榆神矿区地处西部干旱与半干旱地区,毛乌素沙漠与陕北黄土高原的接壤地带,是我国陕北煤炭基地的重要组成部分,近地表第四系萨拉乌苏组松散孔隙含水层是区内惟一具有供水意义和重要生态价值的含水层[1],为矿区保水采煤的目标保护层[2]。煤层开采形成的采动裂隙发育至基岩含水层内部甚至近地表的松散层含水层,导致含水层地下水沿采动导水裂隙间接或直接涌入采掘空间,一般形成大而稳定的顶板涌水问题[3],也加剧了矿区水资源短缺局面以及生态环境的负效应[4-5]。因此,煤层开采过程中顶板水害防控与地下水资源协同保护是煤炭可持续开发面临的一项主要问题。

针对矿区“煤水”协调问题,董书宁等[6-7]系统提出了西部矿区典型顶板水害防控技术,彭苏萍等[8]系统总结了煤矿区生态环境修复关键技术。李智学、申小龙等[9-10]系统分析了榆神矿区最上可采煤层赋存特征、上覆主要含(隔)水层空间分布规律及组合类型,李文平等[11]根据主采煤层上覆基岩、松散含水层及隔水层的空间分布特征,将榆神府矿区“保水采煤”工程地质条件分为砂土基型、砂基型、土基型、基岩型、烧变岩型5类,王双明等[1]根据“三图预测法”将榆神矿区划分为贫水、保水限定、可控保水和自然保水4个保水采煤类型分区。王启庆等[12]根据煤层开采对松散层潜水的影响程度,将矿区划分为不涌水、轻微涌水、一般涌水、严重涌水4个分区,邓念东等[13]把白垩系洛河组含水层也作为保水对象,将矿区划分为沙-土-洛-基型、沙-土-基型、沙-基型、无水开采区与烧变岩型5个保水开采分区,笔者[14]采用地下水数值模拟方法研究了神东矿区浅埋煤层开采松散含水层涌水量,相关研究成果丰富了矿区保水采煤技术实践。

目前保水采煤理论与技术主要以“覆岩分带理论”为研究基础,以分析不同采煤条件下导水裂隙带发育高度与覆岩含水层的空间关系为研究重点[15-16],其基本认识为导水裂隙未沟通保水目标层或隔水土层,未造成地下水资源大量漏失,即认为可以实现保水开采。陕北榆神矿区分4个规划期,各期主采煤层赋存特征差异较大,针对煤层开采引起含水层涌水规律的相关研究大多集中在开采程度高、开采煤层埋深相对较浅的一、二期规划区以及北部的神府矿区,其研究成果在榆神中深部的三、四期规划区应用方面存在一定局限性。笔者通过系统整理分析榆神矿区主采煤层地质、水文地质特征以及导水裂隙带的相关研究成果,总结榆神矿区主采煤层开采含水层3种涌水模式,并采用地下水系统数值分析手段,构建了矿区典型煤矿工作面尺度上3种模式的涌水分析模型,定量分析了采煤导致的含水层地下水的涌水规律。

1 主采煤层水文地质结构特征

1.1 主采煤层赋存特征

榆神矿区位于毛乌素沙漠与陕北黄土高原的接壤地带,地貌单元上划分为风沙地貌、黄土地貌及河谷地貌3种类型,地势呈西北高东南低,地层总体表现为向北西缓倾的单斜,地质构造相对简单。

矿区含煤地层为侏罗系中统延安组(J2y),覆岩由下至上依次为侏罗系直罗组(J2z)、安定组(J2a),白垩系洛河组(K1l),新近系保德组(N2b),第四系离石组(Q2l)、第四系萨拉乌苏组(Q3s),以及风积层(Q4eol)与冲积层(Q4al)。如图1,2所示,由于地层剥蚀,侏罗系延安组含煤地层保存不完整,矿区从东南向西北可采煤层5-2,4-2,3-1,2-2,1-2呈阶梯状分布,覆岩层组合及厚度差异较大,其中东部的榆神二期主采煤层由西北向东南依次为5-2,4-2,3-1;中东部的榆神一期主采煤层为2-2,中部榆神三期主采煤层除小壕兔一、二号井田为1-2外,其他区域均为2-2;西部榆神四期主采煤层为1-2,2-2,总体上各主采煤层埋深由东至西逐步增大。

图1 榆神矿区主采煤层埋深等值线(据文献[9]修改)

Fig.1 Buried depth contour of the top mineable coal seam seams in Yushen mining area(revised according to Reference[9])

图2 矿区典型地质钻孔柱状

Fig.2 Hydrogeologic histogram of typical boreholes in mining area

1.2 主采煤层覆岩含、隔水层

根据榆神矿区主采煤层覆岩的地层岩性,以及地层剥蚀、风化、烧变等作用,划分主采煤层覆岩含、隔水层见表1。

表1 榆神矿区主采煤层覆岩含隔水层特征

Table 1 Characteristic table of overlying aquifer and aquifer of the top mineable coal seam in Yushen mining area

地层系统组类型岩性特征富水性分布特征第 四 系 新 近 系全新统上更新统中更新统上新冲积层 Q4al风积层Q4eol萨拉乌苏组Q3s离石组 Q2l保德组 N2b松散孔隙含水层隔水层隔水层以细沙、粉沙、粉土和粉质黏土为主 以固定、半固定沙丘形式覆盖于其他地层之上 以灰黄色、褐色及灰黑色粉、细、中沙为主以浅棕黄、褐黄色亚黏土及亚沙土为主,抗裂性隔水特征明显以浅红色、棕红色黏土及亚黏土,含不规则的钙质结核,抗裂隔水性特征明显弱-强极弱极弱河谷区 全区广泛分布 全区广泛分布矿内分布不连续全区大部分布白 垩 系下统侏 罗 系 中统洛河组 K1l安定组 J2a直罗组 J2z延安组 J2y风化基岩-基岩裂隙含水层风化基岩裂隙发育由上而下减弱,富水性较强于下部正常岩段,一般厚度为20 m,全区分布。矿区由西到东发育层位依次为洛河组、安定组、直罗组与延安组以紫红、棕红色中粗粒长石砾岩为主上部以泥岩、砂质泥岩为主,下部以中~粗 砂岩为主上部以泥岩、砂泥岩为主,下部以中~粗 粒长石砂岩为主含可采煤层13 层,以浅灰、深灰色砂岩及泥岩为主烧变岩孔洞-裂隙含水层因2-2,3-1,4-2,5-2煤层自燃顶板塌落及后期风化作用形成裂隙孔洞发育富水性好的烧变岩含水层中-弱弱弱-中弱-中弱-强三期规划区的西部与四期大部 一期西部,三、四期大部三期、四期全区分布,一期西部与二期西北部全区 二期各大沟谷两侧条带状分布

松散孔隙潜水含水层组,主要指第四系冲积层(Q4al)、风积层(Q4eol)以及萨拉乌苏组(Q3s),基本全区分布,一般3层具有较为统一的水力联系,一般划分为松散孔隙潜水含水层组,据矿区金鸡滩、锦界、凉水井、曹家滩、大保当、尔林滩、尔林兔等井田抽水试验资料,渗透系数0.013~23.582 m/d,水位埋深一般小于3 m,富水性大部分较好,是矿区煤层开采保水的目标含水层。

基岩裂隙含水层组,矿区主采煤层上覆基岩地层自下而上分别为延安组(J2y)、直罗组(J2z)、安定组(J2a)、洛河组(K1l)正常基岩地层,据榆神一期杭来湾、曹家滩、大保当、神树畔等井田,二期香水河、何兴梁、马王庙、朱家塔等井田,三期小壕兔一号、二号及小保当一号等井田,四期尔林滩、孟家湾西、中鸡等井田对不同基岩含水层抽水试验资料显示,渗透系数0.006~2.135 m/d,基岩裂隙含水层组富水性一般较弱。如图2所示,基岩厚度总体由东南向西北增厚,由于上部受风化剥蚀作用影响,在矿区中东部区(一、二期),洛河组(K1l)基岩地层缺失,主采煤层上覆基岩层岩性和厚度变化较大。

风化基岩含水层,基岩顶部岩石顶面受到不同程度的风化,结构杂乱,松软易碎,受地形地貌、上覆含水层特征、风化程度等影响,风化基岩含水层富水性变化较大,渗透系数0.012~4.992 m/d[17-18],矿区由西向东发育层位依次为洛河组(K1l)、安定组(J2a)、直罗组(J2z)与延安组(J2y)[19]。

烧变岩孔洞裂隙含水层,是指因煤层自燃顶板塌落及后期风化等形成裂隙孔洞发育的烧变岩带,由于岩层破碎,透水性好,其富水性变化较大,主要与自燃煤层、烧变岩特征及烧变岩上覆松散含水层组的富水性有关,其分布范围相对局限,主要在二期各大沟谷两侧呈条带状分布,据锦界、西湾、榆树湾、杭来湾、上河、高家界、河兴梁等井田勘探钻孔抽水试验资料,渗透系数0.006~74.103 m/d。

主隔水层是由第四系离石组(Q2l)黄土和新近系保德组(N2b)红土共同组成的隔水土层[20],是上覆松散孔隙潜水含水层组的直接隔水底板,基本全区分布,该土层组的连续性、厚度、天然及采动后的渗透系数变化等对保护松散含水层意义重大,被定为榆神矿区的隔水关键层[21-22]。

亚隔水层,在榆神矿区中-深煤层区,侏罗系地层中渗透能力弱的泥岩、砂质泥岩、粉砂岩与渗透能力较好的中、细粒砂岩相互交错,其中侏罗系安定组地层(J2a)以含泥岩、砂质泥岩沉积为主,厚度较为稳定,一般划分为相对隔水层[23-24]。

2 主采煤层开采含水层涌水模式

由于采动导水裂隙具有极强的导水能力,是引起含水层涌水的控制因素,通过分析榆神矿区主采煤层开采形成的导水裂隙带与上覆含、隔水层组的空间组合关系,以及引起含水层涌水特征,提出榆神矿区最上煤层开采含水层涌水模式。

2.1 榆神矿区主采煤层采动导高分析

通过整理分析榆神矿区生产矿井导水裂隙带高度研究成果,见表2。矿区煤层埋深、覆岩结构差异明显,主采煤层开采裂采比变化较大(15~28倍),均值23倍。其中榆神东部与南部浅埋煤层区,主采煤层开采(如4-2,3-1煤层等)导水裂隙易沟通风化基岩与松散含水层(如柳巷、凉水井、锦界等煤矿);中南部中埋深煤层区,由于主采煤层2-2厚度大,曹家滩、榆树湾等生产矿井一般采用分层开采,实测分层开采导水裂隙一般发育至基岩内部,通过相似材料模拟得出一次采全高条件下导水裂隙易发育至土层甚至松散层内[21,27];中部与西部深埋煤层区,主采煤层(如2-2,1-2煤层)开采导水裂隙仅发育在基岩含水层内部(如榆树湾、金鸡滩、隆德、小壕兔等煤矿)。

表2 榆神矿区部分矿井开采覆岩导水裂隙带测试统计

Table 2 Detection results of water flowing fractured zone in some mines in Yushen mining area

矿井名称煤层测试孔号采高/m导高/m裂采比揭露层位方法曹家滩[25]2-25.00123.4024.68基岩含水层实测JSD25.50107.4919.54JT25.50109.7219.95金鸡滩[26]2-2JT35.50111.4920.27基岩含水层实测JT45.50126.4023.00JT55.50146.1826.58Y35.00130.5026.10Y55.00138.9027.78基岩含水层实测榆树湾[27-28]2-2Y45.00137.3027.465.00130.0026.00基岩含水层实测6.00148.0024.67土层相似材料模拟7.00168.0024.00H34.50108.3224.10杭来湾[29]2-2H44.50114.3825.40基岩含水层实测H54.50107.8323.96H74.5093.8720.86CH013.9675.7819.14隆德[30]2-2CH023.9671.6618.10基岩含水层实测CH033.9676.8519.41柳巷[31]3(2-2)L17.90117.8414.90松散层实测锦界[32]3-1冒13.00≥45.72≥15.24风化基岩含水层实测凉水井[33]4-23.00≥70.00≥23.33松散层实测

2.2 煤层开采含水层涌水模式

根据榆神矿区主采煤层采动导水裂隙与覆岩含(隔)水层的空间组合关系,以及不同组合关系下含水层涌水特征,提出3种涌水模式:

(1)浅埋煤层侧向直接涌水型(图3(a))。榆神矿区东部浅埋煤层区(一、二期)主采煤层开发时导水裂隙带穿越离石、保德组发育至地表风积沙等松散层内,在工作面顶部局部区段内的松散含水层被迅速疏干,该区段含水层不能得到外围含水层侧向补给,出现干涸;而工作面外围的松散含水层地下水会以侧向排泄的形式沿着导水裂缝侧向边界进入采空区内,造成松散含水层与基岩裂隙含水层地下水沿导水裂隙侧向直接涌入井下,形成典型的“侧向直接型”涌水模式。

图3 煤层采动含水层涌水模式示意

Fig.3 Schematic diagram of water inrush in aquifer under the influence of coal seam mining

(2)中深煤层侧向与垂向复合涌水型。榆神矿区中部(三期)煤层埋深相对较大(150~400 m),如图3(b)所示,采动导水裂隙直接揭露基岩含水层后延伸至离石、保德组主隔水土层底部或内部,造成基岩含水层地下水大量漏失,基岩含水层以侧向涌水为主;而采动导水裂隙与松散含水层之间残留一定厚度的隔水土层,由于基岩含水层地下水的大量漏失致使与松散含水层间的水力梯度增大,以及土层弯曲变形后垂向渗透能力提高,导致松散含水层沿主隔水土层越流涌水,李涛等[34-35]采用水-电相似模拟技术,测试得出当采后有效隔水层厚度为42.6 m的离石黄土或21.0 m的保德红土时,潜水才不会显著漏失,可见中深煤层开采易形成“侧向与垂向复合”涌水模式。

(3)深埋煤层侧向涌水与垂向弱涌水型。榆神矿区西部(三、四期)煤层埋深相对较大(>400 m),如图3(c)所示,采动导水裂隙发育至直罗组、延安组基岩含水层内部或安定组亚隔水层内,采动裂隙直接揭露的直罗组、延安组基岩含水层沿导水裂隙侧向直接涌水,安定组亚隔水层顶部的洛河组基岩含水层间接越流涌水,而近地表的松散含水层由于存在安定组亚隔水层与离石组、保德组主隔水土层保护,地下水越流漏失微弱,易形成基岩含水层侧向涌水与垂向复合隔水保护弱涌水模式。

3 典型煤矿煤层开采含水层涌水规律

3.1 采煤工作面含水层涌水分析方法

为了便于定量分析煤层开采含水层涌水规律,根据含水层与导水裂隙带间的地下水运动转化特征,将导水裂隙与正常覆岩接触面概化成地下水达西渗流的定水压边界(孔隙水压力p=0),合理避免了导水裂隙带难以数值刻画问题,其模拟结果更接近于真实的渗流场,在COMSOL数值分析中,将导水裂隙带范围概化成倒梯形,在涌水模型中分别对梯形各面达西流速U进行面积积分,即![]() 为导水裂隙带概化形成倒梯形面积采用稳定流分析方法,计算得出来自导水裂隙带外围侧向和顶部各含水层的地下水涌水量[36],以建立采煤工作面尺度上含水层涌水分析模型。

为导水裂隙带概化形成倒梯形面积采用稳定流分析方法,计算得出来自导水裂隙带外围侧向和顶部各含水层的地下水涌水量[36],以建立采煤工作面尺度上含水层涌水分析模型。

为了削弱模型边界效应影响,在采煤工作面尺度上的含水层涌水模型中,采用无限元域方法,将模拟区外围定义为无限展布的含水层[37],即将充水含水层外围数值处理成“大范围”的无限展布的充水含水层,减少了“小范围”人为水头边界与流量边界对预测精度的影响,宽度设置为3 000 m,走向为100 m,图幅显示比例调整为x∶y∶z=1∶10∶3。其中覆岩各含水层主要水力参数根据各矿井含水层实际测试资料给定(表3)。

3.2 浅埋煤层侧向直接涌水型

凉水井井田位于榆神二期中北部,主采为4-2煤层,煤层厚度0.8~4.2 m,最大埋深150 m,煤层上覆松散层孔隙潜水含水层(均厚13.46 m),离石与新保德组土层(均厚31.61 m),基岩与风化基岩含水层(一般厚度38 m),4-2煤层采动导水裂隙已揭露松散含水层,为侧向直接流失型涌水模式。

表3 模型中含、隔水层渗透系数

Table 3 Permeability coefficients of main aquifers in the model

含(隔)水层渗透系数/(m·d-1)松散孔隙潜水含水层组1.5~3.0基岩裂隙含水层组0.03~0.08风化基岩含水层0.085~1.500主隔水土层0.001~0.008亚隔水土层0.010~0.003

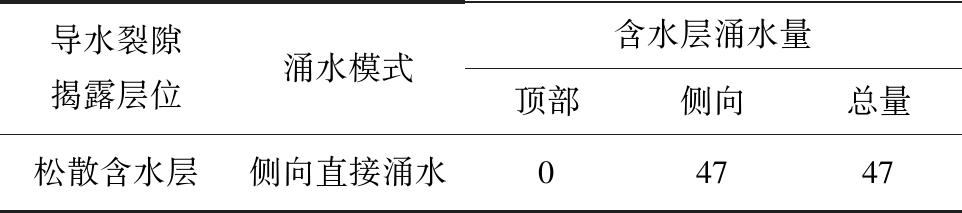

由于采动裂隙直接发育至松散含水层,如图4所示,地下水流场受采动影响较大,形成以导水裂隙带为中心的降落漏斗,其中工作面顶部与侧向一定范围内的含水层被疏干(空白区段),积分得出各含水层向导水裂隙的总涌水量为47 m3/h,均来自松散层、基岩与风化基岩含水层的侧向涌水。

图4 凉水井煤矿含水层流场特征

Fig.4 Characteristics of aquifer flow field in Liangshuijing Coal Mine

表4 凉水井煤矿含水层涌水量

Table 4 Water inrush of aquifer in Liangshuijing Coal Mine m3/h

导水裂隙揭露层位涌水模式含水层涌水量顶部侧向总量松散含水层侧向直接涌水04747

3.3 深埋煤层侧向涌水与垂向弱涌水型

小壕兔一号井田位于榆神四期西部,最上开采煤层为1-2号煤层,均厚4.8 m,埋深约为400 m,煤层上覆松散含水层(25 m),离石组与保德组隔水土层(48 m),洛河组基岩含水层(66 m)、安定组亚隔水土层(136 m)、以及直罗组与延安组基岩含水层(132 m),按照23倍裂采比分析,1-2煤层采动导水裂隙带高度约110.4 m,发育至直罗与延安组基岩含水层顶部,未揭露安定组亚隔水层,其涌水模式属于侧向与垂向复合隔水保护弱涌水型。

如图5、表5所示,导水裂隙对直罗组与延安组基岩含水层流场影响较大,形成较为明显的降落漏斗,由于安定组与离石组、保德组隔水层复合保护近地表松散含水层,地下水流场基本未发生变化,含水层总涌水量为21.87 m3/h,以侧向涌水为主,顶部涌水量仅为3.27 m3/h。

图5 小壕兔煤矿含水层流场特征

Fig.5 Characteristics of aquifer flow field in Xiaohaotu Coal Mine

表5 小壕兔煤矿含水层涌水量

Table 5 Water inrush of aquifer in in Xiaohaotu Coal Mine m3/h

揭露层位涌水模式含水层涌水量顶部侧向总量直罗组与延安基岩层复合隔水保护微涌水3.2718.6021.87

3.4 中深煤层侧向与垂向复合微涌水型

曹家滩井田位于榆神矿区一期规划区中部,主采煤层为2-2煤层,平均煤厚达11.20 m,埋深一般为300 m左右,采煤方法为分层综采。煤层上覆松散层孔隙潜水含水层(10 m),离石组与保德组土层(70 m),风化基岩含水层(26 m)、安定组亚隔水土层(22 m)以及直罗组与延安组基岩含水层(175 m)。按照23倍裂采比分析,2-2煤层分层开采高度为5 m,导高为115 m,发育至直罗与延安组基岩含水层中部;一次采全高10 m,导高为230 m,发育至离石与新保德组土层下部,均未贯通土层,其涌水模式为侧向与垂向复合涌水型。

如图6,表6所示,上分层开采导高为115 m时,导水裂隙发育至直罗与延安组基岩含水层内部,基岩含水层以导水裂隙为中心形成明显的地下水降落区,由于地表松散含水层受土层的保护,地下水流场基本未发生变化。各含水层向导水裂隙的总涌水量为35.84 m3/h,其中侧向涌水量约为23.17 m3/h,顶部含水层(含风化基岩含水层、土层与松散含水层)地下水的垂向越流涌水量约为12.67 m3/h;一次采全高,导高为230 m时,导水裂隙直接贯通基岩含水层,发育至风化基岩含水层底部,总涌水量增至130.31 m3/h,其中基岩含水层与风化基岩含水层侧向涌水量92.65 m3/h,由于风化基岩含水层与近地表松散含水层之间的水力梯度增大,导水裂隙顶部的含水层地下水的越流涌水量增至37.66 m3/h,导致地表松散含水层地下水流场发生明显变化,工作面顶部地下水流向发生逆转。

图6 曹家滩煤矿含水层流场特征

Fig.6 Characteristics of groundwater flow field affected by coal seam mining in Caojiatan Coal Mine

表6 曹家滩煤矿含水层涌水量

Table 6 Water inrush of aquifer in in Xiaohaotu coal mine

导水裂隙带高度/m揭露层位涌水模式含水层涌水量/(m3·h-1)侧向垂向总量115基岩含水层中深侧向与垂向23.1712.6735.84230风化基岩含水层复合微涌水92.6537.66130.31

为了进一步分析导高对含水层涌水量的影响规律,分别模拟了该煤层开采导高在50~250 m条件下含水层总涌水量(图7),结果显示,导高越大,总涌水量越大,当导高小于180 m时,导水裂隙发育至基岩含水层内部,尚未沟通风化基岩含水层,含水层涌水量增加幅度不大;当导高大于180 m时,由于导水裂隙揭露富水性较好的风化基岩含水层,导致含水层涌水量增加幅度较大,由此可见,通过限高、分层开采等采煤方法,抑制导水裂隙高度与覆岩强含水层的接触关系,是实现顶板水害防控与水资源协同保护的重要措施。

图7 不同导水裂隙高度下覆岩含水层涌水量曲线

Fig.7 Water inrush curve of aquifer groundwater under different height of water-conducting fractured zone

4 结 论

(1)通过分析榆神矿区主采煤层覆岩结构特征,将矿区主采煤层覆岩含(隔)水层划分为松散孔隙、基岩与风化裂隙、烧变岩孔洞裂隙4个含水层组,以及主、亚2个隔水保护土层。

(2)通过分析主采煤层采动导水裂隙与覆岩含(隔)水层组的空间组合关系,提出浅埋煤层侧向直接涌水、中深煤层侧向与垂向复合涌水、深部煤层复合隔水保护微涌水3种含水层涌水模式。

(3)采用COMSOL数值分析方法,分别以凉水井、小壕兔、曹家滩井田为例,定量模拟分析了3种模式涌水规律,其中浅浅埋煤层侧向直接流失型(凉水井井田)工作面顶部含水层被疏干,各含水层均为侧向涌水,涌水总量为47 m3/h;深埋煤层侧向与垂向复合隔水保护弱涌水型(小壕兔1号井田),含水层涌水总量为21.87 m3/h,以基岩含水层侧向涌水为主;中深煤层侧向与垂向复合微涌水型(曹家滩井田),煤层分层开采条件下导水裂隙发育至基岩含水层内部,含水层侧向涌水量为23.17 m3/h,垂向涌水量为12.67 m3/h;一次采全高条件下由于导水裂隙发育至风化基岩含水层底部,垂向越流加剧,涌水总量增至131 m3/h;可见通过限高、分层开采抑制导水裂隙发育高度是实现顶板水害防控与水资源协同保护的重要措施。

[1] 王双明,黄庆享,范立民,等.生态脆弱矿区含(隔)水层特征及保水开采分区研究[J].煤炭学报,2010,35(1):7-14.

WANG Shuangming,HUANG Qingxiang,FAN Limin,et al.Study on overburden aquclude and water protection mining regionazation in the ecological fragile mining area[J].Journal of China Coal Society,2010,35(1):7-14.

[2] 仵拨云,彭捷,向茂西,等.榆神府矿区保水采煤受保护萨拉乌苏组含水层研究[J].采矿与安全工程学报,2018,35(5):984-990.

WU Boyun,PENG Jie,XIANG Maoxi,et al.Study on the aquifer of the Salawusu Formation protected by water-retaining mining in Yushenfu mining area[J].Journal of Mining & Safety Engineering,2018,35(5):984-990.

[3] FAN Limin,MA Xiongde.A review on investigation of water-preserved coal mining in western China[J].International Journal of Coal Science & Technology,2018,5(4):411-416.

[4] 范立民,马雄德,冀瑞君.西部生态脆弱矿区保水采煤研究与实践进展[J].煤炭学报,2015,40(8):1711-1717.

FAN Limin,MA Xiongde,JI Ruijun.Progress in research and practice of water-retaining coal mining in ecologically fragile mining areas in Western China[J].Journal of China Coal Society,2015,40(8):1711-1717.

[5] 贺卫中,向茂西,刘海南,等.榆神府矿区地面塌陷特征及环境问题[J].煤田地质与勘探,2016,44(5):131-135.

HE Weizhong,XIANG Maoxi,LIU Hainan,et al.Ground subsidence and its environment problems in Yushenfu mining area[J].Coal Geology & Exploration,2016,44(5):131-135.

[6] 董书宁,姬亚东,王皓,等.鄂尔多斯盆地侏罗纪煤田典型顶板水害防控技术与应用[J].煤炭学报,2020,45(7):2367-2375.

DONG Shuning,JI Yadong,WANG Hao,et al.Prevention and control technology and application of roof water disaster in Jurassic coal field of Ordos Basin[J].Journal of China Coal Society,2020,45(7):2367-2375.

[7] 乔伟,靳德武,王皓,等.基于云服务的煤矿水害监测大数据智能预警平台构建[J].煤炭学报,2020,45(7):2619-2627.

QIAO Wei,JIN Dewu,WANG Hao,et al.Development of big data intelligent early warning platform for coal mine water hazard monitoring based on cloud service[J].Journal of China Coal Society,2020,45(7):2619-2627.

[8] 彭苏萍,毕银丽.黄河流域煤矿区生态环境修复关键技术与战略思考[J].煤炭学报,2020,45(4):1211-1221.

PENG Suping,BI Yinli.Strategic consideration and core technology about environmental ecological restoration in coal mine areas in the Yellow River basin of China[J].Journal of China Coal Society,2020,45(4):1211-1221.

[9] 李智学,申小龙,李明培,等.榆神矿区最上可采煤层赋存规律及开采危害程度[J].煤田地质与勘探,2019,47(3):130-139.

LI Zhixue,SHEN Xiaolong,LI Mingpei,et al.Occurrence regularity of uppermost minable coal seams and their harmful level of mining in Yushen mining area[J].Coal Geology & Exploration,2019,47(3):130-139.

[10] 李智学,李明培,申小龙,等.榆神矿区基岩顶面土层缺失机理分析及其防治水意义[J].煤田地质与勘探,2018,46(6):102-107.

LI Zhixue,LI Mingpei,SHEN Xiaolong,et al.Genetic analysis of the bedrock top surface soil layer deletion and its significance for water prevention in Yushen mining area[J].Coal Geology & Exploration,2018,46(6):102-107.

[11] 李文平,叶贵钧,张莱,等.陕北榆神府矿区保水采煤工程地质条件研究[J].煤炭学报,2000,25(5):449-454.

LI Wenping,YE Guijun,ZHANG Lai,et al.Study on the engineering geological conditions of protected water resources during coal mining action in Yu-Shen-Fu Mine Area in the North Shanxi Province[J].Journal of China Coal Society,2000,25(5):449-454.

[12] 王启庆,李文平,李涛.陕北生态脆弱区保水采煤地质条件分区类型研究[J].工程地质学报,2014,22(3):515-521.

WANG Qiqing,LI Wenping,LI Tao.Division types of geological conditions at mining with water protection in ecological fragile area of northern shannxi[J].Journal of Engineering Geology,2014,22(3):515-521.

[13] 邓念东,杨佩,林平选,等.榆神矿区保水采煤工程地质条件分区研究[J].煤炭科学技术,2017,45(9):167-174,200.

DENG Niandong,YANG Pei,LIN Pingxuan,et al.Study on zone chart of engineering geological conditions of protected water resources during coal mining in Yushen mining area[J].Coal Science and Technology,2017,45(9):167-174,200.

[14] 赵春虎,虎维岳,靳德武.西部干旱矿区采煤引起潜水损失量的定量评价方法[J].煤炭学报,2017,42(1):169-174.

ZHAO Chunhu,HU Weiyue,JIN Dewu.Method of quantitative evaluation on amount of groundwater inrush from unconfined aquifer caused by mining disturbance in the arid area of Western China[J].Journal of China Coal Society,2017,42(1):169-174.

[15] 王连国,王占盛,黄继辉,等.薄基岩厚风积沙浅埋煤层导水断裂带高度预计[J].采矿与安全工程学报,2012,29(5):607-612.

WANG Lianguo,WANG Zhansheng,HUANG Jihui,et al.Prediction on the height of water-flowing fractured zone for shallow seam covered with thin bedrock and thick windblown sands[J].Journal of Mining & Safety Engineering,2012,29(5):607-612.

[16] 许家林,朱卫兵,王晓振.基于关键层位置的导水断裂带高度预计方法[J].煤炭学报,2012,37(5):762-769.

XU Jialin,ZHU Weibing,WANG Xiaozhen.New method to predict the height of fractured water-conducting zone by location of key strata[J].Journal of China Coal Society,2012,37(5):762-769.

[17] 侯恩科,车晓阳,冯洁,等.榆神府矿区含水层富水特征及保水采煤途径[J].煤炭学报,2019,44(3):813-820.

HOU Enke,CHE Xiaoyang,FENG Jie,et al.Abundance of aquifers in Yushenfu coal field and the measures for water preserved coal mining[J].Journal of China Coal Society,2019,44(3):813-820.

[18] 雷少毅,高亚飞.榆神矿区主要含水层水文地质特征及水化学特征[A].煤炭绿色开发地质保障技术研究—陕西省煤炭学会学术年会(2019)暨第三届“绿色勘查科技论坛”论文集[C].重庆:应急管理出版社,2019:118-127.

[19] 范立民,蒋泽泉.榆神矿区保水采煤的工程地质背景[J].煤田地质与勘探,2004,32(5):32-35.

FAN Limin,JIANG Zequan.Engineering geologic background of coal mining under water-containing condition in Yushen coal mining area[J].Coal Geology and Exploration,2004,32(5):32-35.

[20] LI Wenping,WANG Qiqing,LIU Shiliang,et al.Study on the creep permeability of mining-cracked N2 laterite as the key aquifuge for preserving water resources in Northwestern China[J].International Journal of Coal Science & Technology,2018,5(3):315-327.

[21] 黄庆享.浅埋煤层保水开采岩层控制研究[J].煤炭学报,2017,42(1):50-55.

HUANG Qingxiang.Research on roof control of water conservation mining in shallow seam[J].Journal of China Coal Society,2017,42(1):50-55.

[22] 范立民.保水采煤的科学内涵[J].煤炭学报,2017,42(1):27-35.

FAN Limin.Scientific connotation of water-preserved mining[J].Journal of China Coal Society,2017,42(1):27-35.

[23] 李振宏,董树文,冯胜斌,等.鄂尔多斯盆地中-晚侏罗世构造事件的沉积响应[J].地球学报,2015,36(1):22-30.

LI Zhenhong,DONG Shuwen,FENG Shengbin,et al.Sedimentary response of middle-late jurassic tectonic events in Ordos basin[J].Journal of Geosciences,2015,36(1):22-30.

[24] 杨建.蒙陕接壤区深埋型煤层顶板水文地质及水文地球化学特征[J].煤矿安全,2016,47(10):176-179,183.

YANG Jian.Hydrogeology and hydrogeochemistry of the roof of deep-buried coal seam in the border area between Mongolia and Shaanxi[J].Coal Mine Safety,2016,47(10):176-179,183.

[25] 张晨招.曹家滩煤矿采动裂隙带与矿井涌水数值模拟研究[D].西安:西北大学,2013.

ZHANG Chenzhao.Study on Numerical simulation of mining fracture zone and mine water inflow in Caojiatan Coal Mine[D].Xi’an:Northwest University,2013.

[26] 范立民,贺卫中,仵拨云.榆神矿区综采条件下保水采煤效果分析[J].煤炭技术,2017,36(10):4-5.

FAN Limin,HE Weizhong,WU Boyun.Effect analysis of water-conserving mining based on fully mechanized coal mining in yushen mine area[J].Coal Technology,2017,36(10):4-5.

[27] 师本强.陕北浅埋煤层砂土基型矿区保水开采方法研究[J].采矿与安全工程学报,2011,28(4):548-552.

SHI Benqiang.Research on water-preserved-mining in shallow seam covered with rock soil and sand in northern Shaanxi[J].Journal of Mining and Safety Engineering,2011,28(4):548-552.

[28] 王悦,夏玉成,杜荣军.陕北某井田保水采煤最大采高探讨[J].采矿与安全工程学报,2014,31(4):558-563,568.

WANG Yue,XIA Yucheng,DU Rongjun.Discussion on the maximum mining height of water-retaining coal mining in a minefield in Northern Shaanxi[J].Journal of Mining and Safety Engineering,2014,31(4):558-563,568.

[29] 袁喜东.榆神矿区导水裂隙带发育规律研究[D].西安:西安科技大学,2017.

YUAN Xidong.Study on the development law of water-conducting fracture zone in Yushen mining area[D].Xi’an:Xi’an University of Science and Technology,2017.

[30] 李来源.浅埋深薄基岩厚煤层大采高综采覆岩破坏高度实测研究[J].能源与环保,2017,39(5):206-209.

LI Laiyuan.Study on field measuring of overburden failure height in fully-mechanized coal mining with large mining height in thick coal seam with shallow buried depth and thin bedrock[J].China Energy and Environmental Protection,2017,39(5):206-209.

[31] 妙军科,蒋泽泉.综采工作面导水裂隙带高度的钻孔探测[J].陕西煤炭,2014,33(6):33-36.

MIAO Junke,JIANG Zequan.Borehole detection of the height of water-conducting fracture zone in fully mechanized mining face[J].Shaanxi Coal,2014,33(6):33-36.

[32] 王生全,牛建立,刘洋,等.锦界煤矿水文地质特征与矿井充水危险性预测[J].煤田地质与勘探,2014,42(6):55-58.

WANG Shengquan,NIU Jianli,LIU Yang,et al.Prediction of hydro-geological characteristics and water filling risk in Jinjie mine[J].Coal Geology & Exploration,2014,42(6):55-58.

[33] 郑磊,白海波,马凯.凉水井煤矿顶板导水裂隙发育机理分析[J].煤炭技术,2017,36(1):182-184.

ZHENG Lei,BAI Haibo,MA Kai.Liangshuijing coal mine roof water conduction crack development mechanism analysis[J].Coal Technology,2017,36(1):182-184.

[34] 李涛,王苏健,韩磊,等.生态脆弱矿区松散含水层下采煤保护土层合理厚度[J].煤炭学报,2017,42(1):98-105.

LI Tao,WANG Sujian,HAN Lei,et al.Reasonable thickness of protected loess under loose aquifer in ecologically fragile mining are[J].Journal of China Coal Society,2017,42(1):98-105.

[35] 常金源,李文平,李涛,等.神南矿区煤炭开采水资源漏失量评价分区[J].煤田地质与勘探,2011,39(5):41-45,51.

CHANG Jinyuan,LI Wenping,LI Tao,et al.Zonation of water resources leakage due to coal mining in Shennan mining area[J].Coal Geology & Exploration,2011,39(5):41-45,51.

[36] 赵春虎,靳德武,王皓,等.榆神矿区中深煤层开采覆岩损伤变形与含水层失水模型构建[J].煤炭学报,2019,44(7):2227-2235.

ZHAO Chunhu,JIN Dewu,WANG Hao,et al.Construction and application of overburden damage and aquifer water inrush model in medium-deep buried coal seam mining in Yushen mining area[J].Journal of China Coal Society,2019,44(7):2227-2235.

[37] 赵春虎,董书宁,王皓,等.采煤工作面顶板含水层井下疏水钻孔涌水规律数值分析[J].煤炭学报,2020,45(S1):405-414.

ZHAO Chunhu, DONG Shuning,WANG Hao,et al. Analysis of water inrush from boreholes for drainage of confined aquifer by upward boreholes in underground coal mining face[J].Journal of China Coal Society,2020,45(S1):405-414.