas content reduction at the Oak Grove Field,Black Warrior Basin,Alabama[A].Proceedings of the 2004 International Coalbed Methane Symposium[C].Tuscaloosa:The University of Alabama,2004.

[7] 煤炭科学研究总院西安研究院.焦坪矿区侏罗系煤层气开发试验研究综合研究报告[R].西安:煤炭科学研究总院西安研究院,2009.

Xi’an Branch China Coal Research Institute.Comprehensive Research Report on Jurassic coalbed methane development in Jiaoping mining area[R].Xi’an:Xi’an Branch of China Coal Research Institute,2009.

[8] 张子敏,张玉贵.大平煤矿特大型煤与瓦斯突出瓦斯地质分析[J].煤炭学报,2005,30(2):137-140.

ZHANG Zimin,ZHANG Yugui.Investigation into coal-gas outburst occurred in Daping Coalmine,by using theories of gas-geology[J].Journal of China Coal Society,2005,30(2):137-140.

[9] 秦勇.中国煤层气产业化面临的形势与挑战(Ⅱ):关键科学技术问题[J].天然气工业,2006,26:4-8.

QIN Yong.Situation and challenges for coalbed methane industrialization in China(Ⅱ)—Key scientific and technological problems[J].Natural Gas Industry,2006,26:4-8.

[10] 孟艳军,汤达祯,许浩,等.煤层气解吸阶段划分方法及其意义[J].石油勘探与开发,2014,41(5):612-617.

MENG Yanjun,TANG Dazhen,XU Hao,et al.Division of coalbed methane desorption stages and its significance[J].Petroleum Exploration and Development,2014,41(5):612-617.

[11] 杨兆彪,秦勇,王兆丰,等.钻井液条件下煤芯煤层气解吸扩散行为及其影响[J].中国矿业大学学报,2009,38(5):624-628.

YANG Zhaobiao,QIN Yong,WANG Zhaofeng,et al.Behaviors and influencing factors of desorption-diffusion of methane from coal core under drilling fluid medium[J].Journal of China University of Mining & Technology,2009,38(5):624-628.

[12] 中华人民共和国国家质量监督检验检疫总局,中国国家标准化管理委员会.煤层气含量测定方法:GB/T 19559—2008[S].北京:煤炭工业出版社,2008.

[13] 张群,范章群.煤层气损失气含量模拟试验及结果分析[J].煤炭学报,2009,34(12):1649-1654.

ZHANG Qun,FAN Zhangqun.Simulation experiment and result analysis on lostgas content of coalbed methane[J].Journal of China Coal Society,2009,34(12):1649-1654.

[14] 范章群.煤层气损失气含量模拟试验及估算模型探讨[D].北京:煤炭科学研究总院,2009.

FAN Zhangqun.Study on simulation experiment and estimate method for coalbed methane lost gas content[D].Beijing:China Coal Research Institute,2009.

[15] 杨兆彪,秦勇,王兆丰,等.钻井液条件下煤芯层气解吸-扩散模型及逸量求取[J].中国科学:地球科学,2010,40(2):171-177.

YANG Zhaobiao,QIN Yong,WANG Zhaofeng,et al.Desorption-diffusion model and lost gas quantity estimation of coalbed methane from coal core under drilling fluid medium[J].Science China:Earth Science,2010,40(2):171-177.

[16] KISSELL F N,MCCULLOCH C M,ELDER C H.The direct method of determining methane content of coalbeds for ventilation design[R].U.S.Bureau of Mines Report of Investigation,R17767,1973.

[17] KVENVOLDEN K A,BARNARD L A,CAMERON D H.Pressure core barrel:Application to the study of gas hydrates,deep sea drilling project site 533,Leg76[R].Washington U.S.:Government Printing Office,1983.

[18] PETTIGREW T L.Design and operation of a wire line pressure core sample(PCS)[R].Galveston:Texas A&M University,1992.

[19] MASAYUKI K,SATORU U,MASATO Y.Pressure temperature core sampler(PTCS)[J].Journal of the Japanese Association for Petroleum Technology,2006,71(1):139-147.

[20] FRANK R R,TIM F,PETER S,et al.In-situ sampling and characterization of naturally occurring marine methane hydrate:ODP Leg 204[A].Hydrate Ridge,DOE/NETL Project Review Meeting[C].Winchester,2003.

[21] SCHULTHEISS P J,FRANCIS T J G,HOLLAND M,et al.Pressure coring,logging and subsampling with the HYACINTH system[J].Geological Society,London,Special Publications,2006,267(1):151-163.

[22] 张洪君,刘春来,王晓舟,等.深层保压密闭取心技术在徐深12井的应用[J].石油钻采工艺,2007,29(4),110-114.

ZHANG Hongjun,LIU Chunlai,WANG Xiaozhou,et al.Application of deep pressure confined coring technology in Xushen 12 wells[J].Oil Drilling & Production Technology,2007,29(4):110-114.

[23] 贺涛.天然气水合物保温保压绳索取心钻具设计[D].北京:中国地质大学(北京),2011.

HE Tao.Design of wire line pressure and temperature-preservation core tool for natural gas hydrates[D].Beijing:China University of Geosciences(Beijing),2011.

[24] 郭威.天然气水合物孔底冷冻取样方法的室内试验及传热数值模拟研究[D].长春:吉林大学,2007.

GUO Wei.Research on simulation of heat transfer and indoor experiment of freezing method for sampling gas hydrates[D].Changchun:Jilin University,2007.

[25] 王海亮.FCS-108型天然气水合物孔底冷冻取样器的研制及试验研究[D].长春:吉林大学,2009.

WANG Hailiang.Development and experimental investigation of freezing core sample of gas hydrates-FCS-108[D].Changchun:Jilin University,2009.

[26] 张永勤,祝有海.祁连山永久冻土带天然气水合物钻探工艺与应用[J].地质通报,2011,30(12):1904-1909.

ZHANG Yongqin,ZHU Youhai.Research and application of the natural gas hydrate drilling technique in Qilian Mountain permafrost[J].Geological Bulletin of China,2011,30(12):1904-1909.

[27] 杨立文,孙文涛,罗军,等.GWY194-70BB 型保温保压取心工具的研制和应用[J].石油钻采工艺,2014,36(5):58-61.

YANG Liwen,SUN Wentao,LUO Jun,et al.Study and application of GWY194-70BB heat and pressure preservation coring tool[J].Oil Drilling & Production Technology,2014,36(5):58-61.

[28] 任红,裴学良,吴仲华,等.天然气水合物保温保压取心工具研制及现场试验[J].石油钻探技术,2018,46(3):44-48.

REN Hong,PEI Xueliang,WU Zhonghua,et al.Development and field tests of pressure-temperature preservation coring tools for gas hydrate[J].Petroleum Drilling Techniques,2018,46(3):44-48.

[29] 齐黎明.卸压密闭煤层瓦斯含量测定技术研究[D].北京:中国地质大学(北京),2011.

QI Liming.Research on the measuring gas content technology of stress-releasing and sealed coal core[D].Beijing:China University of Geosciences(Beijing),2011.

[30] 张丁亮,黑磊,张培河,等.一种井下煤层密闭取心装置及使用方法[P].中国专利:ZL20101D101528,2013.

[31] 孙四清,张群,龙威成,等.煤矿井下长钻孔煤层瓦斯含量精准测试技术及装置[J].煤田地质与勘探,2019,47(4):1-5.

SUN Siqing,ZHANG Qun,LONG Weicheng,et al.Accruate test technology and device for coal seam gas content in long borehole in underground coal mines[J].Coal Geology & Exploration,2019,47(4):1-5.

[32] 孙四清,张群,张培河,等.地面钻井煤层气、岩层气含量测试密闭取心装置[P].中国专利:ZL201410739874.9,2018.

[33] 孙四清.煤层气含量地面井密闭取心与快速测定技术研究[D].北京:煤炭科学研究总院,2018.

SUN Siqing.Study on surface well sealed coring and fast measurement for coal seam gas content[D].Beijing:China Coal Research Institute,2018.