移动阅读

ZHANG Yujie,GUO Hongguang,LI Zhigang,et al.Promoted microbial degradation of lignite by supercritical CO2 extraction to enhance coalbed methane production[J].Journal of China Coal Society,2021,46(10):3278-3285.

SCOTT在1999年提出通过将厌氧微生物种群及其所需营养物质注入煤层[1],利用微生物能够降解煤产甲烷的特性来实现煤层气的增产,即微生物增产煤层气(MECBM)[2-3]。国内外已对生物成气过程所涉及的厌氧发酵理论形成初步认识[4-5]。然而,煤结构较为复杂,含有大量微生物难以降解和利用的有机物,导致生物利用度较低[6]。

目前,多种预处理手段被用于提高煤中有机物的生物利用度,以优化微生物增产煤层气技术[7-8]。数值模拟显示水力压裂可通过改善煤层渗透性、增强微生物在煤层中的扩散,提高生物甲烷产量达500%[9]。H2O2以其强氧化性、产物绿色等优点被广泛用于溶解煤以提高煤的生物利用度,并表现出较好甲烷增产效果[10]。此外,白腐真菌预处理也被证明能够有效改变煤的有机结构,从而促进生物对煤的降解[11]。

多年来,超临界CO2(ScCO2)萃取技术因其环保、萃取物纯度高等优势而被广泛用于混合物中活性化合物的提取[12]。已有研究显示,ScCO2也能够萃取煤中脂肪类和芳香类等有机成分[13-14],并且萃取过程中所产生的溶胀作用和非共价键破坏会导致小分子有机物从煤的大分子结构中分离出来[15],从而增加微生物可利用有机物的总量。此外,ScCO2作用下,煤的孔隙连通性得到改善[16]。与其他预处理技术相比,ScCO2已成功应用于煤层气增产(ScCO2-ECBM),这进一步增加了ScCO2预处理提高生物甲烷产生的可行性。由此,笔者以褐煤为研究对象,就相关问题开展了模拟实验研究。

实验用煤样为内蒙古宝日希勒褐煤,煤样采出后密封保存运回实验室。在实验室将煤样破碎研磨至0.18~0.25 mm(60~80目),在干燥箱中105 ℃烘干至恒重,然后真空密封包装放置在防潮箱中保存。原煤工业分析按照国家标准GB/T 212—2008进行(表1)。实验所用菌群富集自沁水盆地煤层气井产出水,该菌群能够降解煤并产生甲烷,最佳生长温度为 35 ℃,生长周期为21 d[17]。

表1 褐煤基础信息

Table 1 Basic information of lignite

煤样地质条件地质年代煤层工业分析/%MadAdVdafFCd原煤白垩纪下统123.5612.6546.0747.11

使用ScCO2萃取装置对煤样进行萃取。为了研究温度和压力条件对褐煤产生甲烷的影响,选取3种温度(40,60,80 ℃)和3种压力(10,15,20 MPa)条件进行萃取正交实验。每次实验萃取100 g煤样,萃取时间为4 h。萃取结束后,将萃余煤取出并封存,以备后续实验使用。使用色谱级二氯甲烷(DCM)收集萃取物,用于GC-MS分析,并对萃取率进行计算[18]。

实验所用培养基包括基础培养基、微量元素溶液、维生素溶液、半胱氨酸-硫化钠溶液,各营养液具体配比同文献[19]。

煤样厌氧降解实验步骤:以煤为惟一碳源,称取1 g煤粉加入厌氧瓶,一式3份。以不添加煤为空白组。在厌氧操作箱内,在厌氧瓶中加入23 mL灭菌水,3 mL菌液,3 mL基础培养基,0.15 mL维生素,0.15 mL微量元素,0.6 mL半胱氨酸-硫化钠溶液。35 ℃恒温培养。

萃取物厌氧降解实验步骤:以萃取物为惟一碳源,抽取0.5 mL萃取物加入10 mL厌氧管,一式3份,并通过氮吹除去多余的CH2Cl2。以添加不添加萃取物为空白组。在厌氧操作箱内,在厌氧管中加入2.3 mL灭菌水,0.3 mL菌液,0.3 mL基础培养基,0.015 mL维生素,0.015 mL微量元素,0.06 mL半胱氨酸-硫化钠溶液。35 ℃恒温培养。

利用气相色谱仪(GC112A)在第0,3,7,14,21天检测厌氧瓶和厌氧管顶部空间中的甲烷浓度。

选择0.1 MPa和5.0 MPa压力并结合萃余煤厌氧降解实验中所确定的最佳温度,使CO2处于气态。选择20 ℃,结合萃余煤厌氧降解实验中所确定的最佳压力,使CO2处于液态。操作流程与ScCO2萃取实验相同。实验结束后,对非超临界CO2处理残煤进行封存,用于生物降解实验。

用色谱级DCM溶剂萃取原煤和ScCO2萃余煤。称量10 g煤样放入150 mL烧杯,加入100 mL的DCM,以500 r/min转速磁力搅拌4 h。搅拌后所得混合物采用0.7 μm的滤膜进行抽滤。残煤在105 ℃条件下烘干后,密封保存,用于厌氧降解实验;过滤所得萃取液用于GC-MS分析。

在萃取液中加入足量无水硫酸钠,4 ℃放置12 h。上清液经旋蒸和氮吹,浓缩至2 mL。采用Agilent 7890B-5977B气相色谱质谱联用仪上分析萃取物化学成分。用99.999%的氦气作为载气,载气流速30 mL/min。升温程序为:初始温度60 ℃,保持3 min,先以10 ℃/min的速率升至110 ℃,随后以4 ℃/min的速度升至240 ℃。通过自动和手动检索,将GC-MS中化合物与美国国家标准与技术研究院(NIST 08)数据库对比,进行鉴定。

低温液氮等温吸附实验采用美国迈克仪器公司ASAP2460型物理吸附仪。温度为-196 ℃,相对压力在0.01~0.99。通过p/p0 = 0.99的单点吸附测定孔容,根据DFT模型计算孔隙分布,BET 理论计算比表面积[20-21]。采用国际纯粹与应用化学联合会(IUPAC)提出的孔径划分方案[21]:微孔(<2 nm)、介孔(2~50 nm)和大孔(>50 nm)。

不同煤样间的甲烷生成曲线呈相同趋势(图1)。在3~7 d,甲烷产量上升迅速,在15 d左右几乎达到平衡(图1(a))。其中,原煤甲烷累计产量为132.91 μmol/g 煤,空白组甲烷产量几乎为0。不同温压条件处理后的萃余煤甲烷产量均比原煤有不同程度的增加(图1(b))。萃取温度为60 ℃和80 ℃时,萃取压力对于产气的影响不大。萃取温度为40 ℃时,甲烷产量随萃取压力变化波动较大,其中40 ℃-10 MPa下的甲烷产量最大,达245.46 μmol/g煤,比原煤增加了约84.68%。

图1 原煤及萃余煤的甲烷生成曲线及累积甲烷产量

Fig.1 Methane production curves and accumulated methane yields of raw coal and extracted coal

上述实验结果说明,ScCO2萃取能够促进微生物降解褐煤、提高生物甲烷产量。

对比煤的非超临界CO2处理实验,分析温度、压力以及ScCO2萃取对甲烷生成的影响。实验温度压力组合分别为40 ℃-5 MPa,40 ℃-0.1 MPa,20 ℃-10 MPa,分别使CO2处于气态和液态,对原煤进行处理。图2显示,非超临界CO2处理残煤的累积甲烷产量在137.34~160.15 μmol/g煤。与原煤相比,温度和压力对煤的生物降解产甲烷量影响较小。但非超临界CO2处理残煤的产甲烷量远低于ScCO2萃余煤甲烷产量。因此,ScCO2的独特性质是提高甲烷产量的关键因素。

图2 原煤、最佳产气条件ScCO2萃余煤及非超临界CO2 处理残煤的甲烷生成曲线及累积甲烷产量

Fig.2 Methane production curves and accumulated methane yields of raw coal,treated coals under optimal ScCO2, and non-supercritical conditions

2.3.1 萃取物成分分析

选取最佳产气条件40 ℃-10 MPa和最佳萃取条件80 ℃-20 MPa下的萃取物进行GC-MS分析。在40 ℃-10 MPa萃取物中检测到20种化合物,在80 ℃-20 MPa萃取物中检测到14种化合物(表2)。芳香族化合物是煤中的主要有机化合物,其含量在萃取物中最高。微生物能够将生物可利用的芳香族化合物进一步转化为脂肪族化合物,并逐渐将其降解为低分子量有机物,供产甲烷菌使用[22-23]。在40 ℃-10 MPa萃取物和80 ℃-20 MPa萃取物中均观察到邻苯二甲酸二辛酯(DEHP),属单环含氧芳香类化合物,分别占71.49%和49.74%。JONES等[24]基于前人研究绘制了生物甲烷产生树状图,指出在微生物的发酵作用下单环芳香类化合物可以进一步转化为微生物易于利用的脂肪类小分子化合物。同时,已有研究发现随着培养时间增长,含氧芳香化合物逐渐减少,含氧化合物是微生物降解的主要目标[25]。此外,样品中还检测到长链和中链烷烃,通常认为更容易被微生物利用[26]。因此,ScCO2从煤中萃取出的有机物可以被微生物降解,产生甲烷。

表2 40 ℃-10 MPa和80 ℃-20 MPa条件下褐煤的萃取物成分

Table 2 Composition of extracts from lignite under 40 ℃-10 MPa and 80 ℃-20 MPa

温压组合条件峰号化合物分子式匹配度相对含量/%40 ℃-10 MPa11-三十七烷醇C37H76O70.760.7522-甲基萘C11H1092.253.3731,3-二甲基萘-C12H1282.101.144萘C10H878.430.995邻苯二甲酸二辛酯C24H38O496.3171.496二十五烷C25H5269.462.727二十四烷C24H5072.421.168二十三烷C23H4879.281.229酞酸,丁基十四烷基酯C26H42O470.271.66109,10-蒽二酮,2,3-二甲氧基-C16H12O469.990.86112-苯甲酰氧基-1,1,10-三甲基-6,9-二乙氧基十氢化萘C20H26O470.802.26121-庚醇,5-甲基-2-(1-甲基乙烯基)-C11H22O77.091.22132,4-二叔丁基苯酚C14H22O80.170.84142,4,5,5,8a-五甲基-4a,5,6,7,8,8a-六氢-2H-苯并吡喃C14H24O80.060.81152(1H)-萘酮,八氢-4a,7,7-三甲基-C13H22O80.171.141617α-21β-28,30-双降藿烷C28H4872.830.7317二叔十二烷基二硫化物C24H50S267.411.411817β-雌二醇,3-脱氧-C18H24O74.850.8719植物醇C20H40O74.881.77205α-麦角甾-14-烯C28H4872.833.5980 ℃-20 MPa1碳酸,二十烷基乙烯基酯C23H44O361.930.932十三醇2-乙基-2-甲基-C16H34O66.870.713邻苯二甲酸二辛酯C24H38O497.0049.744环戊酮2-(1-甲基丙基)-C9H16O61.130.855环癸烯1-乙基-2-甲基-C13H24100.000.576正庚醚C14H30O73.422.707苯甲醛C7H6O60.480.818邻二氯苯C6H4Cl282.130.9795α-胆甾烷-3-酮,5-氯-6β-硝基-(7Cl,8Cl)C27H44ClNO3100.000.511014-甲基-5α-胆甾-8-烯-3-酮C28H46O100.000.51111-庚醇,5-甲基-2-(1-甲基乙烯基)-C11H22O65.570.6112间苯二甲酸二辛酯C24H38O480.0511.12131,1,6-三甲基-3-亚甲基-2-(3,6,9,13-四甲基-6-乙炔-10,14-二亚甲基-十五烷基-4-烯基)环己烷C33H5673.5515.78145α-麦角甾-14-烯C28H48100.0014.21

2.3.2 萃取物产气分析

对40 ℃-10 MPa和80 ℃-20 MPa的萃取物进行厌氧降解产甲烷实验,结果如图3所示。萃取物产气在10 d左右达到平衡,比煤样提前3~5 d,说明产甲烷菌群对于萃取物的利用更迅速,这可能是因为被萃取出来的有机物增大了与微生物的接触面积,提高了生物利用度。2种温压条件下萃取物最大产甲烷量分别为4.91 μmol/mL和3.37 μmol/mL,比空白对照组高出1~2倍,说明萃取物能够被微生物利用产生甲烷。结合萃余煤产气结果,说明ScCO2萃取对微生物降解产甲烷具有显著增强作用。

图3 40 ℃-10 MPa和80 ℃-20 MPa下萃取物的甲烷产量

Fig.3 Methane production of extracts under 40 ℃-10 MPa and 80 ℃-20 MPa

2.4.1 萃取率

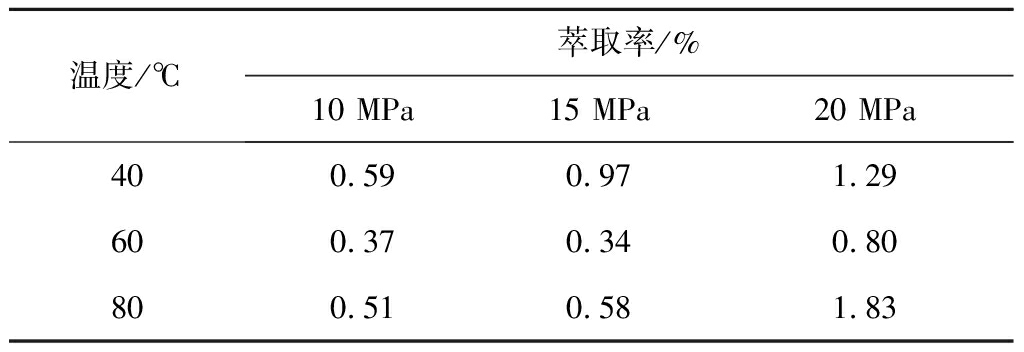

从表3中看出,各组样品的ScCO2萃取率普遍不高,这与以往研究结果[27]一致。虽然ScCO2可以削弱煤中有机物分子间作用力,打破共价键,导致小分子有机物从煤的大分子结构中分离出来[28-29],但ScCO2 携带的有机物很可能再次吸附在煤基质上,因此最终只有少量有机物与煤分离[30-31],导致检测到的萃取率较低。而大量被ScCO2作用的有机物仍残留在萃余煤中,有利于微生物降解,导致萃余煤产气量显著提高。

表3 不同温压下ScCO2对褐煤的萃取率

Table 3 ScCO2 extraction yields of lignite under various temperature and pressure conditions

温度/℃萃取率/%10 MPa15 MPa20 MPa400.590.971.29600.370.340.80800.510.581.83

2.4.2 DCM二次萃取结果分析

DCM作为一种萃取能力较强的有机溶剂,被广泛用于煤的萃取实验中。为了验证萃余煤中确实仍残留有大量可供微生物降解的有机物,使用DCM对

40 ℃-10 MPa和80 ℃-20 MPa下的萃余煤进行二次萃取,命名为40-10-D和80-20-D。结果显示,所有DCM萃余煤微生物降解产甲烷实验组的甲烷产量不超过5 μmol/g煤(图4),说明DCM已将煤中生物可利用有机物全部萃取,导致生物无法利用萃余煤。

图4 DCM萃余煤的累积甲烷产量

Fig.4 Accumulated methane production of residual coal extracted by DCM

在40-10-D和80-20-D萃取物中分别检测到48种和39种有机物,种类多于ScCO2萃取物,且大多有机物为脂肪族化合物、烃类化合物和含氧化合物(图5),这些化合物被认为是更容易被微生物降解利用的有机物[24,32]。研究结果证明,经过ScCO2萃取后,萃余煤中仍然含有大量微生物可利用有机物。

图5 DCM的萃取物成分

Fig.5 Composition of extracts by DCM

对原煤和萃取煤进行了氮气吸附测试,以阐明ScCO2萃取对煤物理结构的影响。结果表明,褐煤的孔隙结构主要由介孔(0.016 10 cm3/g)和大孔(0.008 19 cm3/g)组成,而微孔(0.000 323 cm3/g)极少(图6),这与前人研究结果[33] 一致。原煤比表面积和总孔容分别为4.222 7 m2/g和0.025 5 cm3/g。

图6 ScCO2萃取对于煤的孔隙结构的影响

Fig.6 Effect of ScCO2 extraction on the pore structure of coal

萃余煤比表面积和总孔容分别为3.337 1 m2/g和0.017 6 cm3/g。经过ScCO2处理,萃余煤微孔(0.000 294 cm3/g)、介孔(0.011 367 cm3/g)和大孔(0.005 387 cm3/g)的孔容均有不同程度的下降,导致总孔容下降约30.94%,比表面积下降约20.97%。GATHITU等[34]研究了ScCO2与褐煤的相互作用,发现微孔和介孔比表面积均减小;对原煤和ScCO2萃余煤脱气处理以消除杂质等阻塞效应后,发现ScCO2萃余煤微孔比表面积反而大于原煤脱气后的煤样。因此,ScCO2处理后孔隙体积和比表面积降低的原因,一方面是由于ScCO2吸附引起的煤基体膨胀所致[35],另一方面可能是由于萃取有机物在煤体中再吸附产生的堵孔效应。

姜仁霞等[36]探讨了煤的ScCO2萃取机理,认为ScCO2萃取过程涉及有机小分子的溶解、有机小分子随ScCO2的扩散以及ScCO2的吸附作用。因此,ScCO2 所溶解的有机物在煤中的运移、滞留,从而影响煤的孔隙结构。

(1)不同温压条件下ScCO2萃余煤甲烷产量均高于原煤。40 ℃-10 MPa条件下萃余煤甲烷产量最大,为245.46 μmol/g煤,比原煤甲烷产量高出84.68%。萃取物中含有大量微生物可利用组分,产气实验证实其可被菌群利用产甲烷。由此说明,ScCO2萃取作用能够促进微生物降解,从而显著提高煤层气产量。

(2)气态和液态CO2处理残煤的甲烷产量略高于原煤而显著低于ScCO2萃余煤,说明ScCO2的独特性质是促进微生物增产煤层气的关键因素。

(3)ScCO2萃取率较低,小于2%。对ScCO2萃余煤进行DCM二次萃取,残煤厌氧降解后几乎无甲烷生成。且DCM萃取物中含有丰富的有机物。说明ScCO2萃取有机物在煤中大量滞留,导致萃余煤的产气量显著提高。

(4)ScCO2引起的萃取有机物运移、吸附和煤基质溶胀导致萃余煤的总孔容和比表面积降低。

[1] SCOTT A R.Improving coal gas recovery with microbially enhanced coalbed methane[A].Coalbed Methane:Scientific,Environmental and Economic Evaluation[C].Springer,1999:89-110.

[2] 琚宜文,李清光,颜志丰,等.煤层气成因类型及其地球化学研究进展[J].煤炭学报,2014,39(5):806-815.

JU Yiwen,LI Qingguang,YAN Zhifeng,et al.Origin types of CBM and their geochemical research progress[J].Journal of China Coal Society,2014,39(5):806-815.

[3] 郭红玉,罗源,马俊强,等.不同煤阶煤的微生物增透效果和机理分析[J].煤炭学报,2014,39(9):1886-1891.

GUO Hongyu,LUO Yuan,MA Junqiang,et al.Analysis of mechanism and permeability enhancing effect via microbial treatment on different-rank coals[J].Journal of China Coal Society,2014,39(9):1886-1891.

[4] 王爱宽.褐煤本源菌生气特征及其作用机理[J].煤炭学报,2012,37(2):355-356.

WANG Aikuan.Generation and mechanism of gas from brown coal under action of parent bacterium[J].Journal of China Coal Society,2012,37(2):355-356.

[5] 刘会虎,兰天贺,胡宝林,等.淮南潘集外围深部煤层气地球化学特征及成因[J].煤炭学报,2018,43(2):498-506.

LIU Huihu,LAN Tianhe,HU Baolin,et al.Geochemical characteristics and its origins of CBM in deep-seated coal seam around Panji mining area of Huainan[J].Journal of China Coal Society,2018,43(2):498-506.

[6] JONES E J P,VOYTEK M A,WARWICK P D,et al.Bioassay for estimating the biogenic methane-generating potential of coal samples[J].International Journal of Coal Geology,2008,76(1):138-150.

[7] PARK S Y,LIANG Y N.Biogenic methane production from coal:A review on recent research and development on microbially enhanced coalbed methane(MECBM)[J].Fuel,2016,166:258-267.

[8] 王爱宽,秦勇,邵培.实验室条件下褐煤生物气生成的化学影响因素[J].煤炭学报,2016,41(4):948-953.

WANG Aikuan,QIN Yong,SHAO Pei.Chemical factors influencing lignite biogenic gas production in laboratory condition[J].Journal of China Coal Society,2016,41(4):948-953.

[9] ZHI S,ELSWORTH D,WANG J,et al.Hydraulic fracturing for improved nutrient delivery in microbially-enhanced coalbed-methane(MECBM)production[J].Journal of Natural Gas Science and Engineering,2018,60:294-311.

[10] HAQ S R,TAMAMURA S,LGARASHI T,et al.Characterization of organic substances in lignite before and after hydrogen peroxide treatment:Implications for microbially enhanced coalbed methane[J].International Journal of Coal Geology,2018,185:1-11.

[11] 夏大平,苏现波,吴昱,等.不同预处理方式和模拟产气实验对煤结构的影响[J].煤炭学报,2013,38(1):129-133.

XIA Daping,SU Xianbo,WU Yu,et al.Effect of experiment of different pretreatment methods and simulating biogenic methane production on coal structure[J].Journal of China Coal Society,2013,38(1):129-133.

[12] MARR R,GAMSE T.Use of supercritical fluids for different processes including new developments-A review[J].Chemical Engineering and Processing:Process Intensification,2000,39(1):19-28.

[13] KUMAR S K,JOHNSTON K P.Modelling the solubility of solids in supercritical fluids with density as the independent variable[J]. The Journal of Supercritical Fluids,1988,1(1):15-22.

[14] 岳立新,孙可明,郝志勇.低渗透煤层注超临界CO2增透微观机理研究[J].煤炭科学技术,2016,44(12):85-90,117.

YUE Lixin,SUN Keming,HAO Zhiyong.Study on micro-mechanism of permeability improvement with supercritical CO2 injection in low permeability seam[J].Coal Science and Technology,2016,44(12):85-90,117.

[15] HU Runan,WANG Zhicai,LI Lei,et al.Effect of solvent extraction pretreatments on the variation of macromolecular structure of low rank coals[J].Journal of Fuel Chemistry and Technology,2018,46(7):778-786.

[16] LIU S,MA J,SANG S,et al.The effects of supercritical CO2 on mesopore and macropore structure in bituminous and anthracite coal[J].Fuel,2018,223:32-43.

[17] 张攀攀,郭红光,段凯鑫,等.无烟煤厌氧代谢产物对其纳米孔隙的影响[J].煤炭学报,2020,45(11):3841-3852.

ZHANG Panpan,GUO Hongguang,DUAN Kaixin,et al.Effects of microbial anaerobic metabolites on nanoporosity of anthracite[J]. Journal of China Coal Society,2020,45(11):3841-3852.

[18] LI Hongjun,CHANG Qinghua,GAO Rui,et al.Fractal characteristics and reactivity evolution of lignite during the upgrading process by supercritical CO2extraction[J].Applied Energy,2018,225:559-569.

[19] GUO Hongguang,CHENG Yatong,HUANG Zaixing,et al.Factors affecting co-degradation of coal and straw to enhance biogenic coalbed methane[J].Fuel,2019,244:240-246.

[20] TAMAMURA S,MURAKAMI T,ARAMAKI N,et al.Reaction of lignite with dilute hydrogen peroxide to produce substrates for methanogens at in situ subsurface temperatures[J]. International Journal of Coal Geology,2016,167:230-237.

[21] THOMMES M,KANEKO K,NEIMARK A V,et al.Physisorption of gases,with special reference to the evaluation of surface area and pore size distribution(IUPAC Technical Report)[J].Pure And Applied Chemistry,2015,87(9-10):1051-1069.

[22] CHEN Tianyu,ZHENG Hang,HAMILTON S,et al.Characterisation of bioavailability of Surat Basin Walloon coals for biogenic methane production using environmental microbial consortia[J]. International Journal of Coal Geology,2017,179:92-112.

[23] EVANS W C,FUCHS G.Anaerobic degradation of aromatic compounds[J].Annual Review of Microbiology,1988,42(1):289-317.

[24] JONES E J,VOYTEK M A,CORUM M D,et al.Stimulation of met-hane generation from nonproductive coal by addition of nutrients or a microbial consortium[J].Applied and Environmental Microbiology,2010,76(21):7013-7022.

[25] GUO Hongguang,ZHANG Yiwen,ZHANG Jinlong,et al.Character-ization of anthracite-degrading methanogenic microflora enriched from Qinshui Basin in China[J].Energy & Fuels,2019,33(7):6380-6389.

[26] 陈林勇,王保玉,邰超,等.无烟煤微生物成气中间代谢产物组成及其转化[J].煤炭学报,2016,41(9):2305-2311.

CHEN Linyong,WANG Baoyu,HE Chao,et al.Composition and conversion of intermediate products in the process of anthracite gasification by microorganism[J].Journal of China Coal Society,2016,41(9):2305-2311.

[27] KOLAK J J,HACKLEY P C,RUPPERT L F,et al.Using ground and intact coal samples to evaluate hydrocarbon fate during supercritical CO2 injection into coal beds:Effects of particle size and coal moisture[J].Energy & Fuels,2015,29(8):5187-5203.

[28] TSOTSIS T T,PATEL H,NAJAFI B F,et al.Overview of laboratory and modeling studies of carbon dioxide sequestration in coal beds[J].Industrial & Engineering Chemistry Research,2004,43(12):2887-2901.

[29] SHENG Q T,SHEN J,NIU Y X,et al.The effect of small molecular compounds in coal on quick direct coal liquefaction at a high temperature[J].Energy Sources,Part A:Recovery,Utilization,and Environmental Effects,2015,37(1):28-37.

[30] WANG Qianqian,ZHANG Dengfeng,WANG Haohao,et al.Influence of CO2 exposure on high-Pressure methane and CO2 adsorption on various rank coals:Implications for CO2 sequestration in coal seams[J].Energy & Fuels,2015,29(6):3785-3795.

[31] RANATHUNGA A S,PERERA M S A,RANJITH P G,et al.An experimental investigation of applicability of CO2 enhanced coal bed methane recovery to low rank coal[J].Fuel,2017,189:391-399.

[32] ![]() M,DAWSON K,et al.Biogeochemistry of microbial coal-bed methane[J].Annual Review of Earth and Planetary Sciences,2011,39:617-656.

M,DAWSON K,et al.Biogeochemistry of microbial coal-bed methane[J].Annual Review of Earth and Planetary Sciences,2011,39:617-656.

[33] 秦志宏,张豪非,戴冬瑾,等.新峪焦精煤中硫在族组分间的赋存规律研究[J].燃料化学学报,2014,42(11):1286-1294.

QIN Zhihong,ZHANG Haofei,DAI Dongjin,et al.Study on occurrence of sulfur in different group components of Xinyu clean coking coal[J].Journal of Fuel Chemistry and Technology,2014,42(11):1286-1294.

[34] GATHITU B B,CHEN W-Y,MCCLURE M.Effects of coal interaction with supercritical CO2:Physical structure[J].Industrial & Engineering Chemistry Research,2009,48(10):5024-5034.

[35] ANGGARA F,SASAKI K,RODRIGUES S,et al.The effect of megascopic texture on swelling of a low rank coal in supercritical carbon dioxide[J].International Journal of Coal Geology,2014,125:45-56.

[36] 姜仁霞.超临界CO2萃取煤中有机质试验装置的建立及萃取实验研究[D].青岛:山东科技大学,2013.

JIANG Renxia.Experimental setup establishment of coal organic matter extraction of supercritical CO2 and extraction investigation[D].Qingdao:Shandong University of Science and Technology,2013.