Simulation study on in-situ pyrolysis behavior of tar-rich coal under overburden stress

-

摘要:

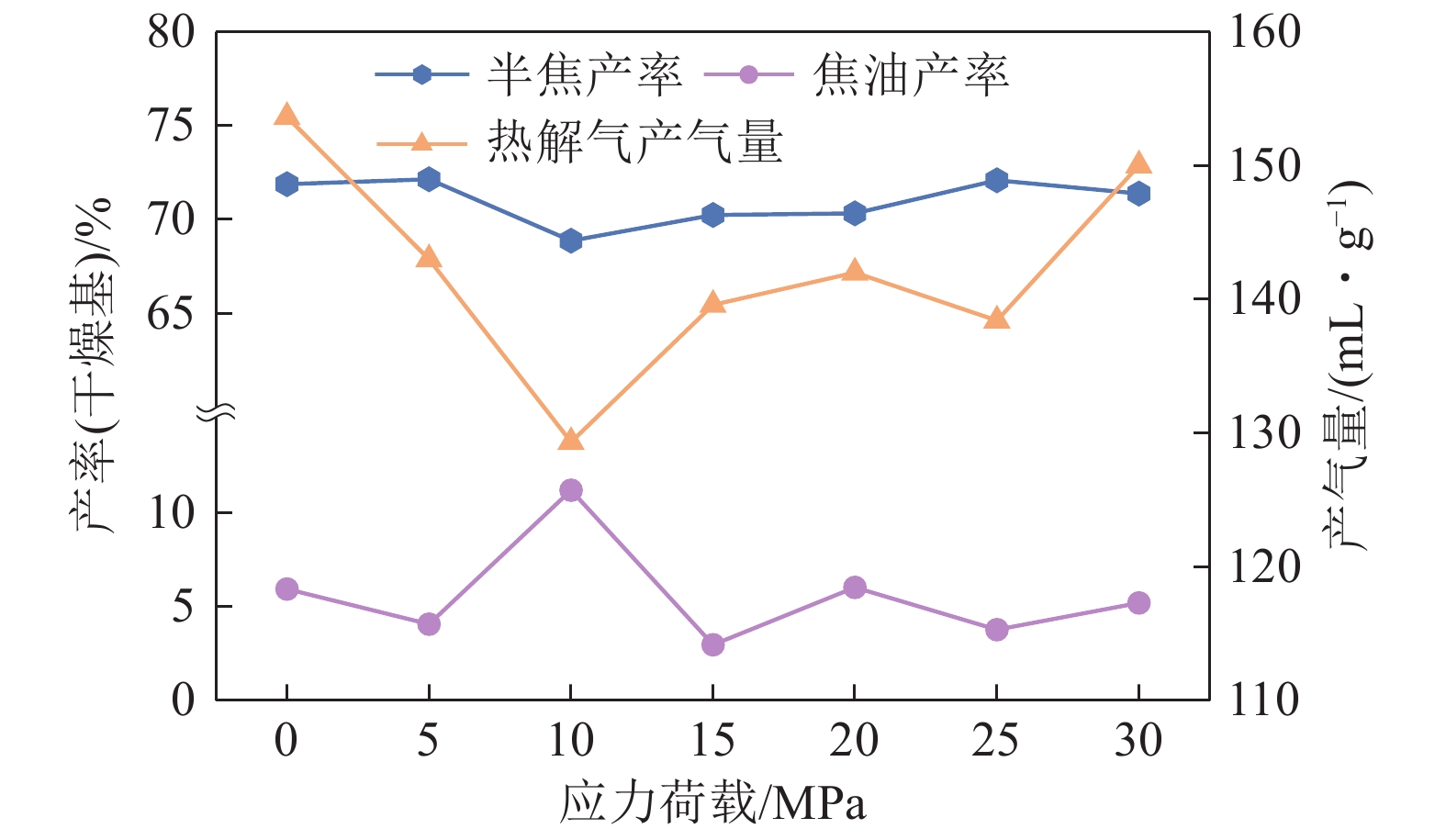

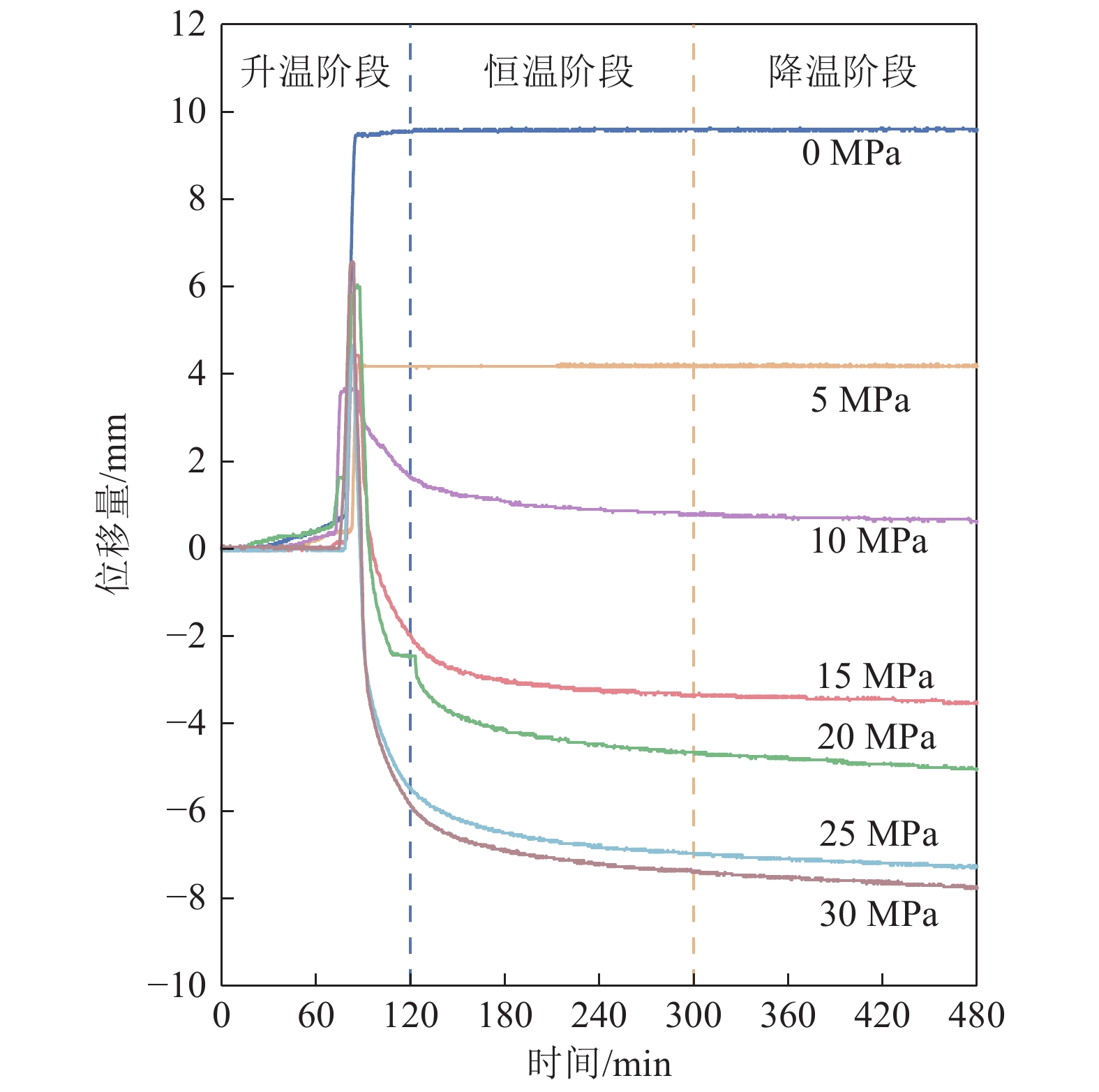

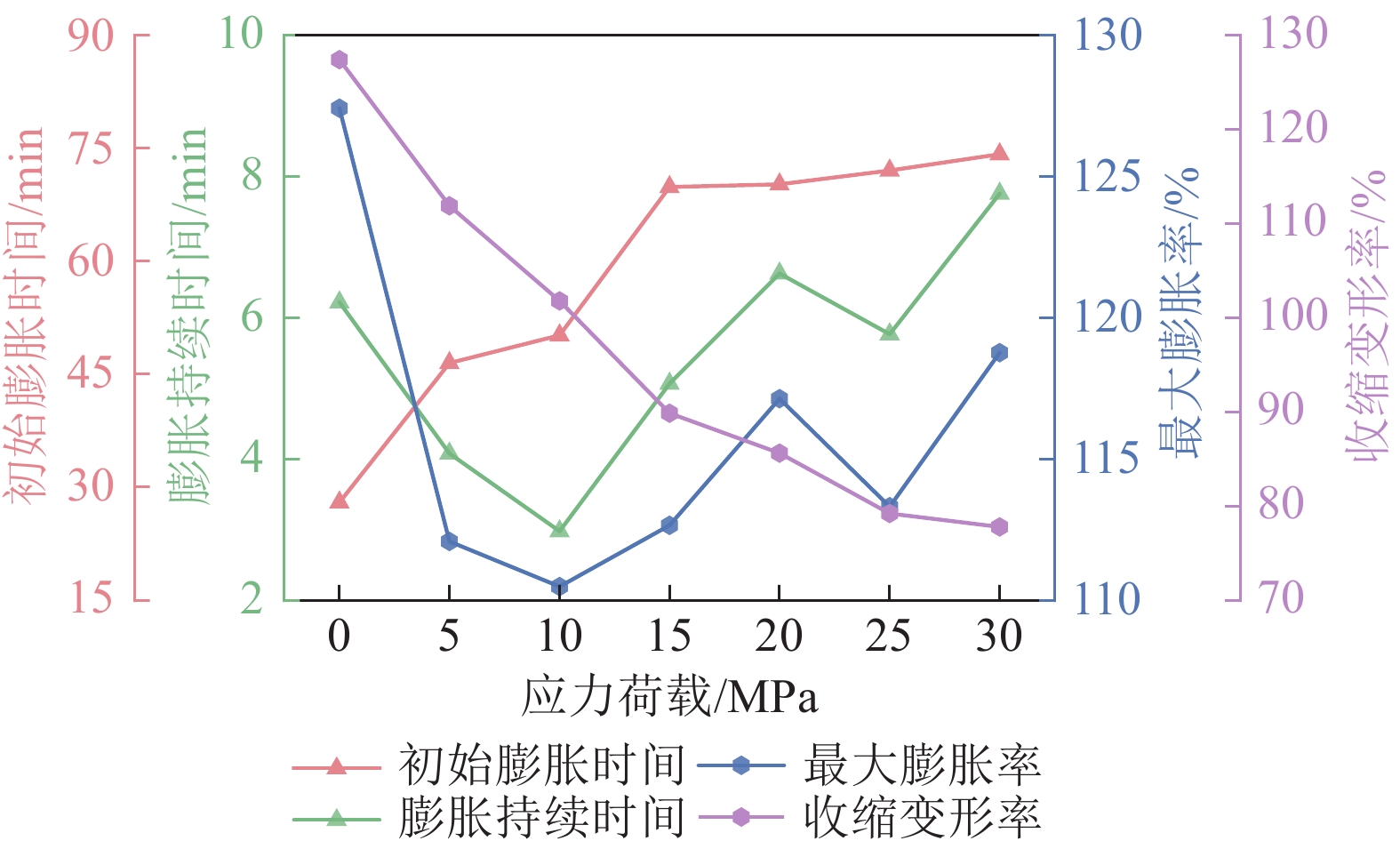

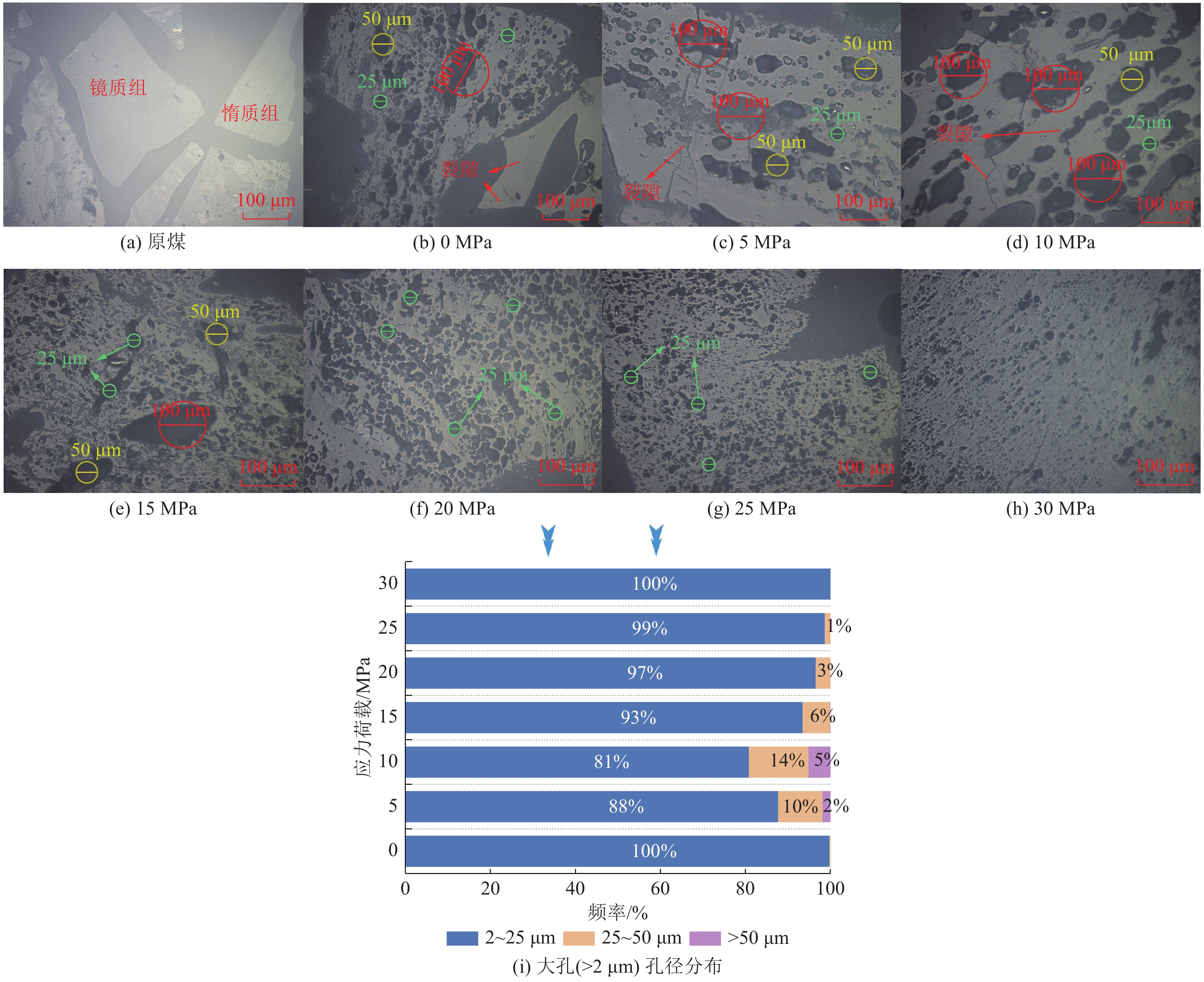

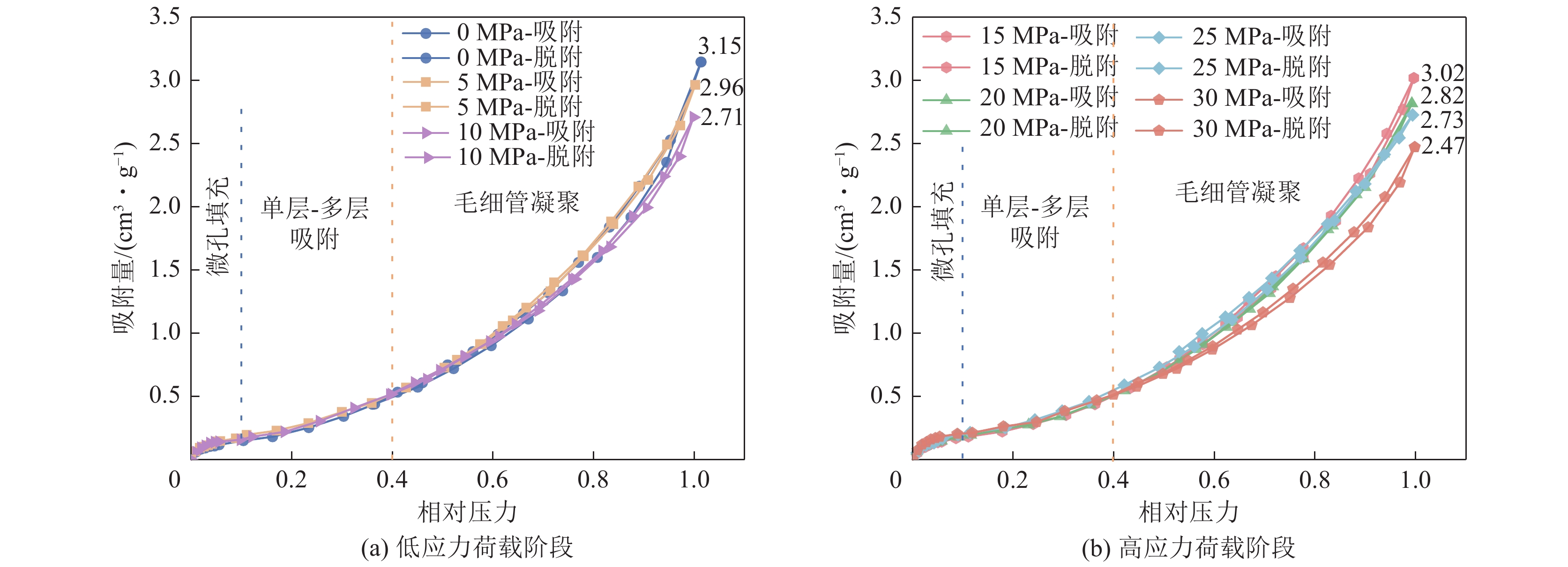

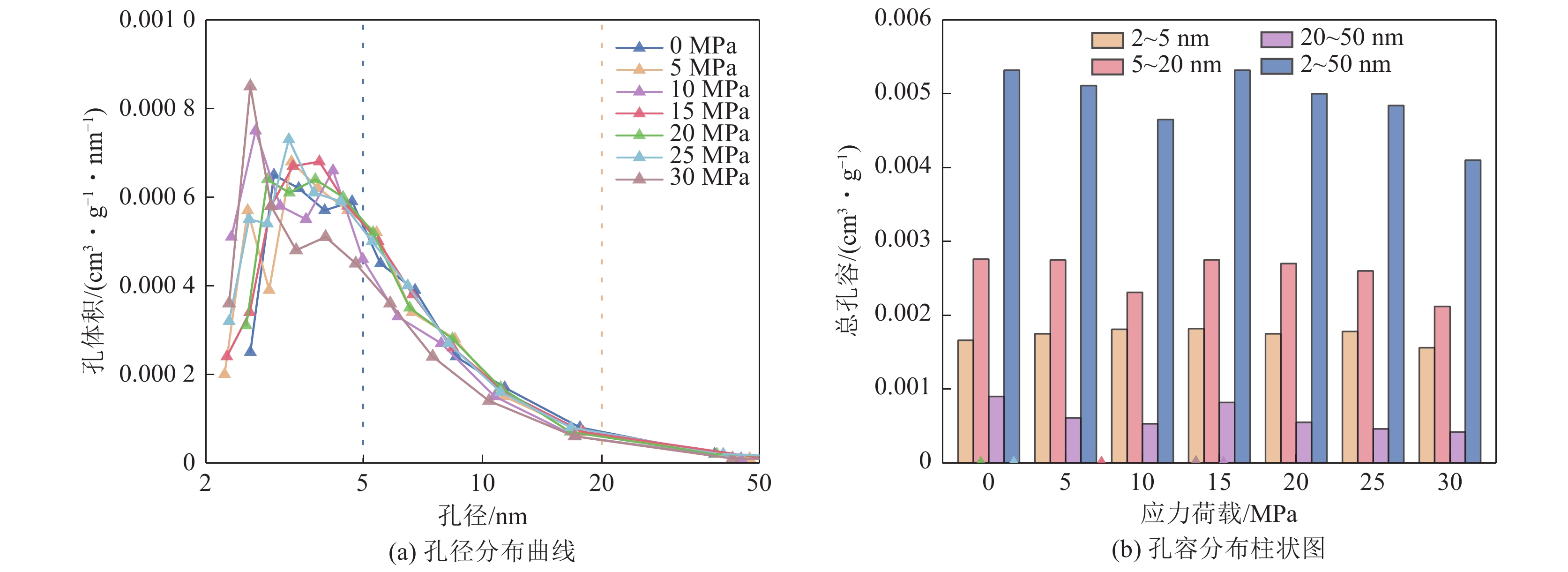

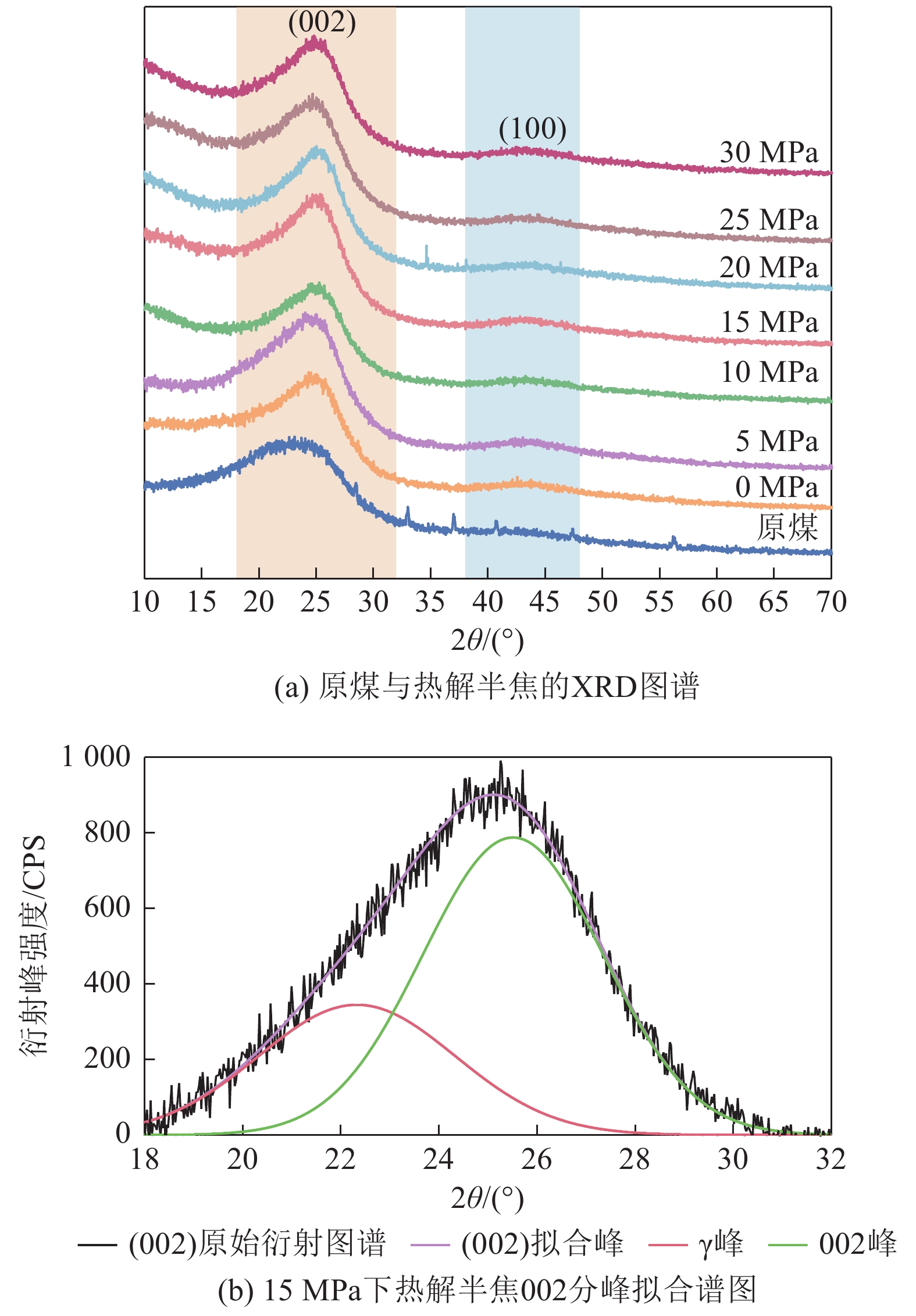

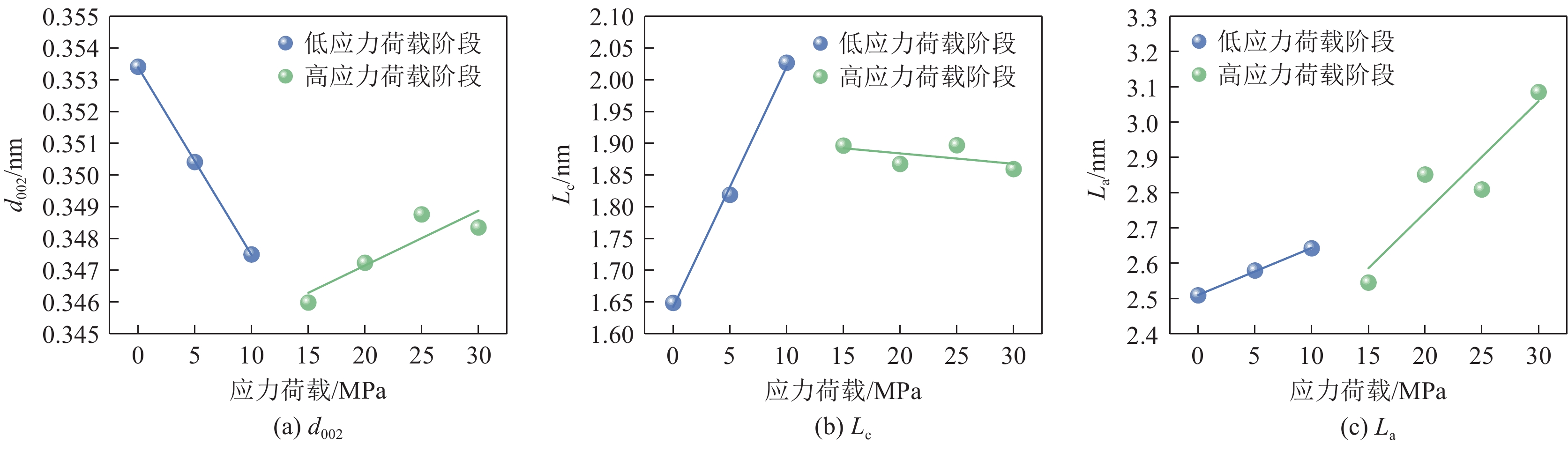

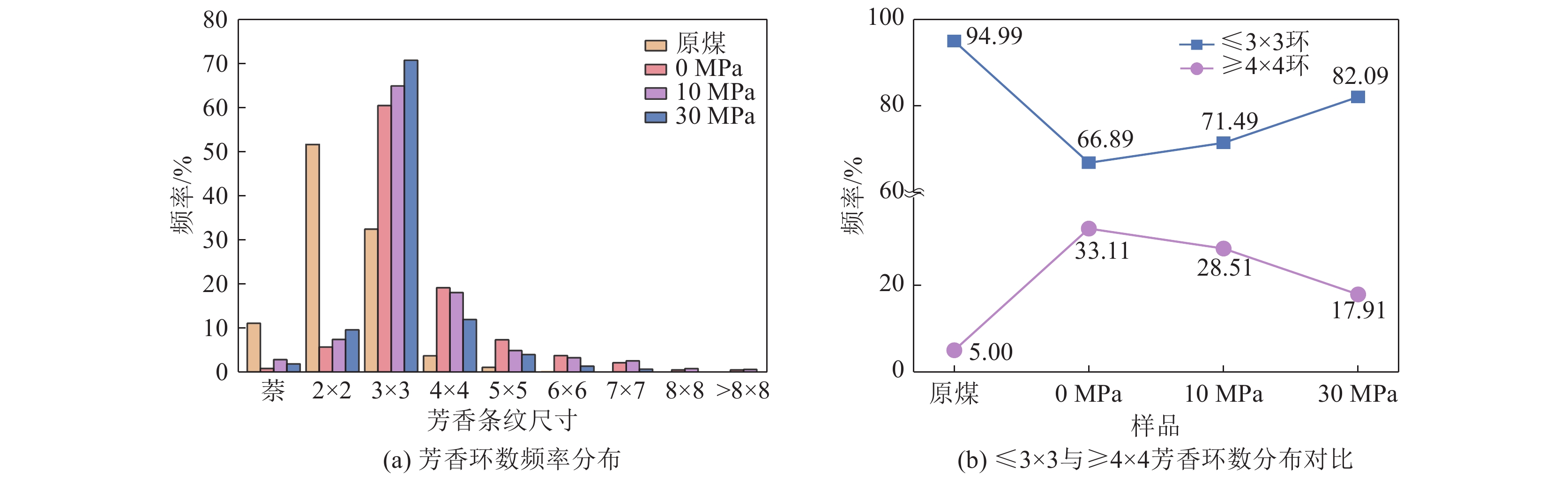

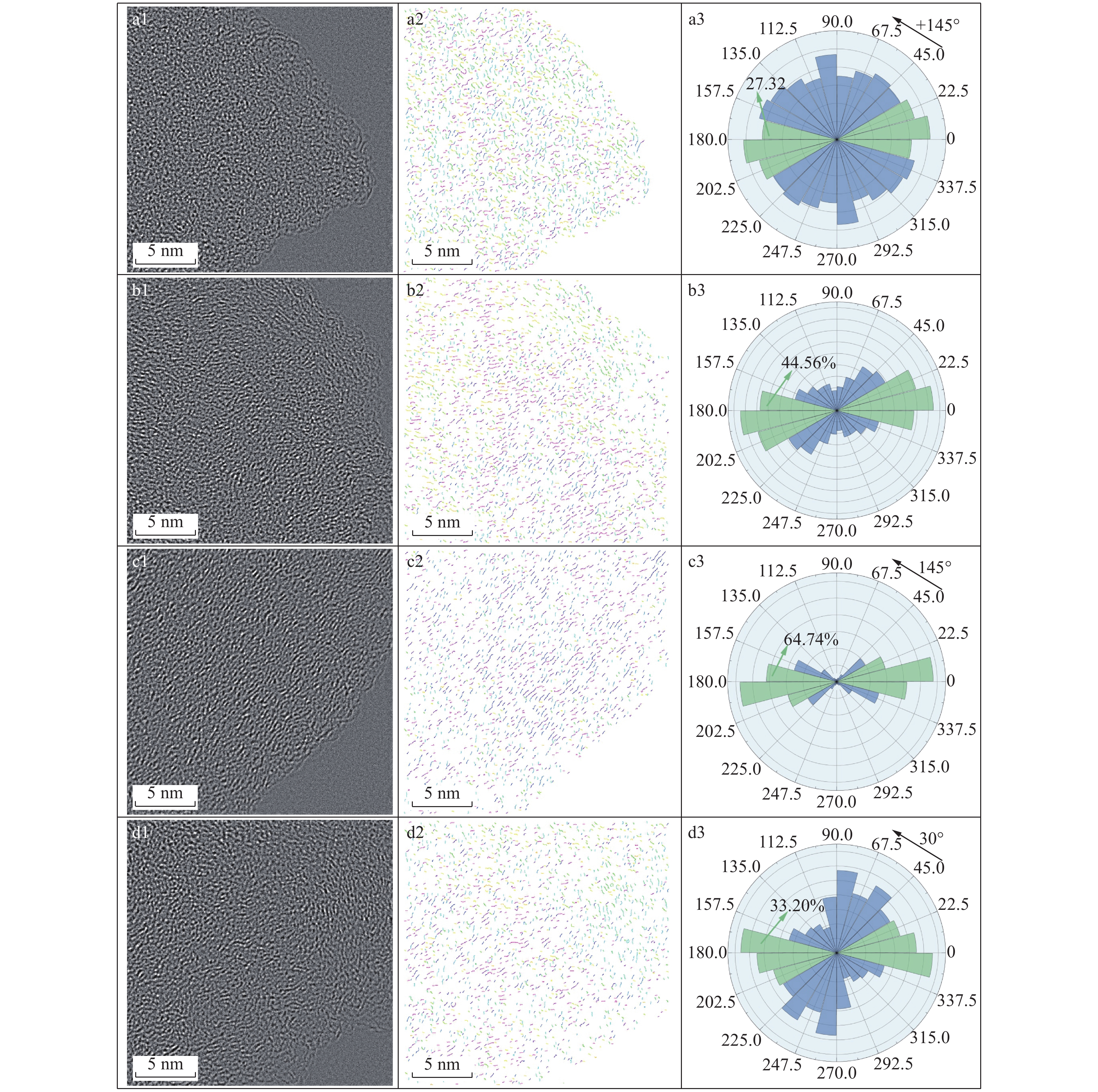

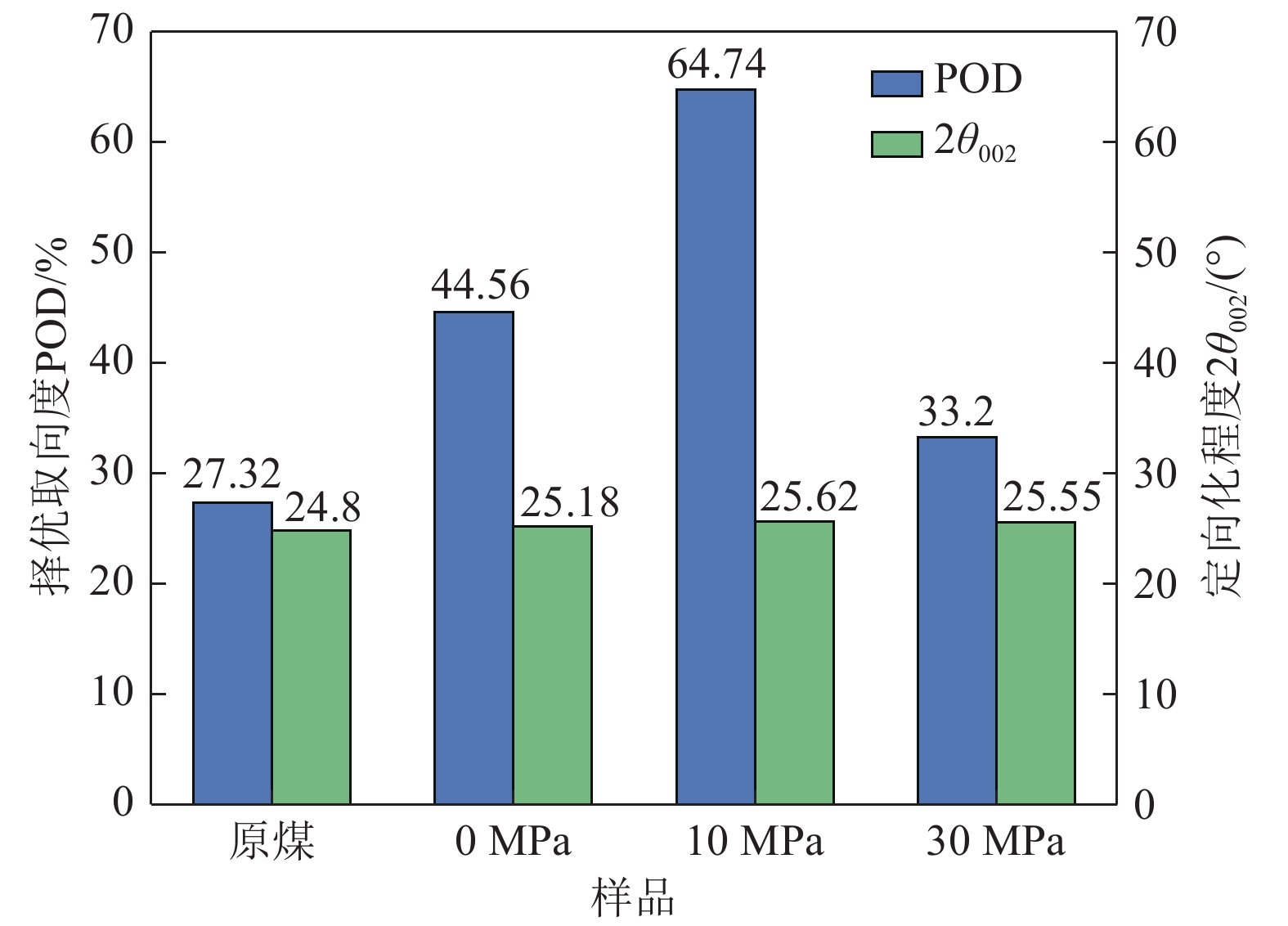

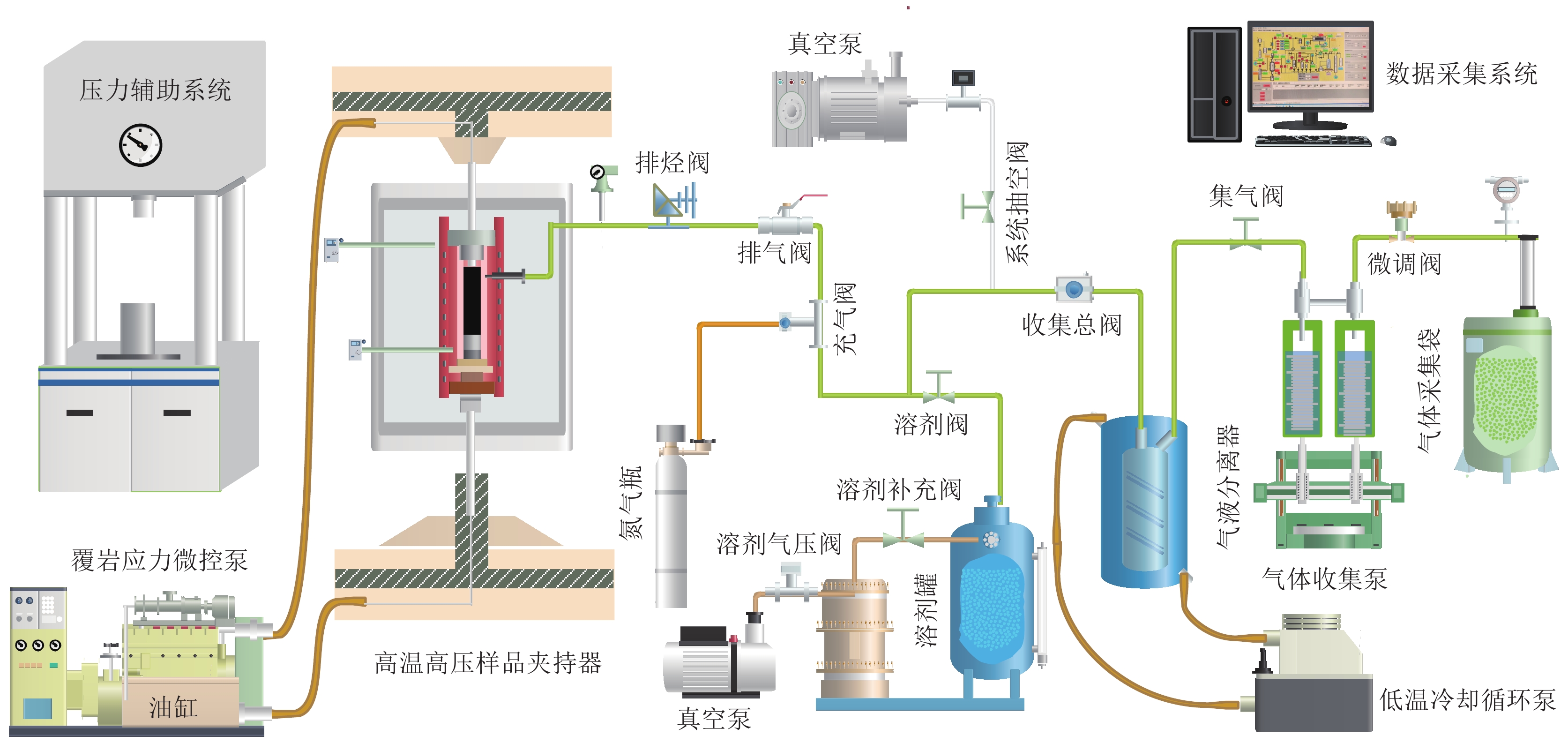

富油煤原位热解油气转化为提高国内油气自主保障和推动煤炭绿色低碳产业提供了新思路,原位地层条件约束下富油煤热解行为与常规地面热解不同,造成油气产出规律差异显著,但相关研究甚少。通过模拟不同覆岩应力下富油煤原位热解过程,利用低温氮气吸附实验、X-射线衍射和高分辨率透射电子显微镜等手段研究地层应力对煤体热解宏观膨胀变形、微观孔隙结构演化和半焦分子结构的影响,探讨不同应力荷载对富油煤热解的作用机制。结果表明:随着应力荷载的增强,富油煤原位热解特性呈现出2个明显的阶段性特征。低应力荷载阶段(0~10 MPa),由于煤样缺乏有效的径向围限压力,导致轴向应力的增强不断压裂煤体,从而增强了孔隙连通性和热解流体释放能力,一方面有利于在对流过程中形成大孔,即 > 50 μm热解大孔数量显著增多;另一方面降低了热解流体二次反应几率,进而提高焦油产率、促进煤分子结构有序化生长,表现为面网间距逐渐减小、堆砌度和延展度逐渐增大,镜质组随机反射率不断提高。然而,在高应力荷载阶段(> 10 MPa),煤体被不断压实、裂隙闭合,内部热解流体运移受到显著抑制,一方面在较弱对流下更易形成2~25 μm相对较小孔隙;另一方面强化了热解流体的二次反应程度,从而使焦油产率降低、产气量和半焦产率提高,X-射线衍射和高分辨率透射电镜数据显示持续高压滞流造成煤基质膨胀变形不利于热解半焦芳香结构秩理化生长。

Abstract:The oil and gas conversion of tar-rich coal in-situ pyrolysis provides a new idea to improve the domestic oil and gas independent guarantee and push the green and low-carbon industry of coal. The behavior of tar-rich coal pyrolysis under crustal stress is distinct from conventional ground pyrolysis, leading to significant differences in oil and gas output law, but there are few relevant studies. Tar-rich coal pyrolysis simulation experiments under different overburden stresses were conducted, and the influence of the crustal stress on pyrolysis deformation, pore structure evolution, and molecular structure disparities was analyzed using low-temperature N2 adsorption, X-ray diffraction, and high-resolution transmission electron microscopy. The effect mechanism of the different stress loadings on the pyrolysis of tar-rich coals was explored. The results showed the tar-rich coal in-situ pyrolysis properties exhibited two stages as the stress loading increased. During the low-stress loading stage (0~10 MPa), the lack of effective radial confining pressure on the coal samples resulted in the enhancement of axial stress constantly fracturing the coal, improving pore connectivity and pyrolysis fluid release ability. On the one hand, it was conducive to the formation of large pores during convection, and the number of > 50 μm pyrolysis macropores increased significantly; on the other hand, it was conducive to the reduction of the chance of the secondary reaction of pyrolysis fluid, which led to the improvement of tar yield and the growth of the coal molecular structure, which was reflected in the gradual decrease in interlayer spacing, the gradual increase in stacking height and lateral size, and the increase in random vitrinite reflectance from the optical properties. However, the compaction of coal and the closure of fissures at the high-stress loading stage ( > 10 MPa), inhibit internal pyrolysis volatile migration; on the one hand, it is easier to form a relatively small pore size of 2-25 μm under the weak convection; on the other hand, it strengthens the degree of secondary reaction of pyrolysis fluids, leading to a reduction in the tar yield and an increase in the gas and semi-coke yields. Furthermore, X-ray diffraction and high-resolution transmission electron microscopy data indicated that the swelling deformation of the coal matrix caused by the continuous high-pressure stagnant flow was not favorable to the orderly growth of pyrolysis semi-coke aromatic structure.

-

Keywords:

- tar-rich coal /

- in-situ pyrolysis /

- stress loading /

- product distribution /

- oil and gas conversion

-

表 1 原煤煤质特征数据

Table 1 The date of quality characteristics of raw coal

工业分析/% 元素分析/% 煤岩分析/% FCad Mad Ad Vdaf Std Cdaf Hdaf Odaf Ndaf V I L M 54.27 6.26 3.88 39.77 0.27 81.71 5.26 11.78 0.98 54.33 42.00 0.34 3.33 表 2 高分辨率透射电子显微镜中晶格条纹类型

Table 2 Classification of lattice fringes in a high resolution transmission electron microscope

芳香条纹尺寸 芳香条纹长度/nm 最小值 最大值 平均值 归类 萘 0.28 0.49 0.39 0.30~0.54 2×2 0.49 0.71 0.60 0.55~0.74 3×3 0.74 1.13 0.93 0.75~1.14 4×4 0.98 1.56 1.27 1.15~1.44 5×5 1.23 1.98 1.60 1.45~1.74 6×6 1.47 2.41 1.94 1.75~2.04 7×7 1.72 2.84 2.28 2.05~2.44 8×8 1.96 3.26 2.61 2.45~2.84 表 3 热解半焦样品的煤质特征

Table 3 Characteristics of semi-coke samples derived from pyrolysis

应力载荷/MPa 元素分析 H/C Roran/% Std Cdaf Hdaf Ndaf 0 0.14 86.39 2.04 0.89 0.283 3.91 5 0.12 87.16 2.04 1.07 0.281 3.93 10 0.14 88.01 2.04 0.98 0.278 3.98 15 0.08 87.56 2.05 0.91 0.281 3.95 20 0.12 86.74 2.05 0.99 0.284 3.89 25 0.08 89.25 2.13 1.01 0.286 3.84 30 0.14 88.81 2.19 1.11 0.296 3.86 -

[1] 王双明,师庆民,王生全,等. 富油煤的油气资源属性与绿色低碳开发[J]. 煤炭学报,2021,46(5):1365−1377. WANG Shuangming, SHI Qingmin, WANG Shengquan, et al. Resource property and exploitation concepts with green and low-carbon of tar-rich coal as coal-based oil and gas[J]. Journal of China Coal Society,2021,46(5):1365−1377.

[2] 段中会,杨甫,王振东,等. 陕北富油煤地下原位热解先导试验[J]. 煤田地质与勘探,2024,52(7):14−24. DUAN Zhonghui, YANG Fu, WANG Zhendong, et al. Pilot experiment for underground in situ pyrolysis of tar-rich coal in the northern Shaanxi Province[J]. Coal Geology & Exploration,2024,52(7):14−24.

[3] KOU B Y, SHI Q M, WANG S M, et al. Axial pressure impact on pyrolysis behavior of Xinjiang coal:An inspiration for in situ pyrolysis of tar-rich coal[J]. Fuel Processing Technology,2025,267:108175. doi: 10.1016/j.fuproc.2024.108175

[4] SHI Q M, CUI S D, WANG S M, et al. Experiment study on CO2 adsorption performance of thermal treated coal:Inspiration for CO2 storage after underground coal thermal treatment[J]. Energy,2022,254:124392. doi: 10.1016/j.energy.2022.124392

[5] 吴学海,李波波,王新,等. 基于塑性变形的煤体损伤本构关系及渗透率模型研究[J]. 煤田地质与勘探,2021,49(6):131−141. WU Xuehai, LI Bobo, WANG Xin, et al. Plastic deformation-based constitutive relation of coal damage and permeability model[J]. Coal Geology & Exploration,2021,49(6):131−141.

[6] GAN Q Q, XU J, PENG S J, et al. Effect of heating on the molecular carbon structure and the evolution of mechanical properties of briquette coal[J]. Energy,2021,237:121548. doi: 10.1016/j.energy.2021.121548

[7] 俞尊义,郭伟,杨盼曦,等. 陕北富油煤热解提油产物分布特性研究[J]. 煤田地质与勘探,2024,52(7):176−188. YU Zunyi, GUO Wei, YANG Panxi, et al. Distributions of products from the pyrolysis of tar-rich coals for tar extraction in northern Shaanxi Province, China[J]. Coal Geology & Exploration,2024,52(7):176−188.

[8] 刘源,贺新福,杨伏生,等. 热解温度及气氛变化对神府煤热解产物分布的影响[J]. 煤炭学报,2015,40(S2):497−504. LIU Yuan, HE Xinfu, YANG Fusheng, et al. Impacts of pyrolysis temperature and atmosphere on product distribution of Shenfu coal pyrolysis[J]. Journal of China Coal Society,2015,40(S2):497−504.

[9] 郝静远,齐宝金,魏进家. 不同压力下榆神地区富油煤原位热解产物特性[J]. 化工进展,2024,43(S1):268−281. HAO Jingyuan, QI Baojin, WEI Jinjia. Characteristics of in situ pyrolysis products of tar-rich coal in Yushen area under different pressures[J]. Chemical Industry and Engineering Progress,2024,43(S1):268−281.

[10] ZENG D, FLETCHER T H. Effects of pressure on coal pyrolysis and char morphology[J]. Energy & Fuels,2005,19(5):1828−1838.

[11] WU H W, BRYANT G, BENFELL K, et al. An experimental study on the effect of system pressure on char structure of an Australian bituminous coal[J]. Energy & Fuels,2000,14(2):282−290.

[12] LEE C W, SCARONI A W, JENKINS R G. Effect of pressure on the devolatilization and swelling behaviour of a softening coal during rapid heating[J]. Fuel,1991,70(8):957−965. doi: 10.1016/0016-2361(91)90051-B

[13] BIKANE K, YU J, LONG X Y, et al. Linking char reactivity to structural and morphological evolution during high pressure pyrolysis of Morupule coal[J]. Chemical Engineering Science:X,2020,8:100072.

[14] CAI H Y, GÜELL A J, CHATZAKIS I N, et al. Combustion reactivity and morphological change in coal chars:Effect of pyrolysis temperature, heating rate and pressure[J]. Fuel,1996,75(1):15−24. doi: 10.1016/0016-2361(94)00192-8

[15] NIU M F, WANG R N, MA W P, et al. Methane formation mechanism during pressurized pyrolysis of coal core in the context of deep underground coal gasification[J]. Fuel,2022,324:124668. doi: 10.1016/j.fuel.2022.124668

[16] ZHANG W D, ZHAO Y J, SUN S Z, et al. Effects of pressure on the characteristics of bituminous coal pyrolysis char formed in a pressurized drop tube furnace[J]. Energy & Fuels,2019,33(12):12219−12226.

[17] LIN D, LIU L, ZHAO Y, et al. Influence of pyrolysis pressure on structure and combustion reactivity of Zhundong demineralized coal char[J]. Journal of the Energy Institute,2020,93(5):1798−1808. doi: 10.1016/j.joei.2020.03.011

[18] 冯子军,万志军,赵阳升,等. 热力耦合作用下无烟煤煤体变形特征的试验研究[J]. 岩石力学与工程学报,2010,29(8):1624−1630. FENG Zijun, WAN Zhijun, ZHAO Yangsheng, et al. Experimental investigation into deformation characteristics of anthracite under thermo-mechanical coupling conditions[J]. Chinese Journal of Rock Mechanics and Engineering,2010,29(8):1624−1630.

[19] 许时昂,张平松,程刚,等. 富油煤原位热解地质环境影响与地质保障技术[J]. 煤田地质与勘探,2024,52(7):73−84. XU Shiang, ZHANG Pingsong, CHENG Gang, et al. In-situ pyrolysis of tar-rich coal:Effects on geological environments and geological guarantee technology[J]. Coal Geology & Exploration,2024,52(7):73−84.

[20] 师庆民,米奕臣,王双明,等. 富油煤热解流体滞留特征及其机制[J]. 煤炭学报,2022,47(3):1329−1337. SHI Qingmin, MI Yichen, WANG Shuangming, et al. Trap characteristic and mechanism of volatiles during pyrolysis of tar-rich coal[J]. Journal of China Coal Society,2022,47(3):1329−1337.

[21] SHI Q M, SHI Y Y, WANG S M, et al. Experimental study on the tar and gas distribution during tar-rich coal pyrolysis with stress loading[J]. Fuel,2024,376:132727. doi: 10.1016/j.fuel.2024.132727

[22] CHENG N N, PAN J N, SHI M Y, et al. The impacts of stress on the macromolecular structure of anthracites:Implications for the mechanochemical effects[J]. International Journal of Coal Geology,2022,264:104151. doi: 10.1016/j.coal.2022.104151

[23] 曹代勇,李小明,魏迎春,等. 构造煤与原生结构煤的热解成烃特征研究[J]. 煤田地质与勘探,2005,33(4):39−41. CAO Daiyong, LI Xiaoming, WEI Yingchun, et al. Study on pyrogenation hydrocarbon generation character of deformed coal and undeformed coal[J]. Coal Geology & Exploration, 2005, 33(4):39−41.

[24] SHI Q M, LI C H, WANG S M, et al. Variation of molecular structures affecting tar yield:A comprehensive analysis on coal ranks and depositional environments[J]. Fuel,2023,335:127050. doi: 10.1016/j.fuel.2022.127050

[25] 康红普,伊丙鼎,高富强,等. 中国煤矿井下地应力数据库及地应力分布规律[J]. 煤炭学报,2019,44(1):23−33. KANG Hongpu, YI Bingding, GAO Fuqiang, et al. Database and characteristics of underground in situ stress distribution in Chinese coal mines[J]. Journal of China Coal Society,2019,44(1):23−33.

[26] THOMMES M, KANEKO K, NEIMARK A V, et al. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report)[J]. Pure and Applied Chemistry,2015,87(9-10):1051−1069. doi: 10.1515/pac-2014-1117

[27] 李霞,曾凡桂,王威,等. 低中煤级煤结构演化的XRD表征[J]. 燃料化学学报,2016,44(7):777−783. LI Xia, ZENG Fangui, WANG Wei, et al. XRD characterization of structural evolution in low-middle rank coals[J]. Journal of Fuel Chemistry and Technology,2016,44(7):777−783.

[28] 姜波,秦勇,金法礼. 高温高压实验变形煤XRD结构演化[J]. 煤炭学报,1998,23(2):188−193. JIANG Bo, QIN Yong, JIN Fali. Xrd analysis of the structural evolution of deformed coal samples tested under high temperature and high confined pressure[J]. Journal of China Coal Society,1998,23(2):188−193.

[29] 李美芬,曾凡桂,齐福辉,等. 不同煤级煤的Raman谱特征及与XRD结构参数的关系[J]. 光谱学与光谱分析,2009,29(9):2446−2449. LI Meifen, ZENG Fangui, QI Fuhui, et al. Raman spectroscopic characteristics of different rank coals and the relation with XRD structural parameters[J]. Spectroscopy and Spectral Analysis,2009,29(9):2446−2449.

[30] 任秀彬,辛文辉,张亚婷,等. 基于HRTEM的低阶烟煤微晶结构研究[J]. 煤炭学报,2015,40(S1):242−246. REN Xiubin, XIN Wenhui, ZHANG Yating, et al. Structural alignment of low rank coal using HRTEM technique[J]. Journal of China Coal Society,2015,40(S1):242−246.

[31] LI J Q, QIN Y, CHEN Y L, et al. HRTEM observation of morphological and structural evolution of aromatic fringes during the transition from coal to graphite[J]. Carbon,2022,187:133−144. doi: 10.1016/j.carbon.2021.11.006

[32] 宋昱,姜波,王猛,等. 煤缩合芳环应力响应:对无烟煤石墨化的启示[J]. 煤炭学报,2022,47(12):4336−4351. SONG Yu, JIANG Bo, WANG Meng, et al. Stress response of coalcondensed aromatic ring:Inspiration for graphitization of anthracite[J]. Journal of China Coal Society,2022,47(12):4336−4351.

[33] 王双明,师庆民,孙强,等. 富油煤原位热解技术战略价值与科学探索[J]. 煤田地质与勘探,2024,52(7):1−13. WANG Shuangming, SHI Qingmin, SUN Qiang, et al. Strategic value and scientific exploration of in situ pyrolysis of tar-rich coals[J]. Coal Geology & Exploration,2024,52(7):1−13.

[34] SUN S Y, XU D H, WEI Y, et al. Influence laws of operating parameters on coal pyrolysis characteristics[J]. Journal of Analytical and Applied Pyrolysis,2022,167:105684. doi: 10.1016/j.jaap.2022.105684

[35] 尹振勇,许浩,汤达祯,等. 不同煤阶煤热解过程中孔隙结构变化规律研究[J]. 煤炭科学技术,2019,47(9):74−79. YIN Zhenyong, XU Hao, TANG Dazhen, et al. Study on pore structure change during different coal grade pyrolysis[J]. Coal Science and Technology,2019,47(9):74−79.

[36] 畅志兵,王楚楚,旷文昊,等. 黏结性对富油煤热解孔隙结构演变及渗流的影响研究[J]. 煤田地质与勘探,2024,52(7):54−63. CHANG Zhibing, WANG Chuchu, KUANG Wenhao, et al. Impacts of the caking property of tar-rich coals on their pore structure evolution and seepage during pyrolysis[J]. Coal Geology & Exploration,2024,52(7):54−63.

[37] LI P P, ZHANG X D, ZHANG S. Structures and fractal characteristics of pores in low volatile bituminous deformed coals by low-temperature N2 adsorption after different solvents treatments[J]. Fuel,2018,224:661−675. doi: 10.1016/j.fuel.2018.03.067

[38] 耿济世,王双明,孙强,等. 富油煤热解特性及其孔裂隙结构演化规律[J]. 煤田地质与勘探,2024,52(7):46−53. GENG Jishi, WANG Shuangming, SUN Qiang, et al. Pyrolysis characteristics and pore-fracture evolutionary patterns of tar-rich coals[J]. Coal Geology & Exploration,2024,52(7):46−53.

[39] YAN J C, LEI Z P, LI Z K, et al. Molecular structure characterization of low-medium rank coals via XRD, solid state 13C NMR and FTIR spectroscopy[J]. Fuel,2020,268:117038. doi: 10.1016/j.fuel.2020.117038

[40] 相建华,曾凡桂,梁虎珍,等. 不同变质程度煤的碳结构特征及其演化机制[J]. 煤炭学报,2016,41(6):1498−1506. XIANG Jianhua, ZENG Fangui, LIANG Huzhen, et al. Carbon structure characteristics and evolution mechanism of different rank coals[J]. Journal of China Coal Society,2016,41(6):1498−1506.

[41] LU L, SAHAJWALLA V, KONG C, et al. Quantitative X-ray diffraction analysis and its application to various coals[J]. Carbon,2001,39(12):1821−1833. doi: 10.1016/S0008-6223(00)00318-3

[42] NEWALKAR G, IISA K, D’AMICO A D, et al. Effect of temperature, pressure, and residence time on pyrolysis of pine in an entrained flow reactor[J]. Energy & Fuels,2014,28(8):5144−5157.

[43] TAHMASEBI A, MALIUTINA K, YU J L. Impact of pressure on the carbon structure of char during pyrolysis of bituminous coal in pressurized entrained-flow reactor[J]. Korean Journal of Chemical Engineering,2019,36(3):393−403. doi: 10.1007/s11814-018-0187-5

[44] Smith K L, Smoot L D, Fletcher T H, et al. The structure and reaction processes of coal[J]. Springer Science & Business Media 1994.

[45] LI M F, ZENG F G, CHANG H Z, et al. Aggregate structure evolution of low-rank coals during pyrolysis by in situ X-ray diffraction[J]. International Journal of Coal Geology,2013,116:262−269.

[46] 杨赫,谢周伟,尚妍,等. 淖毛湖煤热解产物中不同大小芳核的数量分布及变化规律[J]. 燃料化学学报,2021,49(11):1667−1675. YANG He, XIE Zhouwei, SHANG Yan, et al. The distribution and variation of aromatic nuclei in the pyrolysis products of Naomaohu coal[J]. Journal of Fuel Chemistry and Technology,2021,49(11):1667−1675.

[47] LI J Q, QIN Y, SHEN J, et al. Evolution of carbon nanostructures during coal graphitization:Insights from X-ray diffraction and high-resolution transmission electron microscopy[J]. Energy,2024,290:130316. doi: 10.1016/j.energy.2024.130316

[48] SONG Y, JIANG B, LI M, et al. Macromolecular transformations for tectonically-deformed high volatile bituminous via HRTEM and XRD analyses[J]. Fuel,2020,263:116756. doi: 10.1016/j.fuel.2019.116756

[49] 刘振宇. 煤化学的前沿与挑战:结构与反应[J]. 中国科学:化学,2014,44(9):1431−1439. doi: 10.1360/N032014-00159 LIU Zhenyu. Advancement in coal chemistry:Structure and reactivity[J]. Scientia Sinica Chimica,2014,44(9):1431−1439. doi: 10.1360/N032014-00159

[50] 郭伟,杨盼曦,俞尊义,等. 陕北富油煤分子模型构建及其热解提油分子动力学特性[J]. 煤田地质与勘探,2024,52(7):132−143. GUO Wei, YANG Panxi, YU Zunyi, et al. Molecular modeling of tar-rich coals from northern Shaanxi and their molecular dynamic characteristics in the process of pyrolysis for tar extraction[J]. Coal Geology & Exploration,2024,52(7):132−143.

下载:

下载: