随着我国浅部煤炭资源的减少,煤矿逐步进入深部开采阶段[1-3]。深部煤层处于“三高一低”的复杂环境中,冲击地压、煤与瓦斯突出等典型煤岩动力灾害在深部开采阶段响应更加剧烈,同时出现了一种兼具这2种灾害部分特征的复合型动力灾害,称为煤岩瓦斯复合动力灾害,严重威胁着人民的生命财产安全[4-7]。充分认识复合动力灾害的孕灾机制是亟待解决的关键科学问题,从力源本质上讲,煤岩瓦斯复合动力灾害的发生是真三轴条件下含瓦斯“煤体-岩体”复合结构(下文称复合煤岩体)应力-渗流耦合失稳灾变过程。掌握灾害孕育过程中含瓦斯复合煤岩体气体渗流特性及力学破坏特征对认识煤岩瓦斯复合动力灾害孕育机理及灾害预测预报具有重要意义。

近些年专家学者在复合煤岩体变形、破坏及瓦斯渗透特性的研究上做了大量工作,在其破坏模式、强度特征、渗流特性以及能量演化规律等方面取得了较大进展。姜耀东等[8]通过研究单轴状态下复合煤岩体应力-应变特征,将组合体失稳过程分为3个阶段。左建平[9-11]、齐庆新[12]、张泽天[13]、秦忠诚[14]、杨磊[15]、CHENG[16]、LI[17]等研究了不同煤岩组合形式对整个复合煤岩系统强度和变形特征的影响。LIU[18-19]、付斌[20]等研究了不同煤与岩单体强度的条件下复合煤岩结构力学性质的变化,发现岩石强度的增大会导致复合结构强度减小。笔者[21-25]系统地研究了不同岩性岩与煤的组合、不同加卸载速率、不同三轴应力状态、不同气体压力条件下的含瓦斯复合煤岩体的声发射规律、力学强度特性和渗流特征,并结合FLAC和CT三维重构技术研究了复合煤岩体破坏-失稳的细观过程。郭东明[26]、曹吉胜[27]、YIN[28]、蔡永博[29]等研究了煤岩倾角对煤岩复合结构在单轴、三轴压缩试验下的变形破坏影响,分析了其宏观变形破坏机制。王晓南[30]、DU[31]、刘汉龙[32]等利用声发射技术分析了复合煤岩体的变形破裂和微震规律。窦林名[33]、赵毅鑫[34]等分别利用电辐射和红外热像技术对复合煤岩试件的破坏前兆特征进行了研究。杨磊[15]、肖晓春[35]、陈光波[36]、ZHANG[37]等研究了不同组合结构和不同应力路径下复合煤岩体力学特性和能量演化规律。朱卓慧[38]、陈岩[39]、SONG[40]等研究了复合煤岩体在循环荷载下力学特性、变形特征和裂纹演化规律。李成杰等[41-44]在考虑到煤岩组合结构交界面过渡效应的情况下用浇筑成型的类煤岩组合体试件测定了单轴压缩条件下不同径向位置处的应力-应变差异,同时采用霍普金森杆研究了在冲击荷载下类煤岩组合体试件的力学和能量演化过程。以上对复合煤岩体的研究均是在单轴或者常规三轴应力状态下进行,然而在实际工程中,复合煤岩结构处于真三轴应力状态,并且现有研究较少考虑瓦斯的影响,因此进行真三轴应力下含瓦斯复合煤岩力学和渗流特性研究显得尤为重要。

针对真三轴应力路径,张晨阳等[45]研究了不同煤岩高度比的试件在真三轴应力下的加卸载应力-应变曲线,得到了煤厚比例对复合煤岩体力学特性的影响规律。尹光志等[46-51]系统地研究了单一岩石、层状复合岩石以及层状复合煤岩体在真三轴应力条件下的破坏准则、应变特性、强度特征和渗流规律,并通过观察人工拼接层状复合煤岩失稳破坏诱发灾害发生的过程,研究了中间主应力及应力的各向异性对复合动力灾害发育过程的影响。上述真三轴试验研究大多关注复合煤岩体这种层状结构特征对试验结果的影响,较少涉及多个不同真三轴路径下复合煤岩体瓦斯渗流、损伤破坏特征的差异性及其破坏机理。而且多采用人工粘结、叠加拼接的复合煤岩试件,忽略了交界面的过渡效应,而人工拼接试件与原生复合煤岩试件在试验结果上存在差异[52]。

鉴于此,笔者采用压制的方式制作整体、有过渡界面的复合煤岩体试件,并进行了多种真三轴应力路径(σ1>σ2>σ3)试验,对含瓦斯复合煤岩体的应力-应变和渗流规律进行研究,分析开采扰动下复合煤岩体界面效应、失稳破坏特征和力学响应机制,揭示真三轴路径下含瓦斯复合煤岩体渗流特性及力学破坏机理,为煤岩瓦斯复合动力灾害发生机理研究和灾害的预测预报提供一定的理论基础。

1 试验装置及方案

1.1 试验装置

试验采用“真三轴气固耦合煤岩渗流试验系统”完成,设备可单独控制3个方向应力加卸载,实现多个路径下的煤岩体力学-渗流试验[53-54],如图1所示。

图1 真三轴气固耦合煤岩渗流试验系统

Fig.1 True triaxial gas-solid coupling experiment system for coal seepage

1.2 试件制备

由于原生复合煤岩体试件难以获取,如何制备出整体、具有过渡界面的复合煤岩体试件替代品就显得尤为重要。笔者在进行复合煤岩体试件制备时,首先以相似理论为基础,按照煤、岩抗压强度之比相似的原则进行材料配比优选,得到了各原材料的最佳配比方案。

袁亮、李术才、许江、WANG Gang等[55-59]通过试验研究发现,以煤粉为骨料,水泥、河沙作为胶结剂压制而成的型煤试件力学参数易于调整,材料容重与孔隙率与原煤接近,吸附特征与原煤相似,能够代替原煤进行实验室试验。故试验中型煤原料选取煤粉、河沙、水泥、蒸馏水,型岩原料选取河沙、水泥、蒸馏水。

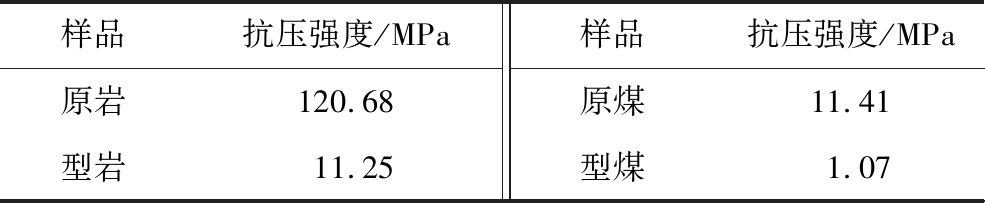

原岩、原煤、煤粉均取自河南省平煤八矿,煤粉为现场取样后,密封送入实验室进行破碎、研磨成粉而成,河沙粒径为0.850~0.425 mm,水泥为425硅酸盐水泥。经大量实验发现,煤粉∶水泥∶河沙∶水质量比为6∶1∶1∶1的煤样以及河沙∶水泥∶水质量比为8∶5∶2的岩样符合试验要求。原煤、原岩以及型煤、型岩抗压强度参数见表1。

表1 岩、煤以及型岩、型煤单轴抗压强度

Table 1 Uniaxial compressive strength of coal,rock, coal briquette and rock briquette samples

样品抗压强度/MPa样品抗压强度/MPa原岩120.68原煤11.41型岩11.25型煤1.07

试件压制时称取河沙1 200 g,水泥750 g,加入300 g蒸馏水搅拌均匀倒入如图2(a)所示模具中铺平,然后称取煤粉900 g、河沙150 g、水泥150 g并加入150 g蒸馏水搅拌均匀倒入模具内的岩样上,在40 MPa加载压力下保压12 h成型后取出,得到如图2(b)所示尺寸为100 mm×100 mm×200 mm的立方体试件,将制备好的复合煤岩体试件放入养护箱中备用。

图2 型煤模具及试件

Fig.2 Moulds and composite coal-rock specimens

1.3 试验应力加载路径

开采扰动下,煤-岩体受力方式不断地发生变化,会出现应力集中、应力卸载以及应力在不同方向上集中和卸载同时存在的状态。为研究复合煤岩结构在真三轴应力路径下的应力-应变及渗流规律,并考虑到试验的安全性,笔者用CO2代替CH4,设置了5种应力路径,图3为应力σ随时间t变化示意。其中,路径1为真三轴应力加载试验,路径2、路径3为真三轴应力复合加卸载试验,路径4、路径5为真三轴中间主应力卸载试验(由于初始应力加载阶段各路径相同,故只在路径1的步骤①、②中进行介绍)。

图3 真三轴应力路径示意

Fig.3 Diagram of true triaxial stress path

路径1:① 同步加载σ1、σ2、σ3至静水压力4 MPa,通入气体压力P为1 MPa的CO2,恒压吸附24 h至饱和;② 吸附饱和后,恒定σ3,以0.05 MPa/s同步加载σ1、σ2至6 MPa,初始应力状态加载完成;③ 保持σ2、σ3恒定,控制σ1以0.05 MPa/s加载至试件破坏,渗流试验同步进行。

路径2:初始应力状态加载完成,以0.05 MPa/s加载σ1至试件强度80%后,保持σ1加载速度不变的同时,以0.03 MPa/s卸载σ2,同步进行σ1加载和σ2卸载至试件破坏,渗流试验同步进行。

路径3:初始应力状态加载完成,以0.05 MPa/s加载σ1至试件强度80%后,保持σ1加载速度不变的同时,以0.01 MPa/s卸载σ2,同步进行σ1加载和σ2卸载至试件破坏,渗流试验同步进行。

路径4:初始应力状态加载完成,以0.05 MPa/s加载σ1至试件强度85%后,保持σ1、σ3恒定,以0.03 MPa/s卸载σ2至试件破坏,渗流试验同步进行。

路径5:初始应力状态加载完成,以0.05 MPa/s加载σ1至试件强度90%后,保持σ1、σ3恒定,以0.01 MPa/s卸载σ2至试件破坏,渗流试验同步进行。

试验认为瓦斯在复合煤岩体试件中的渗流服从达西定律,渗透率计算公式为

(1)

式中,k为试件渗透率,m2;Q为气体流量,m3/s;μ为气体的绝对黏度;L为试件长度,m;A为渗透率有效面积,m2;P′0为标准大气压;P1为入口压力,MPa;P2为出口压力,MPa。

2 试验结果及分析

2.1 试件变形特征

图4为真三轴路径下试件应力-应变曲线,ε1、ε2、ε3分别代表最大主应变、中间主应变和最小主应变,Δσ表示主应力差。对比试件在路径1、路径2和路径4下应变曲线发现,在路径1下试件强度最大,峰值强度时主应力差为34.2 MPa,路径2次之。达到峰值强度时,路径1下试件ε1最大,为0.026 3,路径2下试件ε1为0.025 4、路径4下试件ε1最小,为0.023 8;路径4下试件ε2、ε3最大,分别为-0.005 8和-0.008 1,路径2下次之,为-0.004 6、-0.006 5,路径1下试件的ε2、ε3最小,为-0.002 3、-0.005 2。说明发生破坏时,路径1下试件在最大主应力方向产生了更大的变形;而路径2和4下试件在最大主应力方向发生变形的同时,ε2、ε3方向也会发生较大变形。

图4 真三轴路径下试件全应力-应变曲线

Fig.4 Stress-strain curves of specimens under true triaxial pathes

路径2和路径3为真三轴复合加卸载试验,区别在于试件破坏之前σ2、σ3是否交汇、发生转换。试件在路径3下ε1、ε2、ε3分别为0.025 9、-0.003 9和-0.007 5,相比于路径2,ε1、ε3有所增加,ε2减小。试验初期,2种应力路径下ε2、ε3变化趋势差异不大,应力卸载开始后,在路径2下试件的σ2、σ3之间差值逐渐减小,ε2增速加快,ε3增速减缓,试验后期ε2变化速率开始超过ε3。对比试件在路径4和路径5,恒定σ1、σ3卸载σ2下的应力-应变曲线同样可以得到ε2与ε3速率动态变化的规律。

Mogi-Coulomb准则由于考虑到了中间主应力的影响,常用在描述真三轴路径下煤体、岩体试件的强度特征分析中[60]:

τoct=a+bσm,2

(2)

(3)

(4)

其中,τoct为八面体剪应力,MPa;σm,2为有效正平均应力,MPa。采用Mogi-Coulomb准则,计算得出如图5所示的不同真三轴路径下试件的八面体剪应力和有效平均应力关系。曲线拟合系数达到0.97,拟合度较好,验证了本试验的准确性,也说明Mogi-Coulomb准则能够很好地描述在真三轴路径下复合煤岩体的强度特征。

图5 试件τoct与σm,2拟合结果

Fig.5 Fitting results of τoct and σm,2 of specimens

2.2 渗透率动态变化特征

由于复合煤岩体试件的离散性,试验初始渗透率存在差异,为了方便研究应力路径对试件渗透率的影响规律,以试件初始渗透率为参考值,采用渗透率归一系数w进行分析:

(5)

式中,k0为试件初始渗透率。

图6为真三轴应力路径下复合煤岩体试件渗透率归一系数变化曲线。所有路径中,试件渗透率归一系数均随着ε1的增大呈现出了缓慢降低—急剧增加—趋于平缓的变化趋势。

图6 真三轴路径下试件渗透率归一系数变化规律

Fig.6 Dynamic variation of permeability of specimens under true triaxial stress path

试件在路径1下,渗透率变化范围较小,w最小值为0.07,试验结束后试件w略有增加,为2.01;试件在路径2下,w最小值为0.14,最大值为7.12;试件在路径3下,w最小值为0.37,最大值为4.87;试件在路径4下,w最小值为0.32,最大值为6.02;试件在路径5下,w最小值为0.10,最大值为4.13。

相比于其他路径,试件在真三轴复合加卸载路径下渗透变化范围较大。观察在真三轴复合加卸载路径下、真三轴中间主应力卸载路径下试件渗透率变化规律发现,在σ2、σ3交汇、转换的应力路径中,试件渗透率上升趋势较为显著,表明σ2、σ3的转换对渗透率影响较大。

2.3 试件损伤破坏特征分析

图7显示了含瓦斯复合煤岩体试件在5种真三轴应力路径下的损伤破坏形态,其中σ1-σ2平面和σ1-σ3平面指试件初始应力加载方向所组成的平面。观察发现在σ1-σ2平面上试件的煤体主要以剪切破坏形式为主,剪切裂纹将煤体表面分成多个“V”字形裂纹面,并贯穿了煤体,这与WANG等[61]研究中煤体在真三轴应力路径下呈现的破坏形式相似。

进一步观察损伤破坏形态,在图7(a)所示真三轴加载应力路径下,煤体中的裂纹未由煤体延伸至岩体,而沿着交接面向两边扩展,这与DU等[23]研究中常规三轴加载路径下复合煤岩体破坏形式相似。

图7(b)、(c)为真三轴复合加卸载路径下试件破坏形态。观察图中裂纹特征发现,在σ1-σ2平面上,煤体中同样出现了多条剪切裂纹,并在试件的交界面处交汇,形成“V”字形的裂纹面。剪切裂纹在交汇处转变为张拉裂纹穿过交界面向岩体延伸,岩体发生劈裂破坏。而在σ1-σ3平面上,煤体部分也都发生了剪切破坏,对比岩体部分发现,在路径2发生中间主应力转换路径下岩体破坏,而路径3常规复合加卸载路径下试件σ1-σ3平面的岩体较为完整,未发生破坏。观察岩体中裂纹走向发现,相较于端部,在交界面位置处裂纹开度较大,由此可以推测,裂纹可能首先产生于靠近交界面的岩体中,并向试件端部延伸。

图7 真三轴应力路径下试件损伤破坏形态

Fig.7 Damage patterns of specimens under true triaxial path

将路径2和路径3下试件的岩体进行分离,破坏形态如图8所示。在发生中间主应力发生转换路径下,岩体呈现出“十”字交叉破坏,而路径3中岩体的一面上裂纹贯穿,另一平面较为完整。

图8 岩体损伤破坏面状态

Fig.8 State of rock damage failure surface

图7(d)、(e)为真三轴中间主应力卸载路径下试件损伤破坏形态。观察试件的σ1-σ2平面和σ1-σ3平面发现,与复合加卸载路径下试件破坏形态相似,岩体中的张拉裂纹均是从煤体剪切裂纹交汇处延伸而来。发生中间主应力转换时,试件2个侧面的煤体、岩体均出现破坏,这也揭示了试件在路径2和路径4下出现渗透率增长倍数较大现象的原因。

3 真三轴路径下复合煤岩体强度特性及破坏机理分析

设岩样弹性模量为Er,泊松比为μr,强度为Rr,内摩擦角为φr,煤样弹性模量为Ec,泊松比为μc,强度为Rc,内摩擦角为φc;kr、kc分别为瓦斯在岩样及煤样有效应力系数或Biot系数,其值一般介于0~1,fi为i方向上的煤、岩相互作用力。考虑瓦斯对原生煤岩组合体等效孔隙压力影响以及交界面处相互力的作用,交界面处复合煤岩体受力状态如图9所示。

图9 复合煤岩体交界面微单元受力状态示意

Fig.9 Stress states of microunits at the interface of specimen

其中,煤体微单元部分受力表示为

(6)

复合煤岩体中岩体微单元部分受力表示为

(7)

含瓦斯复合煤岩体中岩体与煤体部分在水平方向上应力-应变本构关系为

(8)

(9)

其中,εl为煤吸附瓦斯膨胀变形量,在复合煤岩试件未产生破坏前,交界面处未产生滑移,试件交界面微单元水平方向各部分应力、应变相等,即εl=0,εir=εic,(i=2,3),联立式(6)~(9),根据静力平衡、M-C屈服准则[62-64],可得

(10)

在已知煤样和岩样抗压强度条件下,令![]() 可得交界面处试件强度为

可得交界面处试件强度为

(11)

(12)

因此,交界面处煤、岩强度变化量Δσ有

(13)

从式(13)可以看出,在复合煤岩体中,交界面处煤体强度大于端部煤体强度,而交界面处岩样强度小于端部岩样强度。观察图7试件破坏形态图发现,端部煤样较为破碎,交界面处岩样出现了大量的微观裂痕,煤样出现的裂纹在交界面处交汇,并穿过交界面向岩样延伸,从试件的宏观破坏形态方面验证了公式的准确性。

在真三轴加载路径试验中,复合煤岩体处于压剪状态,由于煤、岩体力学性质差异和交界面效应的存在,首先会在端部煤体两侧形成剪切裂纹,并逐步向内部延伸,并在交界面处发生交汇,如图10(a)所示。当裂纹强度因子大于交界面煤岩体韧度时,裂纹可穿过交界面向岩体扩展,而σ2和σ3的加载增大了复合煤岩体的强度,煤岩强度比差距较大时,裂纹无法穿过交界面,复合煤岩体表现出只有煤体产生破坏的现象。

图10 试件破裂面示意

Fig.10 Schematic diagram of fracture surface of specimens

在真三轴复合加卸载和真三轴卸载试验中,随着侧向应力的卸载,试件强度降低,裂纹跨界面延伸至岩体。观察试件在路径2和路径4下裂纹状态发现,其与中间主应力的变化有较大关系。试验初期σ2>σ3,在侧应力差导向作用下,裂纹首先出现在σ1-σ2平面,随着σ2的继续卸载,与σ3出现交叉后,σ2<σ3,中间主应力发生转换,致使侧应力差导向作用出现反转,σ1-σ3平面出现裂纹,因此观察到试件的σ1-σ2平面和σ1-σ3平面均出现了宏观破裂,试件破裂过程如图10(b)所示。

在真三轴复合加卸载和真三轴卸载试验中,由于侧压的减小,煤岩体应变出现回弹,同时侧压的卸载降低了试件强度,当侧压卸载到一定程度时,在剪切裂纹交汇处出现张拉裂纹,穿过交界面向岩体延伸。因此,与复合煤岩体试件在常三轴卸载围压和复合加卸载路径下的试验现象不同,在真三轴路径下,试件应力-应变和损伤破坏形态除了与主应力差有关之外,中间主应力的变化也起到了重要作用,其与最小主应力的侧向应力差控制着试件破裂面的扩展方向,尤其在特殊开采导致σ2、σ3发生调整、转换条件下,试件的变形、损伤破坏情况更加复杂。

4 结 论

(1)真三轴路径下复合煤岩体试件强度符合Mogi-Coulomb准则,曲线拟合系数达到0.97,应力路径对试件强度影响较大,试件强度关系为:路径1>路径3>路径2>路径5>路径4,真三轴加载路径下试件强度较大,在相同路径下,当σ2和σ3交汇、转换时,试件强度降低。

(2) 真三轴路径对试件渗透率演化特征影响显著,试验结束后路径2下试件渗透率归一系数最大,达到了7.12,其次为路径4、路径3、路径5、路径1,分别达到了6.02、4.87、4.13、2.01,复合加卸载路径下,试件渗透率变化范围较大,且发生中间主应力转换时,试件渗透率增大倍数较多。

(3) 真三轴加载试验中煤体中出现了大量的剪切裂纹,并在煤岩交界面处交汇,但未穿过交界面延伸至岩体;在真三轴卸载和复合加卸载试验中,剪切裂纹在交汇处转换为张拉裂纹,穿过交界面延伸至岩体,试件中的煤体呈现剪切破坏,岩体呈现劈裂破坏。

(4) 真三轴复合加卸载和真三轴卸载试验中,当σ2和σ3发生交汇、转换时,试件的σ1-σ2平面和σ1-σ3平面上均出现了宏观破裂面,σ2和σ3的侧应力差控制着试件破裂面的扩展方式。

[1] 袁亮.低透高瓦斯煤层群安全开采关键技术研究[J].岩石力学与工程学报,2008,27(7):1370-1379.

YUAN Liang.Key technique of safe mining in low permeability and methane-rich seam group [J].Chinese Journal of Rock Mechanics and Engineering,2008,27(7):1370-1379.

[2] 袁亮.我国深部煤与瓦斯共采战略思考[J].煤炭学报,2016,41(1):1-6.

YUAN Liang.Strategic thinking of simultaneous exploitation of coal and gas in deep mining [J].Journal of China Coal Society,2016,41(1):1-6.

[3] 谢和平,王金华,申宝宏,等.煤炭开采新理念——科学开采与科学产能[J].煤炭学报,2012,37(7):1069-1079.

XIE Heping,WANG Jinhua,SHEN Baohong,et al.New idea of coal mining:Scientific mining and sustainable mining capacity [J].Journal of China Coal Society,2012,37(7):1069-1079.

[4] 谢和平.深部岩体力学与开采理论研究进展[J].煤炭学报,2019,44(5):1283-1305.

XIE Heping.Research review of the state key research development program of China:Deep rock mechanics and mining theory [J].Journal of China Coal Society,2019,44(5):1283-1305.

[5] 姜耀东,潘一山,姜福兴,等.我国煤炭开采中的冲击地压机理和防治[J].煤炭学报,2014,39(2):205-213.

JIANG Yaodong,PAN Yishan,JIANG Fuxing,et al.State of the art review on mechanism and prevention of coal bumps in China [J].Journal of China Coal Society,2014,39(2):205-213.

[6] WANG Kai,DU Feng.Coal-gas compound dynamic disasters in China:A review [J].Process Safety and Environmental Protection,2020,113:1-172.

[7] 潘一山.煤与瓦斯突出、冲击地压复合动力灾害一体化研究[J].煤炭学报,2016,41(1):105-112.

PAN Yishan.Integrated study on compound dynamic disaster of coal-gas outburst and rockburst [J].Journal of China Coal Society,2016,41(1):105-112.

[8] 姜耀东,王涛,宋义敏,等.煤岩组合结构失稳滑动过程的实验研究[J].煤炭学报,2013,38(2):177-182.

JIANG Yaodong,WANG Tao,SONG Yimin,et al.Experimental study on the stick-slip precess of coal-rock composite samples [J].Journal of China Coal Society,2013,38(2):177-182.

[9] 左建平,陈岩,崔凡.不同煤岩组合体力学特性差异及冲击倾向性分析[J].中国矿业大学学报,2018,47(1):81-87.

ZUO Jianping,CHEN Yan,CUI Fan.Investigation on mechanical properties and rock burst tendency of different coal-rock combined bodies [J].Journal of China University of Mining and Technology,2018,47(1):81-87.

[10] 左建平,谢和平,吴爱民,等.深部煤岩单体及组合体的破坏机制与力学特性研究[J].岩石力学与工程学报,2011,30(1):84-92.

ZUO Jianping,XIE Heping,WU Aimin,et al.Investigation on failure mechanisms and mechanical behaviors of deep coal-rock single body and combined body [J].Chinese Journal of Rock Mechanics and Engineering,2011,30(1):84-92.

[11] ZUO Jianping,WANG Zhaofeng,ZHOU Hongwei,et al.Failure behavior of a rock-coal-rock combined body with a weak coal interlayer [J].International Journal of Mining Science and Technology,2013,23(6):907-912.

[12] 齐庆新,高作志,王升.层状煤岩体结构破坏的冲击矿压理论[J].煤矿开采,1998,3(2):14-17

QI Qingxin,GAO Zuozhi,WANG Sheng.The theory of rock burst led by structure failure of bedded coal rock mass [J].Coal Mining Technology,1998,3(2):14-17.

[13] 张泽天,刘建锋,王璐,等.组合方式对煤岩组合体力学特性和破坏特征影响的试验研究[J].煤炭学报,2012,37(10):1677-1681.

ZHANG Zetian,LIU Jianfeng,WANG Lu,et al.Effects of combination mode on mechanical properties and failure characteristics of the coal-rock combinations [J].Journal of China Coal Society,2012,37(10):1677-1681.

[14] 秦忠诚,陈光波,秦琼杰.组合方式对煤岩组合体力学特性和冲击倾向性影响实验研究[J].西安科技大学学报,2017,37(5):655-661.

QIN Zhongcheng,CHEN Guangbo,QIN Qiongjie.Effects of combination mode on mechanical properties and rock burst tendency of the coal-rock combinations [J].Journal of Xi’an University of Science and Technology,2017,37(5):655-661.

[15] 杨磊,高富强,王晓卿.不同强度比组合煤岩的力学响应与能量分区演化规律[J].岩石力学与工程学报,2020,39(S2):3297-3305.

YANG Lei,GAO Fuqiang,WANG Xiaoqing.Mechanical response and energy partition evolution of coal-rock combinations with different strength ratios [J].Chinese Journal of Rock Mechanics and Engineering,2020,39(S2):3297-3305.

[16] CHENG Zhanbo,LI Lianghui,ZHANG Yaning.Laboratory investigation of the mechanical properties of coal-rock combined body [J].Bulletin of Engineering Geology and the Environment,2020,79(4):1947-1958.

[17] 李回贵,李化敏,高保彬.不同煤厚煤岩组合体破裂过程声发射特征研究[J].河南理工大学学报(自然科学版),2021,40(5):30-37.

LI Huigui,LI Huamin,GAO Baobin.Study on acoustic emission characteristics in the process of fracture of coal-rock combination body with different thickness of coal [J].Journal of Henan Polytechnic University(Natural Science),2021,40(5):30-37.

[18] LIU Jie,WANG Enyuan,SONG Dazhao,et al.Effect of rock stren-

gth on failure mode and mechanical behavior of composite samples [J].Arabian Journal of Geosciences,2015,8(7):4527-4539.

[19] 刘杰,王恩元,宋大钊,等.岩石强度对于组合试样力学行为及声发射特性的影响[J].煤炭学报,2014,39(4):685-691

LIU Jie,WANG Enyuan,SONG Dazhao,et al.Effects of rock strength on mechanical behavior and acoustic emission characteristics of samples composed of coal and rock[J].Journal of China Coal Society,2014,39(4):685-691.

[20] 付斌,周宗红,王友新,等.不同煤岩组合体力学特性的数值模拟研究[J].南京理工大学学报,2016,40(4):485-492.

FU Bin,ZHOU Zonghong,WANG Youxin,et al.Numerical simulation of different combination of coal and rock sample mechanics and acoustic emission characteristics[J].Journal of Nanjing University of Science and Technology,2016,40(4):485-492.

[21] WANG Kai,DU Feng.Mechanical properties and permeability evolution in gas bearing coal-rock combination body under triaxial conditions [J].Environmental Earth Sciences,2017,76(24):8151-8159.

[22] WANG Kai,DU Feng.Experimental investigation on mechanical behavior and permeability evolution in coal-rock combined body under unloading conditions[J].Arabian Journal of Geosciences,2019,12(14):422.

[23] DU Feng,WANG Kai.Unstable failure of gas-bearing coal-rock

combination bodies:Insights from physical experiments and numerical simulations [J].Process Safety and Environmental Protection,2019,129:264-279.

[24] DU Feng,WANG Kai,WANG Gongda,et al.The mechanism of damage in gas-bearing coal-rock combination bodies and gas seepage in coals [J].Energy Sources,Part A:Recovery,Utilization,and Environmental Effects,2021,43(10):1181-1201.

[25] 杜锋,王凯,董香栾.基于CT三维重构的煤岩组合体损伤破坏数值模拟研究[J].煤炭学报,2021,46(S1):253-262.

DU Feng,WANG Kai,DONG Xiangluan.Numerical simulation of damage and failure of coal-rock combination based on CT three-dimensional reconstruction[J].Journal of China Coal Society,2021,46(S1):253-262.

[26] 郭东明,左建平,张毅,等.不同倾角组合煤岩体的强度与破坏机制研究[J].岩土力学,2011,32(5):1333-1339.

GUO Dongming,ZUO Jianping,ZHANG Yi,et al.Research on strength and failure mechanism of deep coal-rock combination bodies of different inclined angles [J].Rock and Soil Mechanics,2011,32(5):1333-1339.

[27] 曹吉胜,戴前伟,周岩,等.考虑界面倾角及分形特性的组合煤岩体强度及破坏机制分析[J].中南大学学报(自然科学版),2018,49(1):175-182.

CAO Jisheng,DAI Qianwei,ZHOU Yan,et al.Failure mechanism and strength of coal-rock combination bodies considering dip angles and fractal characteristics of interface[J].Journal of Central South University(Science and Technology),2018,49(1):175-182.

[28] YIN Dawei,CHEN Shaojie,LIU Xingquan,et al.Effect of joint angle in coal on failure mechanical behaviour of roof rock-coal combined body[J].Quarterly Journal of Engineering Geology and Hydrogeology,2018,51(2):202.

[29] 蔡永博.受载含瓦斯原生煤岩组合体损伤渗流演化特性及应用研究[D].北京:中国矿业大学(北京),2021.

CAI Yongbo.Study on damage and permeability evolution characteristics of loaded gas bearing primary coal-rock combination bodies and its application[D].Beijing:China University of Mining Science and Technology-Beijing,2021.

[30] 王晓南,陆菜平,薛俊华,等.煤岩组合体冲击破坏的声发射及微震效应规律试验研究[J].岩土力学,2013,34(9):2569-2575.

WANG Xiaonan,LU Caiping,XUE Junhua,et al.Experimental research on rules of acoustic emission and microseismic effects of burst failure of compound coal-rock samples[J].Rock and Soil Mechanics,2013,34(9):2569-2575.

[31] WANG Kai,DU Feng,WANG Gongda,et al.Investigation of the acoustic emission characteristics during deformation and failure of gas-bearing coal-rock combined bodies [J].Journal of Loss Prevention in the Process Industries,2018,55:253-266.

[32] 刘汉龙,金林森,姜德义,等.煤与砂岩复合岩声发射统计效应的试验与最大似然理论[J].煤炭学报,2019,44(5):1544-1551.

LIU Hanlong,JIN Linsen,JIANG Deyi,et al.Experimental and maximum likelihood theory on acoustic emission statistic effect of coal-sandstone composite rock[J].Journal of China Coal Society,2019,44(5):1544-1551.

[33] 窦林名,田京城,陆菜平,等.组合煤岩冲击破坏电磁辐射规律研究[J].岩石力学与工程学报,2005,24(19):3541-3544.

DOU Linming,TIAN Jingcheng,LU Caiping,et al.Research on electromagnetic radiation rules of composed coal-rock burst failure [J].Chinese Journal of Rock Mechanics and Engineering,2005,24(19):3541-3544.

[34] 赵毅鑫,姜耀东,祝捷,等.煤岩组合体变形破坏前兆信息的试验研究[J].岩石力学与工程学报,2008,27(2) :339-346.

ZHAO Yixin,JIANG Yaodong,ZHU Jie,et al.Experimental studyon precursory information of deformations of coal-rock composite samples before failure [J].Chinese Journal of Rock Mechanics and Engineering,2008,27(2):339-346.

[35] 肖晓春,樊玉峰,吴迪,等.组合煤岩破坏过程能量耗散特征及冲击危险评价[J].岩土力学,2019,40(11):4203-4212,4219.

XIAO Xiaochun,FAN Yufeng,WU Di,et al.Energy dissipation feature and rock burst risk assessment in coal-rock combinations [J].Rock and Soil Mechanics,2019,40(11):4203-4212,4219.

[36] 陈光波,秦忠诚,张国华,等.受载煤岩组合体破坏前能量分布规律[J].岩土力学,2020,41(6):2021-2033.

CHEN Guangbo,QIN Zhongcheng,ZHANG Guohua,et al.Law of energy distribution before failure of a loaded coal-rock combined body [J].Rock and Soil Mechanics,2020,41(6):2021-2033.

[37] ZHANG Heng,LU Caiping,LIU Bin,et al.Numerical investigation on crack development and energy evolution of stressed coal-rock combination[J].International Journal of Rock Mechanics and Mining Sciences,2020,133:104417.

[38] 陈岩,左建平,宋洪强,等.煤岩组合体循环加卸载变形及裂纹演化规律研究[J].采矿与安全工程学报,2018,35(4):826-833.

CHEN Yan,ZUO Jianping,SONG Hongqiang,et al.Deformation and crack evolution of coal-rock combined body under cyclic loading-unloading effects [J].Journal of Mining &Safety Engineering,2018,35(4):826-833.

[39] SONG Shilin,LIU Xuesheng,TAN Yunliang,et al.Study on failure modes and energy evolution of coal-rock combination under cyclic loading [J].Shock and Vibration,2020,2020:1-16.

[40] 朱卓慧,冯涛,宫凤强,等.煤岩组合体分级循环加卸载力学特性的实验研究[J].中南大学学报(自然科学版),2016,47(7):2469-2475.

ZHU Zhuohui,FENG Tao,GONG Fengqiang,et al.Experimental research of mechanical properties on grading cycle loading-unloading behavior of coal-rock combination bodies at different stress levels[J].Journal of Central South University(Science and Technology),2016,47(7):2469-2475.

[41] 李成杰,徐颖,张宇婷,等.冲击荷载下裂隙类煤岩组合体能量演化与分形特征研究[J].岩石力学与工程学报,2019,38(11):2231-2241.

LI Chengjie,XU Ying,ZHANG Yuting,et al.Study on energy evolution and fractal characteristics of cracked coal-rock-like combined body under impact loading [J].Chinese Journal of Rock Mechanics and Engineering,2019,38(11):2231-2241.

[42] 李成杰,徐颖,冯明明,等.单轴荷载下类煤岩组合体变形规律及破坏机理[J].煤炭学报,2020,45(5):1773-1782.

LI Chengjie,XU Ying,FENG Mingming,et al.Deformation law and failure mechanism of coal-rock-like combined body under uniaxial loading[J].Journal of China Coal Society,2020,45(5):1773-1782.

[43] 李成杰,徐颖,叶洲元.冲击荷载下类煤岩组合体能量耗散与破碎特性分析[J].岩土工程学报,2020,42(5):981-988.

LI Chengjie,XU Ying,YE Zhouyuan.Energy dissipation and crushing characteristics of coal-rock-like combined body under impact loading [J].Chinese Journal of Geotechnical Engineering,2020,42(5):981-988.

[44] LI Chengjie,XU Ying,CHEN Peiyuan,et al.Dynamic mechanical properties and fragment fractal characteristics of fractured coal-rock-like combined bodies in split hopkinson pressure bar tests [J].Natural Resources Research,2020,29(1):3179-3195.

[45] 张晨阳,潘俊锋,夏永学,等.真三轴加卸载条件下组合煤岩冲击破坏特征研究[J].岩石力学与工程学报,2020,39(8):1522-1533.

ZHANG Chenyang,PAN Junfeng,XIA Yongxue,et al.Research on impact failure characteristics of coal-rock combination bodies under true triaxial loading and unloading conditions [J].Chinese Journal of Rock Mechanics and Engineering,2020,39(8):1522-1533.

[46] 尹光志,李星,鲁俊,等.真三轴应力条件下层状复合岩石破坏准则[J].岩石力学与工程学报,2017,36(2):261-269.

YIN Guangzhi,LI Xing,LU Jun,et al.A failure criterion for layered composite rock under true triaxial stress conditions [J].Chinese Journal of Rock Mechanics and Engineering,2017,36(2):261-269.

[47] LU Jun,YIN Guanbgzhi,DENG Bozhi,et al.Permeability characteristics of layered composite coal-rock under true triaxial stress conditions [J].Journal of Natural Gas Science and Engineering,2019,66:60-76.

[48] 鲁俊,尹光志,高恒,等.真三轴加载条件下含瓦斯煤体复合动力灾害及钻孔卸压试验研究[J].煤炭学报,2020,45(5):1812-1823.

LU Jun,YIN Guangzhi,GAO Heng,et al.Experimental study on compound dynamic disaster and drilling pressure relief of gas-bearing coal under true triaxial loading[J].Journal of China Coal Society,2020,45(5):1812-1823.

[49] LU Jun,YIN Guangzhi,ZHANG Dongming,et al.True triaxial str-ength and failure characteristics of cubic coal and sandstone under different loading paths [J].International Journal of Rock Mechanics and Mining Science,2020,134(10),104439.

[50] LU Jun,HUANG Gun,GAO Heng,et al.Mechanical properties of layered composite coal-rock subjected to true triaxial stress [J].Rock Mechanics and Rock Engineering,2020,53(9):4117-4138.

[51] LU Jun,YIN Guangzhi,GAO Heng,et al.Truetriaxial experimental study of disturbed compound dynamic disaster in deep underground coal mine [J].Rock Mechanics and Rock Engineering,2020,53(5):2347-2364.

[52] 蔡永博,王凯,徐超.煤岩单体及原生组合体变形损伤特性对比试验研究[J].矿业科学学报,2020,5(3):278-283.

CAI Yongbo,WANG Kai,XU Chao.Comparative experimental study on deformation and damage characteristics of single coal rock and primary coal-rock combination [J].Journal of Mining Science and Technology,2020,5(3):278-283.

[53] 李文鑫,王刚,杜文州,等.真三轴气固耦合煤体渗流试验系统的研制及应用[J].岩土力学,2016,37(7):2109-2118.

LI Wenxin,WANG Gang,DU Wenzhou,et al.Development and application of a true triaxial gas-solid coupling testing system for coal seepage [J].Rock and Soil Mechanics,2016,37(7):2109-2118.

[54] WANG Gang,LIU Zhiyuan,HU Yanwei,et al.Influence of gas migration on permeability of soft coalbed methane reservoirs under true triaxial stress conditions [J].Royal Society Open Science 2019,6(10):190892.

[55] 王汉鹏,张庆贺,袁亮,等.含瓦斯煤相似材料研制及其突出试验应用[J],岩土力学,2015,36(6):1666-1682.

WANG Hanpeng,ZHANG Qinghe,YUAN Liang,et al.Development of a similar material for methane-bearing coal and its application to outburst experiment [J].Rock and Soil Mechanics,2015,36(6):1666-1682.

[56] 李术才,周毅,李利平,等.地下工程流-固耦合模型试验新型相似材料的研制及应用[J] 岩石力学与工程学报,2012,31(6):1128-1137.

LI Shucai,ZHOU Yi,LI Liping,et al.Development and applction of a new similar material for underground engineering fluid-solid coupling model test [J].Chinese Journal of Rock Mechanics and Engineering,2012,31(6):1128-1137.

[57] 尹光志,赵洪宝,许江,等.煤与瓦斯突出模拟试验研究[J].岩石力学与工程学报,2009,28(8):1674-1680.

YIN Guangzhi,ZHAO Hongbao,XU Jiang,et al.Experimental study of simulation of coal and gas outburst [J].Chinese Journal of Rock Mechanics and Engineering,2009,28(8):1674-1680.

[58] 许江,陶云奇,尹光志,等.煤与瓦斯突出模拟试验台的研制与应用[J].岩石力学与工程学报,2008,27(11):2354-2362.

XU Jiang,TAO Yunqi,YIN Guangzhi,et al.Development and application of coal and gas outburst simulation test device [J].Chnese Journal of Rock Mechanics and Engineering,2008,27(11):2354-2362.

[59] WANG Gang,LI Wenxin,WANG Pengfei,et al.Deformation and

gas flow characteristics of coal-like materials under triaxial stress conditions [J].International Journal of Rock Mechanics &Mining Sciences,2016,91:72-80.

[60] MOGI K.Experimental rock mechanics [M].London:Taylor and Francis Group,2007:51-66.

[61] 王刚,刘志远,王鹏飞,等.考虑瓦斯吸附作用的真三轴煤体剪切渗流特性试验研究[J].采矿与安全工程学报,2020,36(5):1061-1069.

WANG Gang,LIU Zhiyuan,WANG Pengfei,et al.Experimental study on shear seepage characteristics of true triaxial coal body under the consideration of gas adsorption[J].Journal of Mining and Safety Engineering,2020,36(5):1061-1069.

[62] 谭学术,鲜学福,郑道访,等.复合岩体力学理论及其应用[M].北京:煤炭工业出版社,1994:63-71.

[63] ZHAO Zenghui,WANG Weiming,DAI Chunquan,et al.Failure ch-aracteristics of three-body model composed of rock and coal with different strength and stiffness [J].Transactions of Nonferrous Metals Society of China,2014,24(5):1538-1546.

[64] 陈绍杰,尹大伟,张保良,等.顶板-煤柱结构体力学特性及其渐进破坏机制研究[J].岩石力学与工程学报,2017,36(7):1588-1597.

CHEN Shaojie,YIN Dawei,ZHANG Baoliang,et al.Mechanical characteristics and progressive failure mechanism of roof-coal pillar structure [J].Chinese Journal of Rock Mechanics and Engineering,2017,36(7):1588-1597.