煤炭是我国的基础能源和重要原料,“富煤、缺油、少气”的一次能源赋存条件决定了我国煤炭的主体能源地位在未来相当长一段时间内难以改变。同时,煤炭作为当前最主要的碳排放源,如何为实现碳达峰、碳中和做出煤炭贡献是整个行业迫切需要思考和解决的关键问题。从世界能源供给结构发展进程来看,现代储能技术的快速发展为太阳能、风能、氢能、核能等新能源开发提供了有力支撑,但受间歇性、波动性和安全性的制约,新能源仍然无法完全取代化石能源,对传统能源产业发展急停和盲目快上新能源项目并不是符合当前我国基本国情的正确选择,新能源的发展和国家能源安全仍需要煤炭的保驾护航。

我国煤炭资源禀赋条件差,高含杂低品质煤资源储量丰富[1-2]。随着优质煤炭资源的逐渐消耗,“双碳”背景下的低品质煤洁净高效可持续开发利用已成为保障国家能源安全和煤炭行业高质量发展的战略选择。选煤作为洁净煤技术的基础和源头,不仅可以高效低成本提高煤炭产品质量和后续转化利用效率,也可为选煤厂周边建筑、材料等行业提供部分原料,为煤炭资源全组分协同利用提供条件保障。21世纪以来,我国选煤装备与技术得到快速发展,原煤入洗率超过70%。目前重介质选煤技术的普及与推广使得粗粒低品质煤分选日趋成熟,但细粒低品质煤(低阶/氧化难浮煤、高灰难选煤等)浮选仍面临着严峻挑战,其已成为制约煤炭企业经济效益提升的卡脖子问题,低品质煤泥浮选的基本作用原理与过程强化亟需研究。

目前,低品质煤浮选已成为国际选煤领域的研究热点与难点,据不完全统计,自2010年以来煤炭分选领域公开发表的学术论文中低品质煤浮选主题研究占70%以上。为系统总结和梳理低品质煤泥浮选强化研究现状,笔者从低品质煤泥难浮难选机理(难浮指回收率低,难选指选择性差)、低品质煤泥浮选界面调控及流动强化3个方面进行了系统讨论,并最后提出了未来低品质煤浮选过程强化的新发展方向与技术体系,旨在为低品质煤泥高效提质提供思路与技术借鉴。

1 低品质煤泥难浮难选机理

1.1 低品质难浮煤难浮机理

以褐煤、长焰煤、不黏煤、弱黏煤等低阶煤及氧化煤为代表的低品质难浮煤,其可浮性较差,以煤油或柴油为捕收剂时,吨干煤泥药耗可达10~50 kg,常规浮选流程下生产成本过高[3-5],明晰低品质难浮煤难浮机理是实现其浮选过程强化的前提,也吸引了国内外学者的广泛关注。低品质难浮煤难浮机理的研究及认知过程与颗粒可浮性表征及表面性质检测技术的发展紧密相关,早期主要是采用接触角来评判煤泥的可浮性难易程度,测试精度偏低[6-7]。一般认为煤表面接触角越小,可浮性越差。随着诱导时间、X射线光电子能谱(XPS)、傅里叶红外光谱(FTIR)、反气相色谱(IGC)、核磁共振光谱(NMR)、原子力显微镜(AFM)等新型检测技术在矿物分选领域的运用和浮选胶体化学理论的发展,难浮煤难浮机理的深度揭示成为了可能。

诱导时间是评价颗粒可浮性的重要参数,定义为颗粒-气泡间液膜薄化破裂及三相线铺展所需的总时间,颗粒诱导时间越短则颗粒可浮性越高[8-9],诱导时间结构示意如图1(a)所示。陈松降等[10]借助诱导时间测量仪研究了气泡压缩形变量、接触速度以及气泡直径对神东低阶煤诱导时间的影响规律,发现低阶煤与气泡间诱导时间达数百毫秒。XIA等[11-13]系统研究了纯水及捕收剂作用前后低阶煤、氧化煤的诱导时间变化规律,发现煤油、柴油等常规非极性捕收剂降低难浮煤诱导时间效果有限,在较高的药剂用量下诱导时间仍达数百毫秒,非极性捕收剂对颗粒可浮性改善效果不佳。针对颗粒可浮性精准表征,笔者团队提出了基于颗粒-气泡黏脱附动力学分析的可浮性评价方法,借助磁力搅拌器搅拌观察颗粒在单个浮选气泡表面的黏附行为,并引入振动进一步评价颗粒-气泡矿化气絮体的稳定性全面反映颗粒的可浮性,颗粒气泡黏脱附动力学测量系统主要由电磁激振器、三维位移台、气泡产生单元、工业相机及磁力搅拌装置组成,如图1(b)所示[14-15],研究发现测试所得的黏附速率常数和脱附速率常数与浮选速率常数及接触角具有良好的相关性。

图1 颗粒可浮性表征设备示意

Fig.1 Schematic of the particle floatability characterization equipment

颗粒表面物理化学性质是决定其可浮性的根本因素,XPS、FTIR、IGC等表面检测技术有力促进了低品质难浮煤难浮机理的认知。借助XPS、FTIR等手段对低阶煤表面官能团分布进行了系统测试[16-21],发现低阶煤表面存在丰富的含氧官能团,其主要分为碳氧单键类(包括羟基和醚键)、羧基和羰基3类;对于氧化煤,氧化后表面含氧官能团也明显增多[22-23](图2)。这些含氧官能团与水分子间易形成氢键,难浮煤表面由此形成稳定的水化膜降低颗粒可浮性。NIU等[24]采用IGC分析了煤表面润湿性和表面能组分分布特征,提出以亲水性指数(特定组分占总表面能的比率)评定煤样的可浮性,发现低阶煤表面的高表面能导致颗粒与水分子间的黏附功能增加,可浮性下降。难浮煤表面形貌也是影响难浮煤可浮性的重要因素。SEM、NMR等对氧化煤及低阶煤表面检测结果表明,低阶煤及氧化煤表面形貌粗糙且具有发达的孔隙结构[25-28]。在毛细作用下,孔隙易被水分子填充,在颗粒-气泡黏附过程中孔隙水很难被排出[28-29];与此同时,孔隙结构对小分子量药剂具有很强的吸附作用,致使药耗过高,降低表面孔隙量或换用碳链更长的捕收剂均可有效减缓孔隙对药剂的吸附作用,从而减少浮选药耗[5,30-31]。

图2 煤氧化前后表面XPS C1s分峰图[23]

Fig.2 XPS C1s peaks for coal particle surfaces before and after oxidation[23]

理论化学和计算化学的发展为理解分子/原子尺度上煤与水、药剂及气泡间吸附行为提供了有利工具[32-39]。XIA等[36]通过分子模拟研究了水分子在低阶煤表面的吸附及水化膜的形成机制,发现界面水对低阶煤表面含氧官能团具有强稳定的吸附作用,且水分子在含氧位点上比在含碳位点上更易被吸附,同时在靠近煤表面的坐标处观察到更高的水分子密度,表明煤/水界面水化膜结构的存在。WANG等[35]进一步采用密度泛函理论(DFT)研究了水分子在煤表面的吸附行为,发现水分子中的氧原子更倾向于与煤表面含氧基团中与氧原子相连的氢原子间形成强烈的氢键,含氧基团对水吸附能力为—OOH >—OH>—CHO>—OCH3。ZHANG等[37]通过分子模拟直接研究了不同煤化程度煤表面的接触角变化规律,结果表明煤表面疏水性随煤化程度的增加而先增加后减小,低阶煤表面最为亲水(平衡接触角为43.58°,图3(a)),煤表面接触角与界面氢键数量及煤-水相互作用能直接相关。通常来讲,非极性油捕收剂吸附可显著提升煤表面疏水性,但其对难浮煤的可浮性改善效果有限。XIA等[12]通过模拟研究发现,由于捕收剂分子间疏水相互作用,非极性十二烷分子倾向于在低阶煤-水界面自聚集成油滴,亲水极性位点的存在显著阻碍十二烷油滴的铺展,恶化捕收剂浮选效果(图3(b))。

图3 低阶煤与水滴及非极性油分子相互作用的分子模拟[12,37]

Fig.3 Molecular simulation of low rank coal between water droplet or non-polar oil molecular[12,37]

浮选体系中,颗粒、气泡、油滴间的复杂相互作用直接决定着浮选效率的高低,多尺度表界面力学行为的精准测量进一步深化了对难浮煤难浮机理的认知[40-46]。笔者团队曾利用微牛级分辨率的力测试系统对不同粗糙度煤表面与水滴、气泡间、捕收剂油滴的黏附力进行了直接测试[42],黏附力定义为样品与水滴、气泡间、捕收剂油滴脱离过程中的最大吸引力。煤表面与水滴、气泡、捕收剂油滴间的相互作用力如图4所示,发现随着粗糙度的增加煤与水滴间黏附力逐渐增加(111.70,125.48,136.42 μN),而煤与气泡、油滴间的黏附力则呈现出逐渐减小的趋势,不仅直接证明了粗糙度增加导致煤可浮性恶化的结论,也为系统研究煤炭可浮性变化规律提供了新的技术方法借鉴。

图4 不同粗糙度煤表面与水滴、气泡间、捕收剂油滴的相互作用力测试[42]

Fig.4 Force measurement between water droplet/air bubble/oil droplet and coal surface with different roughness[42]

XING等[43]借助AFM胶体探针技术进一步探索了不同极性捕收剂与新鲜煤/氧化煤表间面的相互作用力(接近过程),采用石蜡和硬脂酸表面替代浮选非极性和极性捕收剂分子,发现氧化煤颗粒与石蜡之间存在单一的排斥力,捕收剂很难驱替难浮煤极性位点吸附的水分子,这与分子模拟结果保持一致。YANG等[44]采用表面覆盖—C17H34—CH3基团的玻璃微珠模拟柴油等烃类捕收剂,借助AFM探究了非极性捕收剂与不同氧化程度煤表面间相互作用,随着煤表面氧化程度的增加,AFM力曲线接近过程中 “跳入”距离逐渐减小直至消失,而退针过程中的黏附力及其“跳出”距离逐渐减少(图5)。XIA等[45-46]通过十一烷硫醇与惰性镀金探针反应获取十一烷修饰的单分子力谱探针,在单分子尺度测试捕收剂分子与不同石墨表面间的皮牛级作用力,结果表明十一烷在接近亲水石墨时会发生排斥现象,而脱附过程中十一烷与亲水石墨表面的黏附力很弱,这主要是亲水石墨表面水化膜所致,可见对于表面亲水的难浮煤,表面存在的水化膜会阻碍非极性烃类油在煤表面的吸附。上述多尺度微纳力学信息的获取为揭示难浮煤难浮机理提供了新的理论视角,复杂浮选溶液化学环境下的低品质煤浮选气液固相间作用仍需进一步系统深化研究。

图5 水环境下模型捕收剂与不同氧化程度煤表面相互作用[44]

Fig.5 Force effects between model flotation collector and coal with different hydrophilicity under water environment[44]

1.2 低品质难选煤难选机理

浮选入料中-0.045 mm粒级灰分一般高于+0.045 mm粒级,这主要是因为部分矸石在煤炭开采及分选过程中泥化形成“高灰细泥”,其主要成分为层状硅酸盐黏土矿物。微细粒黏土在浮选过程中不仅容易随水流非选择性进入浮选泡沫,还会吸附在煤颗粒表面并竞争性吸附浮选药剂,影响颗粒-气泡黏附概率,恶化产品质量的同时降低有用矿物浮选回收率。以焦肥煤等为代表的中高阶煤呈现高灰化,造成生产效率低、泡沫产品灰分高、尾煤脱水困难等问题,甚至导致整个生产系统无法正常运行[47]。目前,关于难选煤难选机理的研究主要是围绕细粒黏土矿物的性质及其浮选行为开展,其中帝国理工大学Cilliers院士、阿尔伯塔大学XU Zhenghe院士、犹他大学Jan Miller院士、武汉理工大学宋少先院士、昆士兰大学PENG Yongjun教授等在此方向做出了突出的学术贡献。

1.2.1 常见黏土矿物结构及其性质

黏土矿物晶体结构由硅氧四面体层(T)和铝氧八面体层(O)按不同比例叠加而成,层内由稳定的共价键连接,而层间由氢键或范德华力连接。按照硅氧四面体和铝氧八面体的组成比例不同,黏土矿物主要可分为高岭石(1∶1)、蒙脱石(2∶1)、伊利石(2∶1)等[48-51]。一般来讲,在浮选溶液环境下黏土矿物表观上荷负电,但实际情况是层状硅酸盐矿物表面荷电具有显著的各向异性特征,其所带电荷可分为构造电荷和表面电荷。构造电荷为永久电荷,主要由矿物晶格类质同象取代和构造缺陷引起而与溶液pH无关,如高价阳离子Si4+或Al3+被低价阳离子Al3+或Fe2+、Mg2+代替产生过剩负电荷(以基面为主)[51-52]。表面电荷为可变电荷,主要是由矿物表面的Si—O断键和Al—O断键的水解作用产生,与溶液pH、离子强度、结晶度等因素有紧密的关系(以边面为主)[51-52]。通常认为,当溶液环境具有高于黏土矿物主边缘位点净质子电荷点的pH时,发生硅醇、铝醇基团的去质子化反应,相反发生质子化[53]。需要指出的是黏土矿物不同晶面的荷电异性无疑增加了其与煤颗粒表面相互作用的复杂程度,传统电泳法Zeta电位测试仅反映黏土颗粒在溶液中的表观电位。

1.2.2 黏土矿物污染精煤机理

关于黏土污染精煤机理研究,目前常见的作用机理有细泥罩盖、水流夹带、机械夹带、连生体颗粒非选择性上浮4种,其中细泥罩盖和水流夹带是最主要的污染机理,对这2者的研究报导也最多。

(1)细泥罩盖机理。

准确判定细泥罩盖发生与否是揭示罩盖机理的前提,但细泥罩盖观点的提出最早却是通过浮选及沉降试验结果推测得到的。ARMOLD等[54-55]通过浮选试验分析指出黏土矿物的种类对细泥罩盖行为起着决定性作用,蒙脱石显著抑制粗粒煤的浮选,但伊利石和高岭石对煤浮选效果影响不大。XU Zhenghe等[56]基于溶液电动电位测试法考察了煤颗粒与不同种类黏土间的罩盖行为,其工作原理如图6所示,利用黏土与煤混合后溶液的Zeta电位峰分布移动情况鉴定2者如何发生相互作用。具体描述为:当混合后溶液Zeta电位峰仍呈现双峰分布且峰位置无明显偏移时,此时煤与黏土在溶液中保持良好的分散状态(图6(b));当混合后煤颗粒Zeta电位峰向黏土电位峰偏移时,说明黏土颗粒开始在煤颗粒表面发生罩盖;当煤表面被黏土完全覆盖时,混合后溶液煤颗粒Zeta电位峰会完全消失。基于此方法研究发现当pH为5、KCl浓度为1 mmol/L时,蒙脱石与煤颗粒混合溶液的Zeta点位呈现单峰分布,证明了体系罩盖行为的存在。但对于高岭石,由于此时煤与高岭石的Zeta电位非常接近,从混合后的溶液电动电位电位无法判断其是否发生罩盖,这也从侧面说明液电动电位测试法研究浮选细泥罩盖具有一定的局限性。也有学者提出除了蒙脱石,高岭石等黏土颗粒也会在煤颗粒表面发生罩盖,如HUSSAIN等[57]研究发现高岭石、绿泥石及伊利石可分别使浮选精煤产率下降18%,20%及28%。ZHANG等[58]的研究也证实了高岭石和蒙脱石在煤表面发生了罩盖,抑制了煤的浮选。上述结论分歧可能是由于不同作者所用的煤样及黏土矿物性质不同导致,这在后续的研究中应该加以关注。

图6 溶液电动电位测试法鉴定细泥罩盖原理[56]

Fig.6 Schematic zeta potential distributions to identify slime coating[56]

近年来,冷冻扫描电镜(Cryo-SEM)、AFM、颗粒在线观测系统(PVM)、石英晶体微天平(QCM-D)等检测技术的成熟与发展为研究细泥罩盖提供了新的技术方法[59-63]。AFM胶体探针技术为煤-黏土颗粒间相互作用力测试提供了可能,PVM和QCM-D则主要适用于低固体浓度或简单理想试验体系。需要特别指出的是,与传统SEM相比Cryo-SEM测试结果具有更好的精确度和可信度,其利用低温液氮可以实现对浮选泡沫或矿浆的原位冷冻,有效避免了传统SEM样品准备过程中颗粒非选择性沉淀对结果产生的误导。笔者所在团队采用Cryo-SEM曾对唐山某高灰难选煤浮选矿浆中的煤粒表面形貌进行观察,如图7所示,结合EDS能谱分析发现黏土颗粒以松散的絮团状罩盖在颗粒表面。

图7 唐山某高灰难选煤矿浆的Cryo-SEM测试

Fig.7 Cryo-SEM images of high-ash refractory coal pulp from Tangshan

对细泥罩盖机理研究,BANDINI等[64]提出了细泥罩盖的静电学假说,指出细泥罩盖是由颗粒Zeta电位的正负和量级决定的。PENG[65]则证实了矿物颗粒间的化学反应也可能导致细泥罩盖的产生。OATS等[66]利用DLVO理论计算了黏土矿物与煤颗粒间相互作用势能,发现影响黏土与煤颗粒凝聚的主要作用力是分子间作用力,因此可通过减弱颗粒间范德华作用力或增强静电斥力来缓解罩盖。笔者团队利用AFM胶体探针技术测试了煤与高岭石/蒙脱石颗粒间的相互作用力,发现去离子水条件下煤-蒙脱石间力曲线存在轻微的跳跃接触现象,而煤-高岭土体系却检测到了排斥力作用;但在Ca2+存在条件下,由于表面双电层被压缩,煤-蒙脱石/高岭石间始终存在引力作用[60-61,67],由此说明煤-黏土颗粒间相互作用势能可以由经典DLVO理论描述,范德华力可能是黏土颗粒罩盖的根本驱动力。需要指出的是目前关于罩盖机理的研究并未考虑黏土矿物表面荷电的各向异性和晶格缺陷等特征,这也将是未来研究细泥罩盖的重点研究方向。

(2)水流夹带机理。

水流夹带指惯性力较小的微细粒矿物跟随水流通过气泡周围的紊流或泡沫普拉托通道进入泡沫层的现象[68-72],是一种伴随浮选发生的非选择性回收过程,且疏水和亲水矿物颗粒均存在不同程度的夹带回收行为。一般认为夹带可分成2个子过程[71-72]:① 颗粒穿越矿浆/气泡界面进入泡沫相;② 颗粒穿越泡沫相普拉托通道进入精矿产品。就微细脉石颗粒为何能穿越矿浆界面目前主要存在3种假说:气泡边界层、气泡尾涡和气泡群理论,如图8所示。

图8 气泡边界层、气泡尾涡和气泡群回收理论示意[72]

Fig.8 Schematic of boundary layer,bubble wake,and bubble swarm theory[72]

颗粒粒度、表面性质、泡沫层结构、矿浆黏度、浮选药剂及浮选设备工况都会影响水流夹带,但颗粒的夹带回收率很大程度上直接取决于浮选产品的水回收率,这主要是因为水是颗粒从矿浆运动到泡沫层的传输介质[73-75]。总体而言,细颗粒通过夹带的回收率与水回收率呈良好的线性关系,而粗颗粒通过夹带的回收率与水的回收率呈抛物线关系。目前,关于脉石颗粒的夹带回收数学模型主要分为3类:基于水回收率计算夹带量模型、直接估算夹带流量模型,泡沫中水回收率和矿浆中分类函数估算夹带量的模型,见表1。

表1 浮选细泥水流夹带回收数学模型

Table 1 Mathematical models of the recovery of slime entrainment in flotation

类型模型公式注释和符号定义基于水回收率计算夹带量模型WARREN模型[76]Rg=egRwRg为脉石回收率; eg为夹带因子,常数;Rw为水回收率Kirjavainen模型[77-79]Ri=1-exp(-PiRw)Ri为i粒级的脉石回收率; Pi为夹带因子CILEK模型[80]Rg=x0.268 4-0.027 6Tf(R-1.031 1w-0.118 6Va)x为矿浆中固体质量分数;Tf为泡沫层厚度;Va为充气速率直接估算夹带流量的模型JOHNSON模型[81]CFi=MGconMGpulpCFi为脉石回收率;MGcon为精矿中单位质量水中的脉石质量; MGpulp为矿浆中单位质量水中的脉石质量BISSHOP模型[82]CFi=1+αγ1+βγα为泡沫中水分排液传递因子;β为固体中水分排液传递因子;γ为泡沫停留时间泡沫中水的回收率和矿浆中分类函数估算夹带量的模型KIRJAVAINEN模型[77-79]P=ω0.7ω0.7+bφη-0.5φm0.5φ-0.4P为夹带因子;ω为水回收速率;m为颗粒质量;η为矿浆黏度;φ为动态形状系数,无单位; b为常数,0.006 94SAVASSI模型[83]ENTi=2exp2.292diζ adj +exp-2.292diζ adj adj=1-ln(1/δ)exp(di/ζ)ENTi为夹带因子;di为i粒级颗粒平均粒度;ζ为夹带参数;δ为排液参数,与粗颗粒的优先排液有关STEVENSON模型[84]R=CTjmaxfεR为单位体积流量回收的脉石量,m/s; CT为泡沫顶层的脉石浓度; jmaxf为柱体中液体的最大表观速度,m/s;ε为泡沫层中液体体积分数。YIANATOS模型[85]EFi=RG,iRwEFi=exp-0.693dp,iδ φ EFi为夹带因子;RG,i为i粒级脉石回收率;dp,i为i粒级颗粒的平均粒度;δ为EFi=0.5时的颗粒平均粒度

2 低品质煤泥浮选界面调控

2.1 难浮煤浮选界面调控

2.1.1 高效浮选捕收剂

难浮煤浮选界面调控的关键科学问题是煤表面疏水性精准调控,因此开发高效浮选捕收剂被认为是一种最有效、最经济的浮选过程强化方法。鉴于难浮煤表面特性与氧化矿有些许类似,油酸、塔尔油、氧化石蜡皂等极性羧酸类氧化矿浮选捕收剂均会对难浮煤浮选有很好的促进作用,特别是在常规非极性烃类油中加入表面活性剂或引入极性基团组分在低阶煤和氧化煤浮选实践中取得了很好的效果。

在非极性烃类油中添加表面活性剂是难浮煤高效捕收剂开发的一种有效途径[4,86-87]。表面活性剂不仅可以有效降低油水界面张力、减小油滴粒径,还可以有效钝化难浮煤表面亲水位点,促进捕收剂在煤表面的吸附铺展。XIA等[12]借助分子动力学模拟研究了非极性捕收剂十二烷中复配阳离子表面活性剂十二烷基三甲基溴化铵(DTAB)在低阶煤表面的吸附行为,发现引入DTAB后,低阶煤表面含氧位点被DTAB极性头基遮蔽,增强了低阶煤表面的疏水性。ZHANG等[88]进一步探索了不同比例的DTAB/柴油混合药剂对低阶煤的捕收效果,指出当DTAB与柴油质量比为1∶2时,精煤产率最大。一方面,DTAB提高了柴油的分散性,促进了柴油在颗粒表面的铺展;XIA等[90]则考察了十二烷与十二烷基苯酚混合物对褐煤浮选的强化作用,发现组合用药比十二烷或十二烷基苯酚单独使用时效果更好。虽然在非极性烃类油中添加表面活性剂是改善低阶煤和氧化煤浮选效果的不错之选,但表面活性剂通常比较昂贵,浮选药剂成本相对较高,与此同时,表面活性剂的引入容易增加对脉石矿物的回收,恶化选择性。

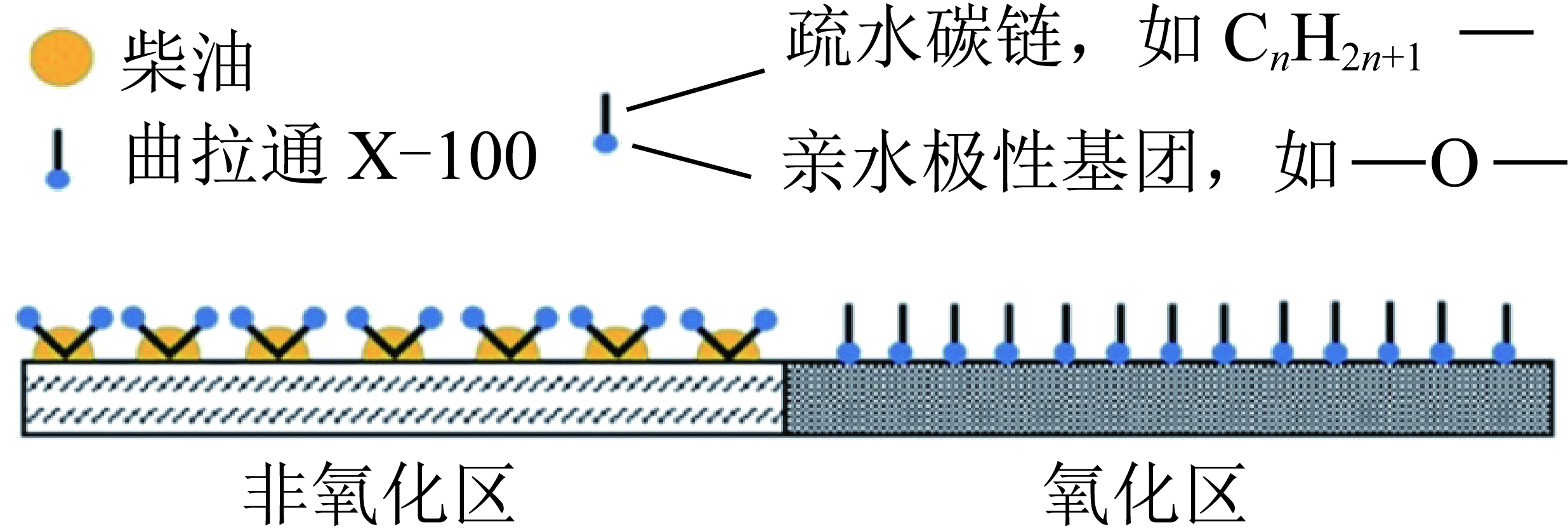

另一方面,DTAB和柴油具有协同作用,提高了煤炭颗粒表面的疏水性和可浮性,增加了颗粒-气泡黏附的稳定性。CHANG等[89]研究了柴油和非离子表面活性剂TX-100复配药剂对氧化煤浮选的影响,揭示该复合捕收剂浮选氧化煤的优良性能源于TX-100对柴油的乳化作用及其与氧化煤表面的亲水位点的吸附(图9)。

图9 柴油和TX-100在氧化煤表面的协同吸附机制[89]

Fig.9 Synergistic adsorption of diesel and TX-100 on the oxidized coal surfaces[89]

在非极性烃类油中引入极性基团、人工复配组合捕收剂及筛选天然油脂类混合物也是开发高效浮选捕收剂的重要方法,如复配柴油、人工氧化柴油、生物柴油、废弃油脂、废弃润滑油、煤焦油等[91-100]。虽然文献中报导的复合药剂种类层出不穷,但此类药剂的界面作用机理均可由JIA等[101]最早提出的吸附模型来解释,即极性组分在氢键作用下与煤表面含氧位点键合,非极性组分在疏水键的作用下与煤表面疏水位点作用,如图10所示。笔者团队通过研究发现药剂中极性官能团与煤亲水位点的氢键可能存在水分子的桥接效应,同时复合药剂协同吸附效应主要源于极性组分对非极性组分吸附的强化作用[102-103]。笔者认为难浮煤浮选捕收剂的开发模式应由传统的经验性试探向精准设计转变,根据煤表面物理化学特性和难浮机理认知开发适配不同难浮煤的浮选捕收剂定向筛选设计技术。

图10 四氢呋喃酯与难浮煤表面的相互作用[101]

Fig.10 Interactions between tetrahydrofuran ester and difficult-to-float coal surface[101]

近年来,在实验室研究进展基础上,难浮煤浮选提质示范工程开始受到选煤厂越来越多的关注。笔者团队王永田教授开发了新型醇醛酸脂复配类捕收剂并在神东布尔台选煤厂建立了16万t/a低阶煤泥浮选脱灰降硫高质化利用示范工程(图11),在捕收剂用量为1.23 kg/t、起泡剂用量为0.41 kg/t药剂制度下,获得了精煤灰分7.31%、尾煤灰分74.24%的良好分选指标,产生了良好的经济、社会与环境效益,坚定了煤炭企业对难浮低品质煤大规模分选提质利用的信心。

图11 神东16万t/a低阶煤泥浮选脱灰降硫高质化利用示范工程

Fig.11 Demonstration project of deashing and desulfuration of low rank coal flotation with 160 000 tons per year in Shendong Mine

2.1.2 表面预处理技术

选前表面预处理对浮选效率的提高也有一定益处,超声预处理是其中一个典型的方法[104-109]。一般认为超声波空化效应可以有效去除煤表面极性羟基、羰基、酚基等含氧基团与罩盖细泥,同时超声机械振动效应能够提高捕收剂在矿浆中的活性及分散特性,强化煤泥分选效果[104]。FENG和ALDRICH[106]发现超声预处理能够显著提高氧化煤浮选回收率及动力学,空化气泡的产生的清洗作用可促使氧化煤可浮性接近甚至超过新鲜煤。CHEN等[109]指出不同的发射频率会导致超声具有不同的强化浮选作用机制(图12):在20~50 kHz低频率范围时,瞬态空化产生的清洗效应占据主导作用;在200~1 000 kHz中等频率范围时,稳态空化产生的微泡在声辐射力诱导下颗粒发生团聚;当频率高于1 000 kHz时,空化效应消失而声辐射力主导颗粒团聚。需要注意的是笔者团队在探究超声处理时间对氧化煤浮选效果的影响中发现,超声波空化过程中产生的羟基自由基会导致新鲜煤表面再次被氧化,从而降低分选效率[104]。

图12 不同频率超声波强化浮选的作用机制[109]

Fig.12 Intensification mechanism of ultrasonic flotation at different frequencies[109]

微波广泛应用于破碎磨矿预处理过程,同样也被证明可以有效强化难浮煤浮选效率,其强化机理主要归功于微波热效应可以有选择性地脱除煤表面的水分和部分含氧基团[110-111]。此外,热解、水热、孔隙压缩等预处理方法同样可以改善煤的可浮性[112-116]。NIU等[112]发现中低温热解可以通过降低烟煤表面含氧官能团含量从而改善其表面疏水性;笔者团队提出水热反应和机械热压预处理也能够显著改变低阶煤的物理化学性质[114-116],在部分脱除含氧基团的同时还可以诱发孔隙结构缩合坍塌,如图13所示,避免药剂向孔隙中的渗透进而提高药剂的改性效率。虽然上述选前预处理方法在实验室试验均取得了良好的强化浮选效果,但其在工业现场的应用均存在较大的局限性。

图13 低阶煤机械热压预处理前后孔隙分布[116]

Fig.13 Distribution of the pores of the low rank coal samples before and after mechanical thermal compression treatment[116]

2.2 难选煤浮选界面调控

细泥罩盖主要由颗粒间微观作用力决定,其界面调控的核心是如何引入颗粒间排斥力增加罩盖能垒;水流夹带则主要由惯性力决定,如何强化黏土颗粒在浮选矿浆中运动的斯托克斯准数则是缓解水流夹带的关键,但需要指出的是细泥在煤泥浮选过程的回收途径往往是多种方式共存。

难选煤浮选界面调控的较常用做法是添加水玻璃、六偏磷酸钠等无机抑制剂,水玻璃水解生成的硅酸胶粒与黏土矿物表面硅质位点发生吸附,形成亲水薄膜的同时也可以增加颗粒表面负电位,达到分散矿泥的目的[117]。但目前的困境是煤表面经常含有未解离的硅质矿物位点,抑制剂在煤表面的非选择性吸附经常导致可燃体回收率大幅度下降,因此工业应用并不成熟,抑制剂与其他药剂的组合使用可能是解决此问题的有效途径。选择性絮凝也是降低黏土矿物回收率的重要方法,微细颗粒在高分子絮凝剂的作用下生成絮体可有效缓解罩盖和夹带[118-120]。梁龙[119]研究了有机絮凝剂聚环氧己烷和无机絮凝剂聚合氯化铝对絮凝浮选的影响,发现聚合氯化铝单独作用下高岭石出现选择性絮凝,从而降低了对浮选精煤的污染。WANG等[120]提出聚乙烯吡咯烷酮可实现难选煤泥中石英和高岭石的强选择性絮凝。但难选煤选择性絮凝降灰工业示范未见报导,究其原因仍是絮凝过程中的杂絮问题难以得到有效控制[118,121]。现场工业实践中,捕收剂、起泡剂种类和比例的调整是控制浮选精煤灰分的最常用做法,但强化效果有限。

3 低品质煤泥浮选流动强化

浮选回收率和选择性不仅受溶液化学条件直接影响,还与矿浆流体力学参数密切相关。流体流动是浮选分离的能量来源,直接影响着颗粒悬浮、气泡药剂的分散以及气液固复杂相间的相互作用[122-124]。本节从流体流动出发探讨低品质煤浮选流动强化的最新研究进展。

3.1 难浮煤浮选流动强化

调浆在促进颗粒-药剂分散及其相互作用方面具有重要作用,研究发现提高调浆过程能量输入使浆体产生强紊流有助于提高煤与捕收剂间的碰撞黏附效率,改善难浮煤表面疏水性和浮选效果[122-124]。王海楠等[122]设计了一种实验室型冲击流浮选调浆装置,矿浆通过入料管形成冲击流撞击冲击板后向冲击板四周发散,形成强紊流混合区,加强颗粒与药剂分散及碰撞,提高了煤浮选回收率。LI等[123]利用自主设计的一种无搅拌流体混合装置并研究了流体强化作用对细粒煤表面改性机理,如图14所示,结果表明流体强化对细粒煤预处理的积极作用主要表现为改善了捕收剂与煤的相互作用,调浆后煤表面疏水基团C—C/C—H含量增加9.75%。

图14 新型流体混合装置示意[123]

Fig.14 Structural diagram of the new type flow mixer[123]

旋流-静态微泡浮选柱是用于细粒矿物回收的高效浮选装置,设备集逆流矿化、旋流矿化、管流矿化为一体,实现了浮选过程的多流态梯级耦合强化。笔者团队比较了旋流静态微泡浮选柱与传统浮选机对微细粒低阶煤泥浮选效果,发现旋流静态微泡浮选柱的高紊流管流矿化单元有效增强了颗粒-气泡碰撞和黏附概率,在相同药剂条件下对微细粒低阶煤泥具有更优的浮选效果[125]。廖寅飞等[126]通过增加浮选柱(床)的管流矿化管长度实现了细粒煤浮选的进一步强化。WANG等[127]提出在管流矿化段增加微涡发生器进一步增加该区域的流场强度,通过数值模拟和浮选试验考察了不同结构涡发生器对流场的影响规律,发现交错排列的微涡发生器可以生成最大的湍流动能、能量耗散率及最优的浮选回收率(图15)。

图15 微涡发生器结构和交错排列的微涡发生器内部速度云图[127]

Fig.15 Geometry of the vortex generator and the velocity distribution with dual arrays[127]

3.2 难选煤浮选流动强化

高剪切强制调浆也是强化难选煤浮选降灰的重要方法。中国矿业大学(北京)马力强教授团队对煤泥浮选强制调浆机理和设备研制进行了开创性研究[128-131],认为流体的高剪切力会剥离煤粒表面附着的异质细泥,使煤粒暴露出新鲜的疏水表面,从而提高非极性烃类捕收剂在其表面的吸附(图16)。基于聚焦光束反射测量等技术系统研究了搅拌强度对煤与黏土颗粒间凝聚与分散行为的影响规律,表明煤与黏土间相互作用遵从DLVO胶体稳定性理论,温和搅拌通过增加颗粒间碰撞概率并提供克服颗粒间能垒的动能加剧了细泥罩盖,而强烈的机械搅拌可以破坏颗粒聚团,使细泥罩盖得到减轻[131]。笔者团队研究也发现对于高灰细泥含量大的调浆过程,需提高调浆过程的剪切率和湍流强度[132-133]。由此开发了折叶开启式涡轮的2段强制搅拌调浆装置,发现仅增加叶轮转速或直径来提高流体剪切和湍流脉动作用有限,两段双层叶轮的强制混合搅拌,可强制实现不同轴向位置矿浆的剪切和混合,实现了对煤粒表面黏土颗粒的剥离和药剂的高效分散。

图16 高强度调浆表面擦洗作用示意[131]

Fig.16 Illustration of surface cleaning in high intensity conditioning flotation[131]

浮选设备结构优化是缓解细泥污染的一个重要方向。一般认为,浮选柱因其较厚的泡沫层较浮选机相比具有更好的分选选择性,受于篇幅限制笔者不再赘述。石焕[134]首次提出了振荡浮选的理念,通过在浮选机槽体安置振荡分离器以解决精煤中矸石夹带污染问题。实验室研究表明:相同分选条件下,与传统浮选机相比,振荡浮选机精煤灰分降低了0.85%。程宏志等[135-136]对振荡浮选降低高灰细泥夹带的机理进行研究,并以实验室模型机为基础运用相似放大原理确定了浮选机结构参数及动力学参数,成功研发了工业化产品FJG-S8型振荡浮选机,精煤灰分相较改造前的机械搅拌式浮选机降低了1.42%。倪超等[137]设计了一种强化重力沉降作用的新型浮选柱,将浮选柱上部结构优化为倾斜柱体,有效强化了精煤泡沫对高灰细泥的脱除能力。

从浮选过程设计的角度看,常规分选设备能量输入保持恒定,忽视了煤泥可浮性随着分选过程非线性变差的特征。笔者所在团队提出了一种基于能量输配的浮选过程设计理念并开发了两段式煤泥分选过程强化方法[138-140],其核心理念是将煤泥分选过程分为快浮段和回收段,快浮段低能量输入快速浮出易浮物料,回收段高能量输入强制回收难浮物料,通过构建越来越强的能量条件来适配物料可浮性在浮选中越来越差的物性变化特征,以实现过程设计与物性特征的最佳耦合(图17,图17中,KⅡ1,KⅡ2,KⅠ分别为在t1时刻两段式分选过程及单段式分选过程物料浮选速率常数的瞬时值)。从黏土浮选行为分析来看,1段低能量输入营造的浮选亏空能量场可以抑制黏土颗粒上浮;2段高能量输入创建的矿浆强力剪切场可强化细泥分散,增加了分选的选择性,两段式柱分选现场试验表明在相近精煤灰分条件下精煤产率可提升5.25%。

图17 两段式分选过程[138]

Fig.17 Illustration of flotation in two-stage separation process[138]

4 低品质煤泥浮选发展方向思考

笔者基于低品质煤泥浮选过程强化研究现状就其未来发展方向做出以下思考:低品质煤难浮难选机理探究方面,复杂浮选溶液化学环境下低品质煤颗粒、黏土晶面、气泡、药剂间的多尺度表界面力作用是深层次揭示其分离机制的关键,原位力学精准表征设备的开发和力来源解析与调控是未来研究的重点;新型高效绿色浮选药剂设计仍将是浮选界面调控的热点方向,打破传统的经验性试探开发模式,根据煤表面基因特性和难浮机理认知,亟需融合单分子力谱测试和大数据分析开发煤炭浮选药剂智能定向筛选设计体系;浮选流动强化方面,如何准确描述浮选流场对分离过程的能量作用机制,更精细化的控制并构建浮选流体动力学环境用来适配物性的非线性变化特征是需要解决的关键科学问题;与此同时,“双碳”背景下的浮选尾煤(煤系固废)资源化利用与规模化消纳也是困扰企业生产的卡脖子问题,应重点关注煤系战略性金属及非金属资源的协同提取、尾煤泥建材化及其在制备土壤改良剂等方面的应用,构建以高值资源化利用为主-规模化消纳为辅的煤系固废综合利用体系;最后将上述研究成果与装备智能感知及生产智能控制有机融合,完成低品质煤浮选界面-流体协同强化全链条智能化示范工程建设,助力我国煤炭行业高质量发展和国家“双碳”战略目标的实现。

5 结 语

基于我国能源供给基本现状和“双碳”战略背景,从低品质煤泥难浮难选机理、浮选界面调控及流动强化3个方面对低品质煤泥浮选研究现状进行了系统讨论。现代分析测试技术和理论计算化学的发展深化了对难浮难选机理的认知,从分子层面研究低阶煤、氧化煤表面官能团和孔隙裂隙对其浮选行为的影响为难浮机理的揭示提供了更基础的理论视角,煤-黏土间相互作用力测试及黏土非选择性上浮行为定量分析为理解难选机理提供了更全面的信息支撑。关于低品质煤泥浮选过程强化,目前难浮煤主要侧重于以高效浮选捕收剂开发为代表的界面调控方法,而难选煤更侧重于利用流体的强化剪切作用实现煤表面黏土的高效剥离,界面与流体的协同强化作用需要引起关注。最后提出了未来低品质煤浮选过程强化的新发展方向与技术体系,主要包括基于多尺度微纳力学解析的低品质煤浮选分离新原理、基于单分子力谱融合深度学习的浮选药剂分子智能定向筛选设计、基于能量精准适配的调浆-浮选流场精细化构建、煤系固废资源化利用与规模化消纳及低品质煤浮选界面-流体协同强化全链条智能化示范工程建设,上述关键科学与技术问题的解决将为我国煤炭行业高质量发展和国家“双碳”战略实施提供新的助力。

[1] 张明旭,樊勇,周敏,等.让低品质煤"脱胎换骨"[J].科技纵览,2016(7):50-52.

ZHANG Mingxu,FAN Yong,ZHOU Min,et al.Thoroughly remould low-quality coal[J].IEEE Spectrum,2016(7):50-52.

[2] 刘炯天,吴立新,吕涛,等.煤炭提质技术与输配方案的战略研究[M].北京:科学出版社,2014.

[3] GUI X,LIU J,CAO Y,et al.Coal preparation technology:Status and development in China[J].Energy & Environment,2015,26(6-7):997-1013.

[4] DEY S.Enhancement in hydrophobicity of low rank coal by surfactants—A critical overview[J].Fuel Processing Technology,2012,94(1):151-158.

[5] ATE OK G,CELIK M S.A new flotation scheme for a difficult-to-float coal using pitch additive in dry grinding[J].Fuel,2000,79(12):1509-1513.

OK G,CELIK M S.A new flotation scheme for a difficult-to-float coal using pitch additive in dry grinding[J].Fuel,2000,79(12):1509-1513.

[6] 谢广元.选矿学.第三版[M].徐州:中国矿业大学出版社,2016.

[7] 吴广玲,宋书宇,樊民强,等.油酸基表面活性剂对氧化煤泥浮选的促进作用研究[J].矿业研究与开发,2014,34(1):55-57,112.

WU Guangling,SONG Shuyu,FAN Minqiang,et al.Experimental study on promoting effect of oleic-acid-based surfactants on oxidized coal slime flotation[J].Mining Research and Development,2014,34(1):55-57,112.

[8] 邢耀文,桂夏辉,曹亦俊,等.颗粒气泡黏附科学——宏观尺度下颗粒气泡黏附研究进展及困境[J].煤炭学报,2019,44(2):582-587.

XING Yaowen,GUI Xiahui,CAO Yijun,et al.Bubble-particle attachment science:Advances and dilemma in bubble-particle attachment on a macroscopic scale[J].Journal of China Coal Society,2019,44(2):582-587.

[9] GU G,XU Z,NANDAKUMAR K,et al.Effects of physical environment on induction time of air-bitumen attachment[J].International Journal of Mineral Processing,2003,69(1-4):235-250.

[10] 陈松降,陶秀祥,杨彦成,等.神东低阶煤浮选诱导时间的实验研究[J].煤炭技术,2016,35(7):319-321.

CHEN Songjiang,TAO Xiuxiang,YANG Yancheng,et al.Experimental study on induction time of Shendong low rank coal[J].Coal Technology,2016,35(7):319-321.

[11] XIA W,LI Y,NGUYEN A V.Improving coal flotation using the mixture of candle soot and hydrocarbon oil as a novel flotation collector[J].Journal of Cleaner Production,2018,195:1183-1189.

[12] XIA Y,ZHANG R,XING Y,et al.Improving the adsorption of oily collector on the surface of low-rank coal during flotation using a cationic surfactant:An experimental and molecular dynamics simulation study[J].Fuel,2019,235:687-695.

[13] XU M,XING Y,CAO Y,et al.Effect of dodecane and oleic acid on the attachment between oxidized coal and bubbles[J].Minerals,2018,8(2):29.

[14] SUN L,XING Y,YANG H,et al.A new experimental approach to evaluate coal particles floatability:Bubble-particle attachment and detachment kinetics[J].ACS Omega,2020,5(27):16733-16738.

[15] YANG H,XING Y,SUN L,et al.Kinetics of bubble-particle attachment and detachment at a single-bubble scale[J].Powder Technology,2020,370:251-258.

[16] XIA Y,WANG L,ZHANG R,et al.Enhancement of flotation response of fine low-rank coal using positively charged microbubbles[J].Fuel,2019,245:505-513.

[17] XIA Y,XING Y,GUI X.Oily collector pre-dispersion for enhanced surface adsorption during fine low-rank coal flotation[J].Journal of Industrial and Engineering Chemistry,2020,82:303-308.

[18] 屈进州.低阶煤活性油泡浮选行为与浮选工艺研究[D].徐州:中国矿业大学,2015.

QU Jinzhou.Research on reactive oily bubble flotation behavior of low rank coal and its flotation technique[D].Xuzhou:China University of Mining and Technology,2015.

[19] 李明,夏阳超,王龙武,等.难浮煤表面性质及亲水性研究[J].矿业研究与开发,2019,39(6):109-113.

LI Ming,XIA Yangchao,WANG Longwu,et al.Study on surface characteristics and hydrophilicity of difficult flotation coal[J].Mining Research and Development,2019,39(6):109-113.

[20] 张锐,夏阳超,谭金龙,等.低阶煤分子碳结构的分析与研究[J].中国煤炭,2018,44(12):88-94,116.

ZHANG Rui,XIA Yangchao,TAN Jinlong,ey al.Analysis and research on low rank coal carbon structure[J].China Coal,2018,44(12):88-94,116.

[21] 陈松降.神东长焰煤的表/界面特征及与活性油泡粘附的作用机制[D].徐州:中国矿业大学,2020.

CHEN Songjiang.Surface/interface characteristics of Shendong long-flame coal and its attachment mechanism with reactive oily bubbles[D].Xuzhou:China University of Mining and Technology,2020.

[22] XIA W,YANG J,LIANG C.Investigation of changes in surface properties of bituminous coal during natural weathering processes by XPS and SEM[J].Applied Surface Science,2014,293:293-298.

[23] XIA W,LI Y.Role of roughness change on wettability of Taixi anthracite coal surface before and after the heating process[J].Energy & Fuels,2016,30:281-284.

[24] NIU C,XIA W,PENG Y.Analysis of coal wettability by inverse gas chromatography and its guidance for coal flotation[J].Fuel,2018,228:290-296.

[25] XU M,XING Y,LI M,et al.Oxidized coal flotation enhanced by adding n-octylamine[J].Energy Sources,Part A:Recovery,Utilization,and Environmental Effects,2018,40(20):2394-2399.

[26] RONG G,XU M,WANG D,et al.Effect of heating oxidation on the surface/interface properties and floatability of anthracite coal[J].Processes,2019,7(6):345.

[27] 王羽玲,夏文成,杨建国,等.无烟煤颗粒表面低温氧化过程研究[J].中国矿业大学学报,2012,41(4):578-581.

WANG Yuling,XIA Wencheng,YANG Jianguo,et al.Low-temperature oxidation process of anthracite particle surface[J].Journal of China University of Mining and Technology,2012,41(4):578-581.

[28] MAO Y,XIA W,PENG Y,et al.Wetting of coal pores characterized by LF-NMR and its relationship to flotation recovery[J].Fuel,2020,272:117737.

[29] 毛玉强,夏文成,彭耀丽,等.孔隙润湿度影响褐煤可浮性的机制[J].煤炭学报,2020,45(S1):451-457.

MAO Yuqiang,XIA Wencheng,PENG Yaoli,et al.Mechanism of pore wetting degree affecting the floatability of lignite[J].Journal of China Coal Society,2020,45(S1):451-457.

[30] SHEN L,WANG C,MIN F,et al.Effect of pores on the flotation of low-rank coal:An experiment and simulation study[J].Fuel,2020,271:117557.

[31] XIA W,ZHOU C,PENG Y.Enhancing flotation cleaning of intruded coal dry-ground with heavy oil[J].Journal of Cleaner Production,2017,161:591-597.

[32] LIU G,YANG X,ZHONG H.Molecular design of flotation collectors:A recent progress[J].Advances in Colloid and Interface Science,2017,246:181-195.

[33] XIA Y,ZHANG R,CAO Y,et al.Role of molecular simulation in understanding the mechanism of low-rank coal flotation:A review[J].Fuel,2020,262:116535.

[34] GAO Z,DING Y,YANG W,et al.DFT study of water adsorption on lignite molecule surface[J].Journal of Molecular Modeling,2017,23(1):27.

[35] WANG C,XING Y,XIA Y,et al.Investigation of interactions between oxygen-containing groups and water molecules on coal surfaces using density functional theory[J].Fuel,2021,287:119556.

[36] XIA Y,YANG Z,XING Y,et al.Molecular simulation study on hydration of low-rank coal particles and formation of hydration film[J].Physicochemical Problems of Mineral Processing,55(2):586-596

[37] ZHANG R,XING Y,XIA Y,et al.New insight into surface wetting of coal with varying coalification degree:An experimental and molecular dynamics simulation study[J].Applied Surface Science,2020,511:145610.

[38] ZHANG Z,YUN T,ZHANG H,et al.Density function study of the interaction of a surface modifier with the oxidized coal surface model[J].ACS Omega,2018,3(11):14585-14591.

[39] ZHANG H,LIU W,XU H,et al.Adsorption behavior of methyl laurate and dodecane on the sub-bituminous coal surface:Molecular dynamics simulation and experimental study[J].Minerals,2019,9(1):30.

[40] XING Y W,GUI X H,PAN L,et al.Recent experimental advances for understanding bubble-particle attachment in flotation[J].Advances in Colloid and Interface Science,2017,246:105-132.

[41] XING Y,XU M,GUI X,et al.The application of atomic force microscopy in mineral flotation[J].Advances in Colloid and Interface Science,2018,256:373-392.

[42] ZHU C,LI G,XING Y,et al.Adhesion forces for water/oil droplet and bubble on coking coal surfaces with different roughness[J].International Journal of Mining Science and Technology,2021,31(4):681-687.

[43] XING Y,LI C,GUI X,et al.Interaction forces between paraffin/stearic acid and fresh/oxidized coal particles measured by atomic force microscopy[J].Energy & Fuels,2017,31(3):3305-3312.

[44] YANG Z,XIA Y,GUO F,et al.Interaction characteristics between diesel and coal with different hydrophilicity:Kinetic and force effects[J].Separation and Purification Technology,2020,232:115958.

[45] XIA Y,XING Y,LI M,et al.Studying interactions between undecane and graphite surfaces by chemical force microscopy and molecular dynamics simulations[J].Fuel,2020,269:117367.

[46] 夏阳超.油性捕收剂在煤炭浮选过程中的多尺度界面作用机制[D].徐州:中国矿业大学,2020.

XIA Yangchao.Multi-scale interfacial mechanism of oily collector in coal flotation[D].Xuzhou:China University of Mining and Technology,2020.

[47] 桂夏辉,程敢,刘炯天,等.异质细泥在煤泥浮选中的过程特征[J].煤炭学报,2012,37(2):301-309.

GUI Xiahui,CHENG Gan,LIU Jiongtian,et al.Process characteristics of heterogeneous fine mud in the coal flotation[J].Journal of China Coal Society,2012,37(2):301-309.

[48] NDLOVU B,FARROKHPAY S,BRADSHAW D.The effect of phyllosilicate minerals on mineral processing industry[J].International Journal of Mineral Processing,2013,125:149-156.

[49] 刘炯天,张明青,曾艳.不同类型黏土对煤泥水中颗粒分散行为的影响[J].中国矿业大学学报,2010,39(1):59-63.

LIU Jiongtian,ZHANG Mingqing,ZENG Yan.Effects of different type clays on the dispersion of fine particles in coal slurry[J].Journal of China University of Mining and Technology,2010,39(1):59-63.

[50] BAI H,LIU Y,ZHAO Y,et al.Effects of clay species on coal flotation under the cationic regulation[J].Chemical Physics Letters,2020,753:137626.

[51] CHEN X,PENG Y.Managing clay minerals in froth flotation—A critical review[J].Mineral Processing and Extractive Metallurgy Review,2018,39(5):289-307.

[52] XU L,TIAN J,WU H,et al.Anisotropic surface chemistry properties and adsorption behavior of silicate mineral crystals[J].Advances in colloid and interface science,2018,256:340-351.

[53] YIN X,GUPTA V,HAO D,et al.Surface charge and wetting characteristics of layered silicate minerals[J].Advances in Colloid & Interface Science,2012:179-182.

[54] ARNOLD B J,APLAN F F.The effect of clay slimes on coal flotation,part I:The nature of the clay[J].International Journal of Mineral Processing,1986,17(3-4):225-242.

[55] ARNOLD B J,APLAN F F.The effect of clay slimes on coal flotation,part II:The role of water quality[J].International Journal of Mineral Processing,1986,17(3-4):243-260.

[56] XU Z H,LIU J J,CHOUNG J W,et al.Electrokinetic study of clay interactions with coal in flotation[J].International Journal of Mineral Processing,2003,68(1-4):183-196.

[57] HUSSAIN S A,DEM,IDOT,et al.Zeta potential measurements on three clays from Turkey and effects of clays on coal flotation[J].Jou Colloid Interface Sci,1996,184(2):535-41.

[58] ZHANG Z,LIU J,XU Z,et al.Effects of clay and calcium ions on coal flotation[J].International Journal of Mining Science and Technology,2013,23(5):689-692.

[59] WANG B,PENG Y J,VINK S.Diagnosis of the surface chemistry effects on fine coal flotation using saline water[J].Energy & Fuels,2013,27(8):4869-4874.

[60] XING Y W,XU X H,GUI X H,et al.Effect of kaolinite and montmorillonite on fine coal flotation[J].Fuel,2017,195:284-289.

[61] XING Y W,GUI X H,CAO Y J.Effect of calcium ion on coal flotation in the presence of kaolinite clay[J].Energy & Fuels 2016,30(2):1517-1523.

[62] NI C,BU X N,XIA W C,et al.Observing slime-coating of fine minerals on the lump coal surface using particle vision and measurement[J].Powder Technology,2018,339:434-439.

[63] BAKHTIARI M,HARBOTTLE D,CURRAN M,et al.Role of caustic addition in bitumen-clay interactions[J].Energy & Fuels,2015,29(1):58-69.

[64] BANDINI P,PRESTIDGE C A,RALSTON J.Colloidal iron oxide slime coatings and galena particle flotation[J].Minerals Engineering,2001,14(5):487-497.

[65] PENG Y J,ZHAO S L.The effect of surface oxidation of copper sulfide minerals on clay slime coating in flotation[J].Minerals Engineering,2011,24(15):1687-1693.

[66] OATS W J,OZDEMIR O,NGUYEN A V.Effect of mechanical and chemical clay removals by hydrocyclone and dispersants on coal flotation[J].Minerals Engineering,2010,23(5):413-419.

[67] GUI X,XING Y,RONG G,et al.Interaction forces between coal and kaolinite particles measured by atomic force microscopy[J].Powder Technology,2016,301:349-355.

[68] LIU D,PENG Y.Reducing the entrainment of clay minerals in flotation using tap and saline water[J].Powder Technology,2014,253:216-222.

[69] 倪超.柱浮选精煤细泥污染形成机理及抑制研究[D].徐州:中国矿业大学,2016.

NI Chao.Understanding and inhibition of fine slime contamination to clean coal in column flotation[D].Xuzhou:China University of Mining and Technology,2016.

[70] 张义,王永田,邢耀文,等.煤泥浮选固体和水的回收特性研究[J].矿山机械,2015,43(9):100-105.

ZHANG Yi,WANG Yongtian,XING Yaowen,et al.Research on recovery characteristics of solid and water during[J].Mining & Processing Equipment,2015,43(9):100-105.

[71] WANG L,PENG Y,RUNGE K.The mechanism responsible for the effect of frothers on the degree of entrainment in laboratory batch flotation[J].Minerals Engineering,2017,100:124-131.

[72] WANG L,PENG Y,RUNGE K,et al.A review of entrainment:Mechanisms,contributing factors and modelling in flotation[J].Minerals Engineering,2015,70:77-91.

[73] ZHENG X,JOHNSON N W,FRANZIDIS J P.Modelling of entrainment in industrial flotation cells:Water recovery and degree of entrainment[J].Minerals Engineering,2006,19(11):1191-1203.

[74] ENGELBRECHT J A,WOODBURN E T.The effects of froth height,aeration rate,and gas precipitation on flotation[J].Journal of the Southern African Institute of Mining and Metallurgy,1975.

[75] LAPLANTE A,KAYA M,SMITH H.The effect of froth on flotation kinetics-A mass transfer approach[J].Mineral Procesing and Extractive Metallurgy Review,1989,5(1-4):147-168.

[76] WARREN L J.Determination of the contributions of true flotation and entrainment in batch flotation tests[J].International Journal of Mineral Processing,1985,14(1):33-44.

[77] KIRJAVAINEN V M.Application of a probability model for the entrainment of hydrophilic particles in froth flotation[J].International Journal of Mineral Processing,1989,27(1-2):63-74.

[78] KIRJAVAINEN V M.Review and analysis of factors controlling the mechanical flotation of gangue minerals[J].International Journal of Mineral Processing,1996,46(1-2):21-34.

[79] KIRJAVAINEN V M.Mathematical model for the entrainment of hydrophilic particles in froth flotation[J].International Journal of Mineral Processing,1992,35(1-2):1-11.

[80] CILEK E C,UMUCU Y.A statistical model for gangue entrainment into froths in flotation of sulphide ores[J].Minerals Engineering,2001,14(9):1055-1066.

[81] JOHNSON N W,MCKEE D J,LYNCH A J.Flotation rates of non-sulphide minerals in chalcopyrite processes[J].Transactions of the American Institute of Mining and Metallurgical Engineers,1974,256:204-226.

[82] BISSHOP J P,WHITE M E.Study of particle entrainment in flotation froths[J].Transactions of the Institution of Mining and Metallurgy,1976,85:191-194.

[83] SAVASSI O N,ALEXANDER D J,FRANZIDIS J P,et al.An empirical model for entrainment in industrial flotation plants[J].Minerals Engineering,1998,11(3):243-256.

[84] STEVENSON P,ATA S,EVANS G M.Convective-dispersive gangue transport in flotation froth[J].Chemical Engineering Science,2007,62(21):5736-5744.

[85] YIANATOS J,CONTRERAS F.Particle entrainment model for industrial flotation cells[J].Powder Technology,2010,197(3):260-267.

[86] WEN B,XIA W,SOKOLOVIC J M.Recent advances in effective collectors for enhancing the flotation of low rank/oxidized coals[J].Powder Technology,2017,319:1-11.

[87] YOU X,HE M,ZHANG M,et al.Molecular dynamics simulations of nonylphenol ethoxylate on the Hatcher model of subbituminous coal surface[J].Powder Technology,2018,332:323-330.

[88] ZHANG R,XIA Y,GUO F,et al.Effect of microemulsion on low-rank coal flotation by mixing DTAB and diesel oil[J].Fuel,2020,260:116321.

[89] CHANG Z,CHEN X,PENG Y.The interaction between diesel and surfactant Triton X-100 and their adsorption on coal surfaces with different degrees of oxidation[J].Powder Technology,2018,142:840-847.

[90] XIA W,NI C,XIE G.Effective flotation of lignite using a mixture of dodecane and 4-dodecylphenol (DDP) as a collector[J].International Journal of Coal Preparation and Utilization,2016,36(5):262-271.

[91] XIA W,YANG Y.Enhancement in flotation of oxidized coal by oxidized diesel oil and grinding pretreatment[J].International Journal of Coal Preparation and Utilization,2013,33(6):257-265.

[92] 郑茜,何琦,丁世豪,等.基于紫外活化的柴油强化低阶煤浮选动力学[J].煤炭学报,2020,45(S2):1003-1011.

ZHENG Xi,HE Qi,DING Shihao,et al.Kinetics of low-rank coal enhanced flotation with diesel oil based on ultraviolet activation[J].Journal of China Coal Society,2020,45(S2):1003-1011.

[93] WANG D,XU M,HE J,et al.Flotation of low rank coal using dodecane after pretreatment by dielectric barrier discharge (DBD) air plasma[J].Fuel,2019,251:543-550.

[94] XIA W,YANG J,LIANG C.Improving oxidized coal flotation using biodiesel as a collector[J].International Journal of Coal Preparation and Utilization,2013,33(4):181-187.

[95] ZHU C,XING Y,XIA Y,et al.Flotation intensification of low-rank coal using a new compound collector[J].Powder Technology,2020,370:197-205.

[96] LI M,XIA Y,ZHANG Y,et al.Mechanism of shale oil as an effective collector for oxidized coal flotation:From bubble-particle attachment and detachment point of view[J].Fuel,2019,255:115885.

[97] XIA Y,YANG Z,ZHANG R,et al.Performance of used lubricating oil as flotation collector for the recovery of clean low-rank coal[J].Fuel,2019,239:717-725.

[98] XU M,XING Y,CAO Y,et al.Waste colza oil used as renewable collector for low rank coal flotation[J].Powder Technology,2019,344:611-616.

[99] ZHANG L,SUN X,LI B,et al.Experimental and molecular dynamics simulation study on the enhancement of low rank coal flotation by mixed collector[J].Fuel,2020,266:117046.

[100] YANG Z,HE Q,CHANG G,et al.Flotation of oxidized coal using coal tar as a new collector[J/OL].Energy Sources,Part A:Recovery,Utilization,and Environmental Effects:1-10.[2020-08-01].DOI:10.1080/15567036.2020.1819916.

[101] JIA R,HARRIS G H,FUERSTENAU D W.An improved class of universal collectors for the flotation of oxidized and/or low-rank coal[J].International Journal of Mineral Processing,2000,58(1):99-118.

[102] GUI X,XING Y,WANG T,et al.Intensification mechanism of oxidized coal flotation by using oxygen-containing collector α-furanacrylic acid[J].Powder Technology,2017,305:109-116.

[103] XIA Y,RONG G,XING Y,et al.Synergistic adsorption of polar and nonpolar reagents on oxygen-containing graphite surfaces:Implications for low-rank coal flotation[J].Journal of Colloid and Interface Science,2019,557:276-281.

[104] XU M,XING Y,GUI X,et al.Effect of ultrasonic pretreatment on oxidized coal flotation[J].Energy & Fuels,2017,31(12):14367-14373.

[105] KANG W,XUN H,HU J.Study of the effect of ultrasonic treatment on the surface composition and the flotation performance of high-sulfur coal[J].Fuel Process Technology,2008,89(12):1337-1344.

[106] FENG D,ALDRICH C.Effect of preconditioning on the flotation of coal[J].Chemical Engineering Communications,2005,192:972-983.

[107] BUTTERMORE W H,SLOMKA B J.The effect of sonic treatment on the flotability of oxidized coal[J].International Journal of Mineral Processing,1991,32(3-4):251-257.

[108] OZKAN S G.Effects of simultaneous ultrasonic treatment on flotation of hard coal slimes[J].Fuel,2012,93:576-580.

[109] CHEN Y,TRUONG V,BU X,et al.A review of effects and applications of ultrasound in mineralflotation[J].Ultrasonics-Sonochemistry,2020,60:1047392.

[110] XIA W,YANG J,LIANG C.Effect of microwave pretreatment on oxidized coal flotation[J].Powder Technology,2013,233:186-189.

[111] OEZBAYOGLU G,DEPCI T,ATAMAN N.Effect of microwave radiation on coal flotation[J].Energy Sources Part A—Recovery Utilization And Environmental Effects,2009,31(6):492-499.

[112] NIU C,XIA W,XIE G.Effect of low-temperature pyrolysis on surface properties of sub-bituminous coal sample and its relationship to flotation response[J].Fuel,2017,208:469-475.

[113] WEN B,XIA W,NIU C.Comparison of pyrolysis and oxidation actions on chemical and physical property of anthracite coal surface[J].Advanced Powder Technology,2020,31:2447-2455.

[114] XU M,GUO F,ZHANG Y,et al.Effect of hydrothermal pretreatment on surface physicochemical properties of lignite and its flotation response[J].Powder Technology,2021,386:81-89.

[115] YANG Z,GUO F,XIA Y,et al.Improved floatability of low-rank coal through surface modification by hydrothermal pretreatment[J].Journal of Cleaner Production,2020,246:119025.

[116] YANG Z,XIA Y,LI M,et al.Effects of pore compression pretreatment on the flotation of low-rank coal[J].Fuel,2019,239:63-69.

[117] YU Y,MA L,CAO M,et al.Slime coatings in froth flotation:A review[J].Minerals Engineering,2017,114:26-36.

[118] 邹文杰.炼焦中煤选择性絮凝-浮选分离研究[D].徐州:中国矿业大学,2014.

ZOU Wenjie.Selective flocculation-flotation separation of coking coal’s middllings[D].Xuzhou:China University of Mining and Technology,2014.

[119] 梁龙.煤泥中黏土矿物的选择性团聚机理研究[D].徐州:中国矿业大学,2017.

LIANG Long.The selective aggregation mechanism of the clay mineral in coal slime[D].Xuzhou:China University of Mining and Technology,2017.

[120] WANG Y,ZHOU W,LI Y,et al.The role of polyvinylpyrrolidone in the selective separation of coal from quartz and kaolinite minerals[J].Colloids and Surfaces A:Physicochemical and Engineering Aspects,2021:126948.

[121] ZOU W,GONG L,HUANG J,et al.Adsorption of hydrophobically modified polyacrylamide P (AM-NaAA-C16DMAAC) on model coal and clay surfaces and the effect on selective flocculation of fine coal[J].Minerals Engineering,2019,142:105887.

[122] 王海楠,杨文清,李丹龙,等.冲击流强化浮选调浆的数值模拟与试验研究[J].煤炭学报,2020,45(S1):443-450.

WANG Hainan,YANG Wenqing,LI Danlong,et al.Numerical simulation and experimental study of impact flow enhancing flotation pulp conditioning[J].Journal of China Coal Society,2020,45(S1):443-450.

[123] LI D,ZHANG C,LI X,et al.Experimental study on the preconditioning of fine coal particles surface modification using a new type flow mixer[J].Fuel,2020,268:117361.

[124] LI D,WANG H,YANG L,et al.Intensification effects of stirred fluid on liquid-solid,gas-liquid and gas-solid interactions in flotation:A review[J].Chemical Engineering & Processing:Process Intensification,2020,15:107943.

[125] XING Y,GUI X,CAO Y,et al.Clean low-rank-coal purification technique combining cyclonic-static microbubble flotation column with collector emulsification[J].Journal of Cleaner Production,2017,153:657-672.

[126] 廖寅飞,刘炯天,李树磊.管段高紊流强化煤泥柱浮选的应用及作用机理[J].煤炭学报,2014,39(3):549-553.

LIAO Yinfei,LIU Jiongtian,LI Shulei.Application and affect mechanism of high turbulence in pipe unit enhancing coal column flotation[J].Journal of China Coal Society,2014,39(3):549-553.

[127] WANG L,WANG Y,YAN X,et al.A numerical study on efficient recovery of fine-grained minerals with vortex generators in pipe flow unit of a cyclonic-static micro bubble flotation column[J].Chemical Engineering Science,2017,158:304-313.

[128] 马力强,韦鲁滨,李吉辉,等.煤泥高效调浆理论研究与应用[J].中国矿业大学学报,2012,41(2):315-319.

MA Liqiang,WEI Lubin,LI Jihui,et al.Study of theory of efficient coal slurry conditioning and its application[J].Journal of China University of Mining and Technology,2012,41(2):315-319.

[129] 马力强,韦鲁滨,江兴华,等.调浆剪切强度对煤泥浮选的影响[J].煤炭学报,2013,38(1):140-144.

MA Liqiang,WEI Lubin,JIANG Xinghua,et al.Effects of shearing strength in slurry conditioning on coal slime flotation[J].Journal of China Coal Society,2013,38(1):140-144.

[130] 李吉辉.高强度浮选调浆过程碰撞速率及流体特性研究[D].北京:中国矿业大学(北京),2015.

LI Jihui.The study on collision probability and fluid characteristic of high intensity conditioning[D].Beijing:China University of Mining and Technology (Beijing),2015.

[131] 于跃先.煤泥浮选颗粒间相互作用及对浮选影响研究[D].北京:中国矿业大学(北京),2018.

YU Yuexian.The study on interparticle interaction and the effect on coal flotation[D].Beijing:China University of Mining and Technology (Beijing),2018.

[132] XING Y,GUI X,LIU J,et al.Flotation behavior of hard-to-separate and high-ash fine coal[J].Physicochemical Problems of Mineral Processing,2016,52:703-717.

[133] 桂夏辉,黄根,袁闯,等.两段强制搅拌调浆的混合特性及对煤泥浮选的影响[J].北京科技大学学报,2013,35(4):423-431.

GUI Xiahui,HUANG Gen,YUAN Chuang,et al.Mixing characteristics of two-stage compulsory stirred pulp-mixing and its influence on fine coal flotation[J].Journal of University of Science and Technology Beijing,2013,35(4):423-431.

[134] 石焕.振荡法改善浮选效果作用机理的研究[D].北京:煤炭科学研究总院,2001.

SHI Huan.Study on the mechanism of improving flotation effect by oscillating flotation[D].Beijing:China Coal Research Institute,2001.

[135] 程宏志,路迈西,石焕,等.振荡法提高浮选选择性的作用机理[J].煤炭学报,2007,32(5):531-534.

CHENG Hongzhi,LU Maixi,SHI Huan,et al.The mechanism of oscillating flotation to improve selectivity[J].Journal of China Coal Society,2007,32(5):531-534.

[136] 程宏志.振荡分离高选择性浮选的研究[J].煤炭科学技术,2005,33(1):53-55.

CHENG Hongzhi.Research on vibration separating high selective floatation[J].Coal Science and Technology,2005,33(1):53-55.

[137] 倪超,谢广元,李彪,等.强化重力沉降作用的浮选柱降灰研究[J].煤炭学报,2014,39(12):2513-2518.

NI Chao,XIE Guangyuan,LI Biao,et al.Enhancement of gravity sedimentation in column flotation to reduce clean coal ash[J].Journal of China Coal Society,2014,39(12):2513-2518.

[138] 桂夏辉.煤泥分选过程强化及两段式分选研究[D].徐州:中国矿业大学,2012.

GUI Xiahui.Two-stage separation and process intensification of fine coal[D].Xuzhou:China University of Mining and Technology,2012.

[139] GUI X H,LIU J T,CAO Y J,et al.Flotation process design based on energy input and distribution[J].Fuel Processing Technology,2014,120:61-70.

[140] GUI X H,CAO Y J,XING Y W,et al.A two-stage process for fine coal flotation intensification[J].Powder Technology,2017,313:361-368.