Numerical simulation of CO2-ECBM based on 3D heterogeneous geological model

-

摘要:

CO2驱煤层气地质封存(CO2-ECBM)强化煤层气开发、实现煤层气井增产的同时,将CO2封存到深部煤层中,该技术极具发展前景。依托示范工程,基于地质建模开展数值模拟研究,仍是技术研发的重要路径。基于对角点地质模型和COMSOL Multiphysics地质建模能力的分析,利用拆分−重构法在COMSOL Multiphysics内建立了能有效描述沁水盆地柿庄南区块3号煤储层的三维空间展布和含气量、吸附时间、孔隙度、渗透率、弹性模量、泊松比非均质分布的地质模型。在此基础上,结合吸附−渗流−温度−应力−化学(AHTMC)多场耦合数学模型开展了控压注气方式的CO2-ECBM数值模拟工作,分析了CO2注入压力对CH4增产、CO2封存及煤储层地球化学环境的影响,提出了同时关井、序贯关井2种关井方式和省时提效、CH4增产、CO2封存以及3者综合兼顾4种CO2-ECBM工程目标,优化了2种关井方式、分别实现4种工程目标场景下的CO2注入压力。研究结果表明:① 在15 a工期、5.5~9.5 MPa注气压力情况下,随着注入井CO2注气压力的增加,生产井CH4增产率、煤储层CO2封存量均增加,最大可分别达14.39%和8.31×107 m3,含酸性裂隙水的煤储层区域扩大,受CO2从生产井大量产出的影响,储层CO2封存率降低,但保持在95%以上;② 煤储层非均质性对煤层气井生产影响很大,煤层气井周围煤储层CH4含气量越高、孔隙度和渗透率越大,CH4增产效果越显著,周围煤储层吸附CO2能力越强,CO2产出速度越小;③ 同时关井和序贯关井方式下,CO2注气压力对生产井组产出气CO2体积分数和CH4产气速度变化有显著影响,CO2-ECBM工程结束时煤储层CH4采收率随注气压力增加而降低,3.50、6.50、9.50 MPa的注气压力下分别为33.28%、18.90%、12.81%和41.63%、29.03%、23.01%;④ 以省时提效、CH4增产、CO2封存及3者综合兼顾为工程目标的CO2最优注入压力在同时关井时分别为8.05、3.50、6.35和6.25 MPa,在序贯关井时分别9.50、9.50、3.50和9.50 MPa;⑤ 相较于同时关井,序贯关井在采用最优CO2注气压力时能够通过延长工程时间获得较好的CH4增产和CO2封存效果。

-

关键词:

- CO2驱煤层气地质封存 /

- 三维非均质地质模型 /

- 煤层气增产 /

- CO2封存 /

- 注入工艺优化

Abstract:CO2 geological sequestration-enhanced coalbed methane (CO2-ECBM) strengthens the development of coalbed methane (CBM) and realizes the stimulation of coalbed methane wells. At the same time, CO2 is stored in deep coal seams. This technology has some great development prospects. Relying on the demonstration project, numerical simulation based on geological modeling is still an important path for its technological development. Based on the analysis of the characteristics for the corner grid geological model and the geological modeling ability of COMSOL Multiphysics, a geological model that can clearly display the three-dimensional spatial morphology and heterogeneity distribution of gas content, adsorption time, porosity, permeability, elastic modulus and Poisson’s ratio of the No. 3 coal in the Shizhuang South Block of Qinshui Basin was established in COMSOL Multiphysics using the split-reconstruction method. On this basis, the numerical simulation of CO2-ECBM for controlling gas injection pressure was carried out in combination with the adsorption-hydraulic-thermal-mechanical-chemical (AHTMC) multi-field coupling mathematical model, and the impact of CO2 injection pressure on CH4 stimulation, CO2 storage and the geochemical environment of coal reservoir were analyzed. Moreover, two kinds of shut-in modes, namely, simultaneous shut-in and sequential shut-in, and four CO2-ECBM engineering objectives, namely, time saving, CH4 stimulation, CO2 storage and comprehensive consideration of the three, were proposed. In addition, the CO2 injection pressures were optimized according to the two shut-in modes with the four objectives. The results show that: ① Under the limit of 15-year and the injection pressure of 5.50−9.50 MPa for the CO2-ECBM project, with the increase of CO2 injection pressure, the CH4 production rate of CBM wells and the CO2 storage capacity of coal reservoir increase, with the maximum of 14.39% and 8.31×107 m3 respectively, the area of coal reservoir containing acid fissure water expands. The CO2 storage rate decreases due to the large output of CO2 from CBM wells with the increase of gas injection pressure, but remains above 95%. ② The heterogeneity of coal reservoirs has a great impact on the production of CBM wells. The higher the CH4 content and the greater the porosity and permeability of the coal reservoirs around the CBM wells, the more significant the CH4 stimulation effect. The stronger the CO2 adsorption capacity of the coal reservoirs surrounding CBM wells, the lower their CO2 production rate. ③ Under the simultaneous and sequential shut-in, CO2 injection pressure has a significant impact on the CO2 concentration and CH4 production rate of gas produced by well group, and the CH4 recovery of coal reservoir decreases with the increase of injection pressure at the end of CO2-ECBM project with 33.28% and 41.63% for 3.50 MPa, 18.90% and 28.03% for 6.50 MPa and 12.81% and 23.01% for 9.50 MPa, respectively. ④ The optimal injection pressure of CO2 for the engineering objectives of time saving, CH4 stimulation, CO2 storage and comprehensive consideration of above three are 8.05, 3.50, 6.35 and 6.25 MPa for the simultaneous shut-in, respectively, and 9.50, 9.50, 3.50 and 9.50 MPa for the sequential shut-in, respectively. ⑤ Compared with simultaneous shut-in, the sequential shut-in can achieve better CH4 stimulation and CO2 storage effects by extending the engineering time when using the optimal CO2 injection pressure.

-

CO2驱煤层气地质封存(CO2-ECBM)通过向富含CH4的煤储层注入CO2,能够有效地提高煤层气(CBM)井CH4产气速度,并将CO2封存于煤层内,是提高非常规天然气开采、实现“碳达峰”与“碳中和”目标的一条重要路径。当前,世界范围内开展了多次CO2-ECBM场地试验,有利地证明了CO2-ECBM的可行性与有效性[1-2]。自20世纪90年代中期起,美国先后在圣胡安盆地、伊利诺伊盆地、阿巴拉契亚盆地、威利斯顿盆地、黑勇士盆地实施了多次CO2-ECBM场地试验,加拿大在阿尔伯塔省先后开展了名为FBV 4A和CSEMP的CO2-ECBM场地试验[2-3]。此外,德国、波兰和日本也开展了CO2-ECBM先导性试验[3-6]。我国从2004年开始在沁水盆地和鄂尔多斯盆地多次实施了不同规模的CO2-ECBM场地示范试验。其中,最后一次位于沁水盆地柿庄南区块,目标层位为山西组3号煤储层,自2020年6月至2021年6月共向储层内注入CO2约2 000 t[1]。

为支持CO2-ECBM工程实施,国内外开展了许多相关数值模拟工作。凡永鹏[7]和刘世奇[8]等基于均质煤储层地质模型和渗流−温度−应力(HTM)多场耦合数学模型分析了CO2注入煤层后储层孔隙度和渗透率的变化情况,发现受煤基质吸附CO2膨胀变形和解吸CH4收缩变形的影响[9-10],储层孔隙度和渗透率在CO2吸附区显著下降,在CO2未波及区或逐渐升高或先小幅降低再升高。ZHANG等[11]利用数值模拟发现沁水盆地柿庄北区块SX006井组CH4采收率在CO2注入2 a后会增加,整个井组CO2封存潜力约为12 616 t。FAN等[12]基于数值模拟研究发现,与初次开采(未向煤层注CO2)相比,CO2-ECBM过程中煤层气井的CH4产气峰值较高但在时间上存在延迟。LIU等[13]通过数值模拟分析认为以4~8 MPa向柿庄南3号煤层注入CO2,50 d后单井CO2存储量可达0.73×105~2.54×105 m3。此外,在CO2注入优化方面,SAMS等[14]指出注气优化需要兼顾到CO2封存量和CH4产气量;PERERA等[15]发现CO2注气压力在CO2-ECBM工艺优化中起主导作用。

上述模拟研究工作有助于更好地理解CO2-ECBM过程,为CO2-ECBM工程实施提供一定帮助,但对CO2-ECBM实际工程的指导仍存在一些问题,主要表现在:① 地质模型过于简单,缺乏对煤储层构造与属性非均质分布的考虑;② 数学建模不够完善,忽视了CO2注入对煤储层化学场变化的影响;③ 注气优化不够详实,缺少对CO2-ECBM实际工程时间和井组关井方式的约束。笔者在前人研究基础上,构建了基于COMSOL Multiphysics的柿庄南3号煤储层三维非均质地质模型,通过CO2-ECBM数值模拟分析了CO2注入压力对煤储层CH4增产、CO2封存和地球化学环境变化的影响,结合CO2-ECBM工程时间和井组关井方式,优化了不同工程目标的CO2注气压力。

1. 基于COMSOL Multiphysics的三维非均质地质模型

1.1 地质建模平台及模型

1.1.1 Petrel地质建模

作为一款专业地质建模软件,Petrel拥有多种先进的地质建模算法,如序贯指示模拟、序贯高斯模拟、和多点地质统计随机模拟等[16-17]。其建立的地质模型多为三维非均质角点地质模型,这种模型通过网格的节点坐标 (x, y, z) 确定模型的空间位置和构造特征,孔隙度和渗透率等属性参数赋存于每个网格块内。由于网格可以定义成任何立体几何形状,角点地质模型能够较准确地展示地层的三维展布形态和断层、尖灭等构造特征。

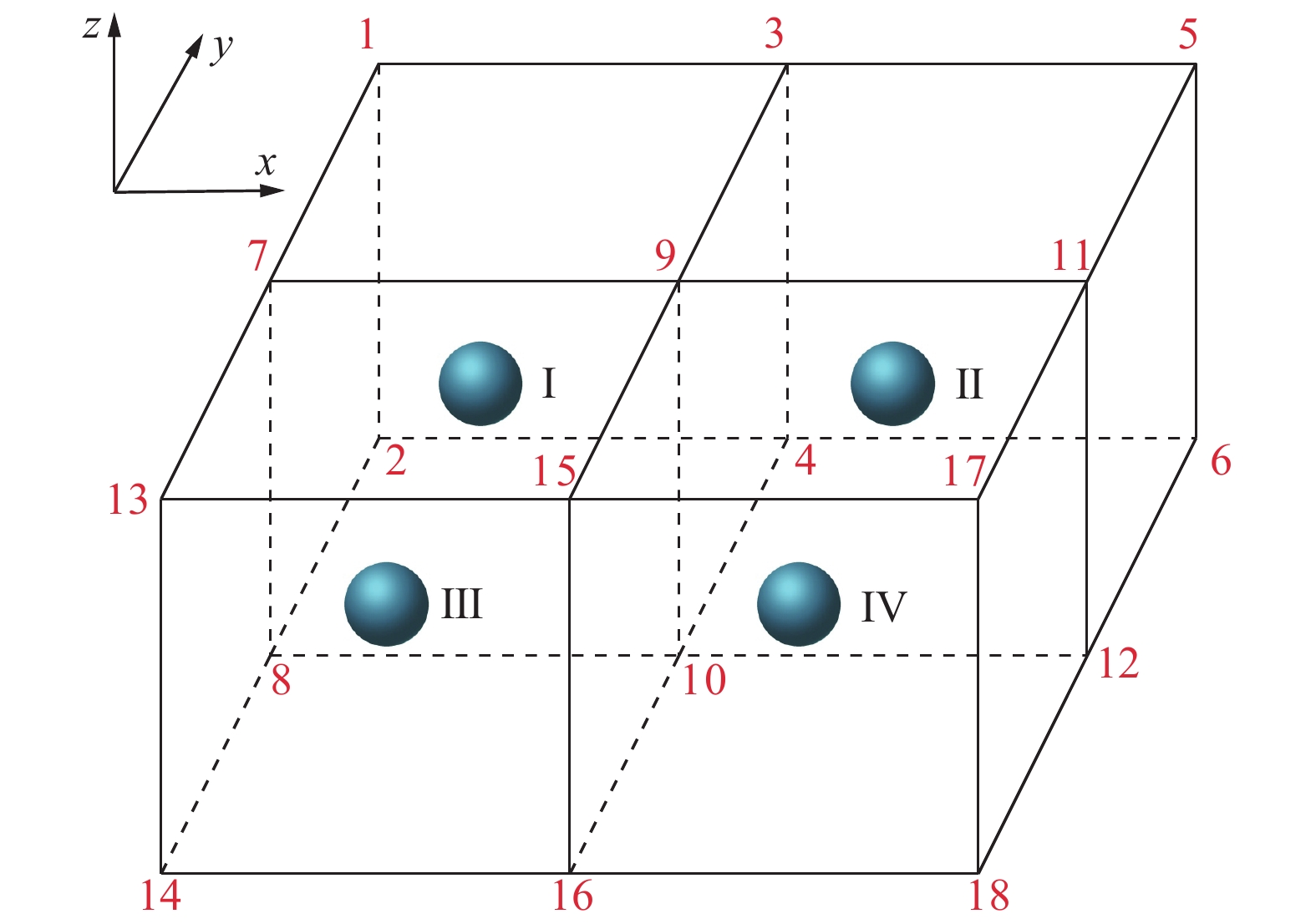

基于Petrel平台建立的角点地质模型包含构造模型和属性模型。构造模型数据由每个网格节点的 (x, y, z) 空间坐标组成,网格节点空间排布顺序一般呈垂向纵切、先上后下、先左后右的排列特征。属性模型数据则根据完整网格的顺序依次排列。以图1中2×2×1的模型为例,构造模型的网格节点顺序依次为1(x1, y1, z1) → 2(x2, y2, z2) → 3(x3, y3, z3) → 4(x4, y4, z4) → 5(x5, y5, z5) → 6(x6, y6, z6) → 7(x7, y7, z7) → 8(x8, y8, z8) → 9(x9, y9, z9) → 10(x10, y10, z10) → 11(x11, y11, z11) → 12(x12, y12, z12) → 13(x13, y13, z13) → 14(x14, y14, z14) → 15(x15, y15, z15) → 16(x16, y16, z16) → 17(x17, y17, z17) → 18(x18, y18, z18),属性模型参数的排列顺序依次为Ⅰ → Ⅱ → Ⅲ → Ⅳ。

1.1.2 COMSOL Multiphysics地质建模

与专业地质建模软件Petrel不同,COMSOL Multiphysics的功能以数值模拟计算为主,地质建模能力则相对较弱。在三维地质建模方面,该软件缺乏相应的专业建模算法,不能独立完成非均质地质建模工作。尽管其地质建模能力相对较弱,但其内置的一些基础建模方法仍具有较大的意义。在构造建模方面上,COMSOL Multiphysics软件可以直接定义圆柱体、圆台、长方体、球体等多种立方体(图2)。在模型修饰方面,该软件具有回转、拉伸、扫掠、放样、布尔操作与分割、倒角、圆角和删除实体等多种处理方法。此外,它还能将导入的外部数据(如文本数据)通过线性内插、最邻近插值、参数化曲面等方法构建各种数据的三维空间分布特征。

1.2 拆分−重构建模方法

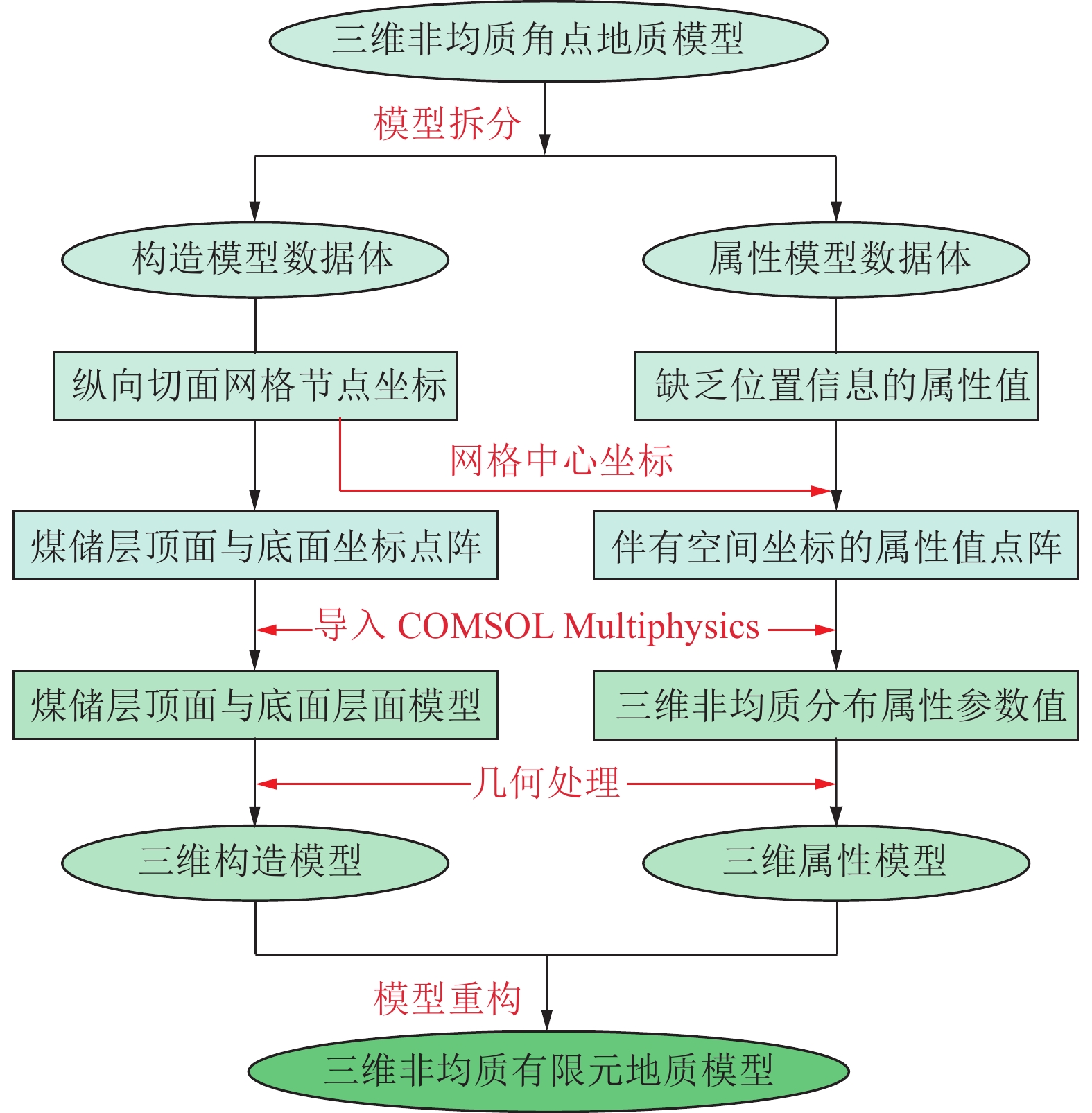

基于对Petrel平台所构建的角点地质模型特征和COMSOL Multiphysics建模能力的分析,笔者提出拆分−重构法将基于Petrel平台建立的沁水盆地柿庄南区块CO2-ECBM工程研究区煤储层三维非均质地质模型在COMSOL Multiphysics内进行重构。拆分−重构法的核心思想是将角点地质模型的构造模型和属性模型进行分拆,利用编程处理成COMSOL Multiphysics软件识别的数据体(如文本文件)。然后将数据体导入COMSOL Multiphysics软件,结合软件内置的基础建模方法,重构三维非均质地质模型,具体流程如图3所示。

1.2.1 模型拆分与数据处理

首先,将柿庄南区块煤层气井的井头、井斜、地层分层、测井曲线解释成果等数据导入Petrel软件,利用序贯高斯模拟方法建立煤储层三维非均质角点地质模型;通过关键点坐标构建Polygen边界将CO2-ECBM工程研究区分割出来。然后,从Petrel内将分割出来的三维非均质地质模型以.GRDECL的格式导出,并将其格式后缀修改为文本.txt形式,利用编程软件分别将描述构造模型的网格节点坐标和描述属性模型的参数值分别提取并存储。最后,通过编程方法,一方面将网格节点坐标转换成描述储层顶面和底面的坐标点阵,为建立层面模型做准备;另一方面根据网格节点坐标计算每个网格块的中心坐标,并与属性参数值结合构建伴有空间坐标的属性参数点阵。

1.2.2 数据导入与模型重构

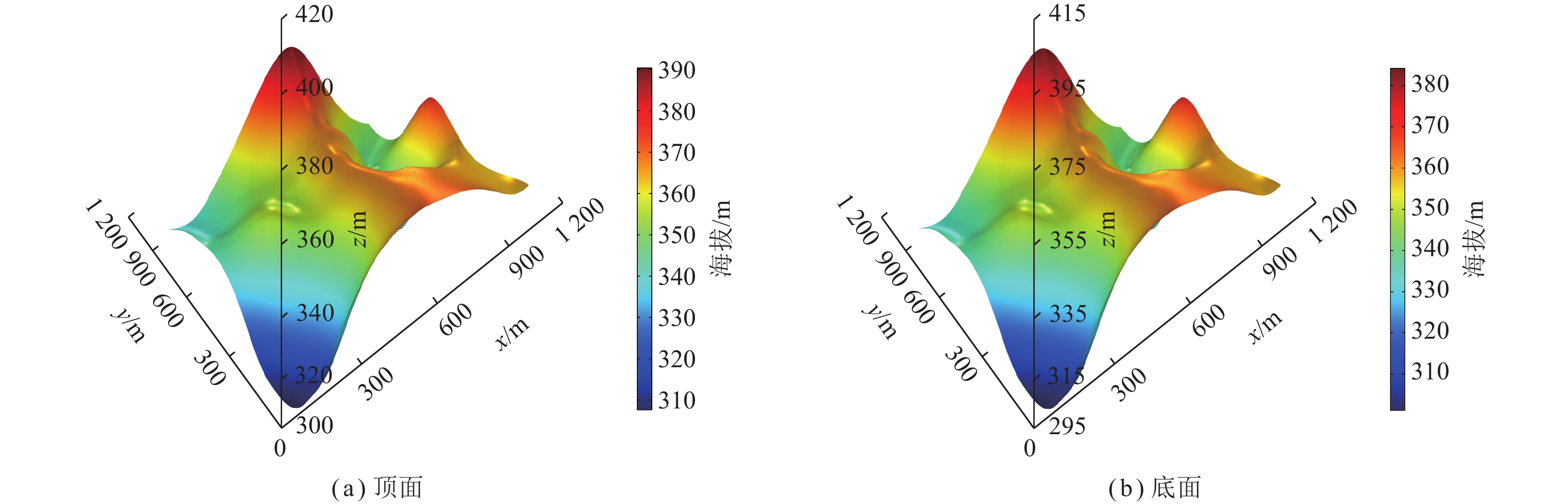

首先,将包含有煤层顶、底面坐标点阵的文本文件通过插值函数功能导入COMSOL Multiphysics,使用参数化曲面功能构建煤储层的顶面模型和底面模型(图4),它们共同构成煤储层的构造模型。然后,再将伴有空间位置信息的属性参数点阵导入软件,通过线性内插方法构建在三维空间上呈非均质分布的属性模型。最后,结合煤储层顶、底层面所占空间范围及各煤层气井的空间位置与井径尺寸,利用COMSOL Multiphysics软件内置的立方体建模、布尔操作、分割和删除实体等一系列几何处理功能,建立煤储层和煤层气井[18]。经过上述处理后,一个完整的煤储三维非均质地质模型即可构建完成。

1.3 模型重构结果、检验与网格划分

1.3.1 地质模型重构结果

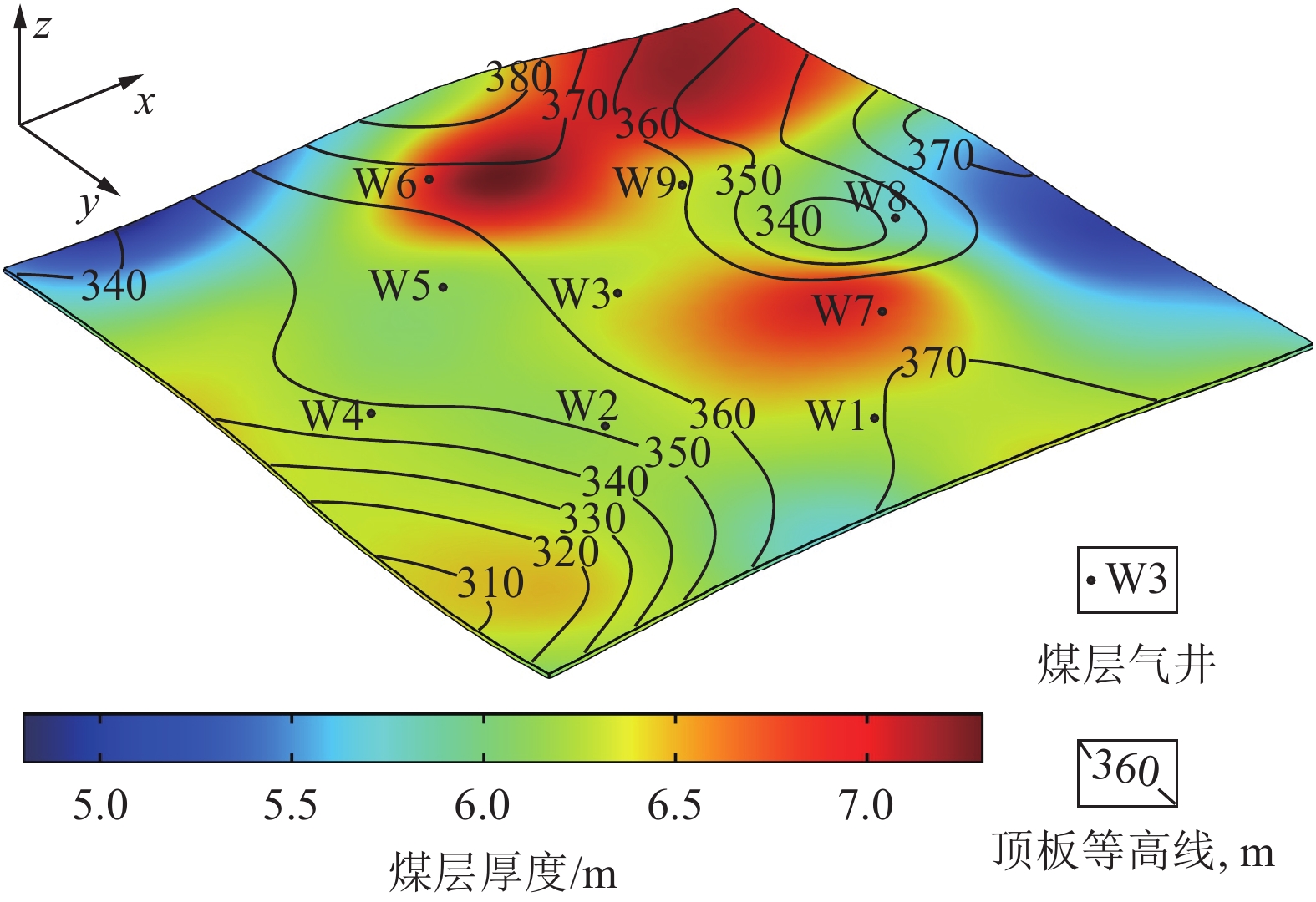

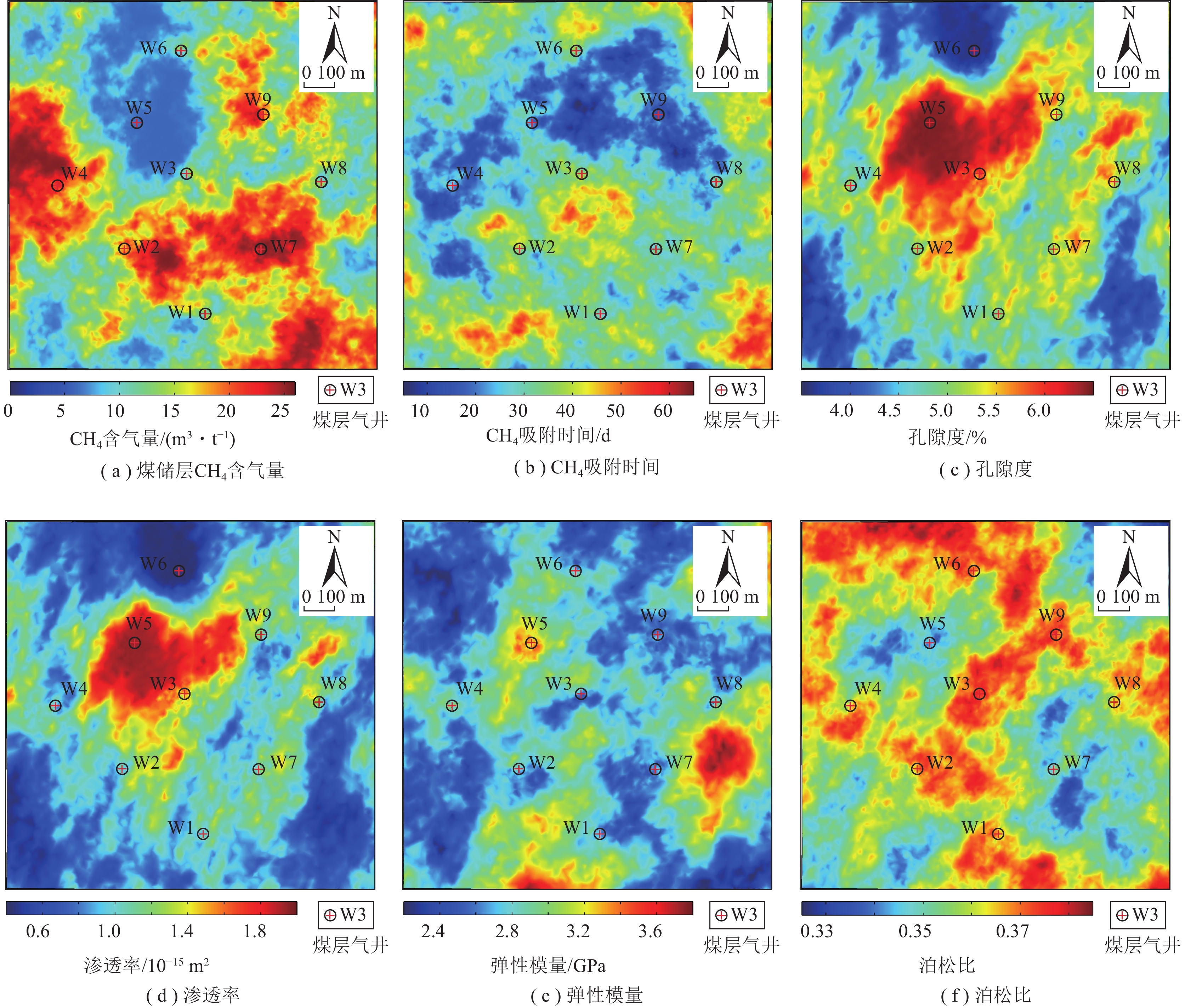

利用拆分−重构法在COMSOL Multiphysics内重构的CO2-ECBM研究区煤储层非均质地质模型如图5和图6所示[1]。模型内共有9口煤层气井,其中W3井是CO2-ECBM工程的CO2注入井,其余井为生产井。煤储层厚度主要为5.00~7.00 m,平均6.26 m,厚煤层主要分布于东北部地区,局部厚度超过7.00 m;薄煤层主要位于模型东南部和西北部边缘地区,最薄处低于5.00 m(图5)。煤储层CH4含气量主要为5.00~25.00 m3/t,平均14.12 m3/t;W2、W4、W7和W9井所在位置附近区域煤储层CH4含气量较高,局部地区超过18 m3/t(图6(a))。CH4吸附时间主要为20~50 d,平均31.35 d;高吸附时间区域主要集中于模型南部及边界,低吸附时间主要分布于模型的中偏北部(图6(b))。

孔隙度主要为4.00%~6.00%,平均5.03%。相较于其他位置,模型中部区域煤储层的孔隙度较大,W5井所处位置及其周围区域的孔隙度超过5.55%。模型北部的W6井所处位置及周边区域煤储层孔隙度较低,甚至低于4.50%(图6(c))。由于缺乏煤岩真实渗透率的测试结果,没有在Petrel内直接对渗透率进行建模。但可以根据孔隙度与渗透率之间的数学关系(式(1))[19-20],初步确定渗透率的分布情况。

$$ k = {k_{\text{b}}}{\left( {{\phi \mathord{\left/ {\vphantom {\phi {{\phi _{\text{a}}}}}} \right. } {{\phi _{\text{a}}}}}} \right)^3} $$ (1) 其中,$ k $为煤储层渗透率,10−15 m2;$ {k_{\text{b}}} $为煤储层基准渗透率,暂取10−15 m2;$ \phi $为煤储层孔隙度;$ {\phi _{\text{a}}} $为基准孔隙度,取0.05。由于渗透率与孔隙度呈立方关系,其与孔隙度的分布具有相同的特征(图6(d))。

煤岩弹性模量主要为2.50~3.50 GPa,平均2.80 GPa;高弹性模量主要分布于东部和南部边缘处,最大值超过3.60 GPa(图6(e))。泊松比主要为0.33~0.38,平均0.36;高值泊松比占据了模型的大部分区域,局部地区超过0.38,低值区呈零星斑状分布于模型的东北、东南、西南等区域(图6(f))。

1.3.2 重构模型检验

利用拆分−重构法在COMSOL Multiphysics内重构的煤储层三维非均质地质模型既能描述煤储层在地下空间的三维起伏情况,又能描述储层内属性参数的非均质变化情况。为了检验重构模型的准确性,将角点地质模型与重构地质模型的模型参数进行对比分析(表1)。结果显示2种模型中的煤储层厚度、CH4含气量、CH4吸附时间、孔隙度、渗透率、弹性模量和泊松比的最小值、最大值和平均值差异非常小或无差异,煤储层厚度、孔隙度、渗透率、弹性模量和泊松比的平均值相对误差为0,煤储层CH4含气量和CH4吸附时间的平均值相对误差分别为0.007%和0.070%,小于0.1%。这表明利用拆分−重构法构建的煤储层三维非均质地质模型能够高度还原基于Petrel平台建立的角点地质模型。

表 1 角点地质模型与重构地质模型参数对比Table 1. Parameter comparison between corner grid geological model and reconstructed geological model项目 模型来源 最小值 最大值 平均值 煤储层厚度/m 角点地质模型 4.912 7.304 6.259 重构地质模型 4.911 7.305 6.259 煤储层CH4含气量/(m3·t−1) 角点地质模型 5.927 25.639 14.119 重构地质模型 5.926 25.640 14.118 CH4吸附时间/d 角点地质模型 6.932 62.391 31.353 重构地质模型 6.930 62.391 31.331 孔隙度/% 角点地质模型 3.938 6.252 5.033 重构地质模型 3.937 6.253 5.033 渗透率/10−15 m2 角点地质模型 0.489 1.955 1.020 重构地质模型 0.488 1.956 1.020 弹性模量/GPa 角点地质模型 2.205 3.798 2.804 重构地质模型 2.205 3.799 2.804 泊松比 角点地质模型 0.326 0.384 0.359 重构地质模型 0.326 0.384 0.359 1.3.3 重构模型网格划分

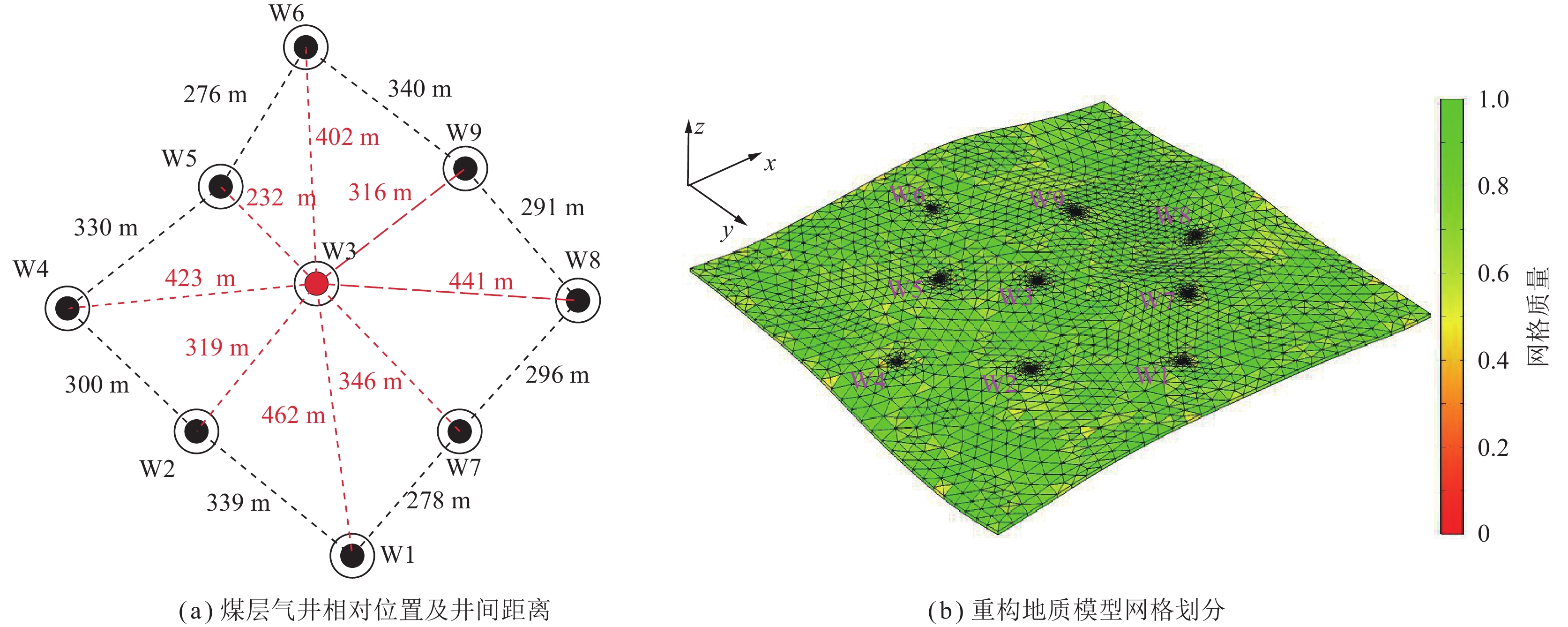

地质模型网格划分质量直接影响数值模拟结果的准确性、模型的运算速度以及计算机的内存需求,过于稀疏或过于密集的网格均不利于CO2-ECBM数值模拟工作的开展。以往模拟工作中,由于地质模型在几何上多为规则的二维矩形或三维长方体,属性上多为均质模型,常将地质模型进行对称简化,取整个模型的1/4进行网格划分[21-23]。然而,重构的煤储层地质模型垂向上呈三维起伏变化,储层内属性参数呈非均质分布,模型内有9口间距不等的煤层气井(图7(a)),使得在网格划分时不能将其进行对称简化。

根据重构地质模型的构造和属性特征及煤层气井的分布情况,在COMSOL Multiphysics软件内通过自由三角形和扫掠定义功能对其进行网格划分(图7(b))。定义自由三角形最小单元为尺寸0.02 m、最大单元尺寸为40 m,最大单元增长率为1.50,曲率因子0.60。经过网格划分后的重构地质模型拥有8 370个域单元、864个边单元、80个顶点单元;最小网格质量为0.40,平均网格质量为0.75。网格特征总表现为:在煤层气井附近较为密集,在模型边界处较为稀疏。重构模型的网格具有较高的质量和较少的网格数量,既能保证数值模拟结果的准确性,又能提高模型的运算速度和降低计算机的内存需求,有利于后续相关数值模拟研究的开展。

2. CO2-ECBM数值模拟

2.1 数学模型

当前,用于CO2-ECBM数值模拟研究的数学模型多为渗流−温度−应力(Hydraulic-Thermal-Mechanical,HTM)耦合模型[21-23],它可以有效描述CO2-ECBM过程中流体在煤储层内的赋存与运移以及煤储层温度与应力的状态变化。然而,HTM模型欠缺对CO2注入煤层后引发储层地球化学环境变化的考虑。在前人研究基础上,笔者使用一个自主推导且获得验证的能更全面表征CO2-ECBM过程的吸附−渗流−温度−应力−化学(Adsorption-Hydraulic-Thermal-Mechanical-Chemical,AHTMC)多场耦合模型[24]。该模型包含吸附场(A)、渗流场(H)、温度场(T)、应力场(M)、化学场(C)及储层孔−渗方程,不仅考虑了CO2-ECBM工程中煤储层内的气体吸附、流体渗流、温度和应力变化,还考虑了CO2注入煤储层后引起的一系列地球化学反应,如CO2在煤储层裂隙水中溶解形成的碳酸(H2CO3)电离生成碳酸氢根离子(${\rm{HCO}}_3^-$)与氢离子(H+)、碳酸氢根离子电离生成氢离子(H+)与碳酸根离子(${\rm{CO}}_3^{2-} $)、水电离生成氢离子(H+)与氢氧根离子(OH−)以及方解石在水中溶解生成碳酸根离子(${\rm{CO}}_3^{2-} $)与钙离子(Ca2+)(式(2))。同时,该模型还能够描述这些化学离子在储层裂隙水内的运移(式(3))。

$$ \left\{ \begin{gathered} {{\text{H}}_{\text{2}}}{\text{C}}{{\text{O}}_{\text{3}}} \rightleftharpoons}_{\text{3}}^{{ - }} \\ {\text{HCO}}_{\text{3}}^{{ - }} \rightleftharpoons}_{\text{3}}^{{{2 - }}} \\ {{\text{H}}_{\text{2}}}{\text{O}} \rightleftharpoons}{{\text{H}}^{{ - }}} \\ {\text{CaC}}{{\text{O}}_{\text{3}}}{\text{(calcite)}} \rightleftharpoons}{{\text{a}}^{{\text{2+ }}}} \\ \end{gathered} \right. $$ (2) $$ \frac{{\partial {\text{(}}{C_{{j}}}{S_{\text{w}}}\phi {\text{)}}}}{{\partial t}} + \nabla \cdot \left( {{C_{{j}}}{v_{\text{w}}} - \tau \phi {S_{\text{w}}}{D_{{j}}}\nabla {C_{{j}}}} \right) = {Q_{{j}}} $$ (3) 式中,${C_{{j}}}$为化学离子组分$j$在裂隙水中的浓度,mol/m3;$ {S_{\text{w}}} $为裂隙含水饱和度;$ t $为时间,d;$ {v_{\text{w}}} $为水的渗流速度,m/s;$ \tau $为孔隙迂曲度;$ {D_{{j}}} $为化学离子组分$j$在水中的扩散系数,m2/s;$ {Q_{{j}}} $为化学反应源汇相,mol/(m3·s)。

此外,CH4、CO2和水在储层内赋存与运移时,储层孔隙度与渗透率呈动态变化。随着气体在煤基质内吸附/解吸、储层压力动态变化、储层温度波动以及方解石溶解/沉淀,煤储层孔隙度和渗透率的变化规律可以表示为

$$\left\{ \begin{gathered} \phi = \frac{1}{{1 + S}}\left[ {\left( {1 + {S_0}} \right){\phi _0} + \alpha \left( {S - {S_{ 0}}} \right)} \right] \\ {S_{ 0}} = {\varepsilon _{{\text{v0}}}} - \frac{{{P_{{\text{f0}}}}}}{{K_{\text{s}}}} - {\varepsilon _{{\text{s0}}}} - {\alpha _{\text{T}}}{T_0} - \frac{{{\varepsilon _{{\text{m0}}}}{M_{{\text{vm}}}}}}{{1 - {\phi _0}}} \\ S = {\varepsilon _{\text{v}}} - \frac{{{P_{\text{f}}}}}{{K_{\text{s}}}} - {\varepsilon _{\text{s}}} - {\alpha _{\text{T}}}T - \frac{{{\varepsilon _{\text{m}}}{M_{{\text{vm}}}}}}{{1 - \phi }} \\ k = {k_0}{\left( {\frac{\phi }{{{\phi _0}}}} \right)^3} \\ \end{gathered} \right. $$ (4) 式中,$ \alpha $为Biot有效应力系数;$ {\varepsilon _{\text{v}}} $为煤储层应变;下角0代表初始状态;$ {P_{\text{f}}} $为煤储层孔隙压力,MPa;$ K_{\text{s}} $为煤基质块体积模量,GPa;$ {\varepsilon _{\text{s}}} $为煤基质吸附气体膨胀应变;$ {\alpha _{\text{T}}} $为煤岩热膨胀系数,K−1;$ T $为储层温度,K;$ {\varepsilon _{\text{m}}} $为储层固体部分方解石浓度,mol/m3;$ {M_{{\text{vm}}}} $为方解石摩尔体积,m3/mol。

2.2 关键参数与模拟方案

2.2.1 关键参数

笔者使用的关键参数主要源于工程测试、室内实验和前人研究文献。根据室内实验测试,沁水盆地3号煤储层CO2兰氏体积约为CH4兰氏体积的1.8倍,CO2初始吸附时间约为CH4初始吸附时间的1.5倍。同时,假设储层CH4含气量的非均质分布受煤基质对气体吸附能力的非均质性控制。用于数值模拟研究的其他关键参数见表2。

关键参数 数值 关键参数 数值 初始温度/K 298.15 孔径分布指数 1.00 初始H+浓度/(mmol·L−1) 4.57×10−6 煤岩密度/(kg·m−3) 1450 初始${\rm{HCO}}_3^- $浓度/(mmol·L−1) 5.76 水的密度/(kg·m−3) 1000 初始${\rm{CO}}_3^{2-} $浓度/(mmol·L−1) 1.40×10−2 有效应力系数 0.50 初始OH−浓度/(mmol·L−1) 2.19×10−3 CH4导热系数/(W·(m·K)−1) 3.01×10−2 初始Ca2+浓度/(mmol·L−1) 0.32 CO2导热系数/(W·(m·K)−1) 1.37×10−2 CH4兰氏压力/MPa 2.15 水导热系数/(W·(m·K)−1) 5.99×10−2 CO2兰氏压力/MPa 1.40 煤岩导热系数/(W·(m·K)−1) 0.19 压力系数/MPa−1 7.1×10−2 CH4比热容/(kJ·(kg·K)−1) 2.22 温度系数/K−1 2.10×10−2 CO2比热容/(kJ·(kg·K)−1) 0.84 CH4动力黏度/(Pa·s) 1.34×10−5 水比热容/(kJ·(kg·K)−1) 4.19 CO2动力黏度/(Pa·s) 1.84×10−5 煤比热容/(kJ·(kg·K)−1) 1.35 水动力黏度/(Pa·s) 1.01×10−5 CH4吸附热/(kJ·mol−1) 16.40 CH4指数常数 −15.07 CO2吸附热/(kJ·mol−1) 19.20 CO2指数常数 −12.46 CH4溶解热/(kJ·mol−1) 14.12 CH4温度常数/K 1 545.00 CO2溶解热/(kJ·mol−1) 19.99 CO2温度常数/K 2 258.50 残余水饱和度 0.05 标准温度/K 273.15 残余气饱和度 0 标准压力/MPa 1.01×10−2 方解石中性活化能/(kJ·mol−1) 23.50 CH4扩散活化能/(kJ·mol−1) 34.00 方解石酸性活化能/(kJ·mol−1) 14.40 CO2扩散活化能/(kJ·mol−1) 18.00 中性反应速率常数/(mol·(m2·s)−1) 1.55×10−6 摩尔气体常数/(J·(mol·L)−1) 8.31 酸性反应速率常数/(mol·(m2·s)−1) 0.50 气体滑脱系数/MPa 0.75 方解石比表面积/(m2·kg−1) 9.8×10−3 排驱压力/MPa 1.00×10−2 方解石密度/(kg·m−3) 2710 2.2.2 数值模拟方案

CO2-ECBM工程开展前各煤层气井已经开采多年,且前述构建的三维非均质地质模型中缺少准确的渗透率。在开展CO2-ECBM数值模拟研究前,有必要通过生产历史拟合确定真实的储层初始渗透率,并进一步检验三维非均质地质模型和AHTMC数学模型的准确性。基于此分析,根据工程先后顺序将整个模拟分为生产历史拟合和CO2-ECBM模拟2个阶段(表3)。由于煤储层含气量、孔隙度和渗透率等经过多年生产后已经发生很大变化,在CO2-ECBM模拟时需要继承生产历史拟合的地质模型。

表 3 数值模拟方案Table 3. Scheme for numerical simulation模拟阶段 排采压力/MPa 注入井 CO2注入压力/MPa CO2注入温度/℃ 模拟时长/a 生产历史拟合 实测 — — — 实测 CO2-ECBM模拟 0.1 W3 5.5、6.5、7.5、8.5、9.5 20 15 2.3 生产历史拟合结果与分析

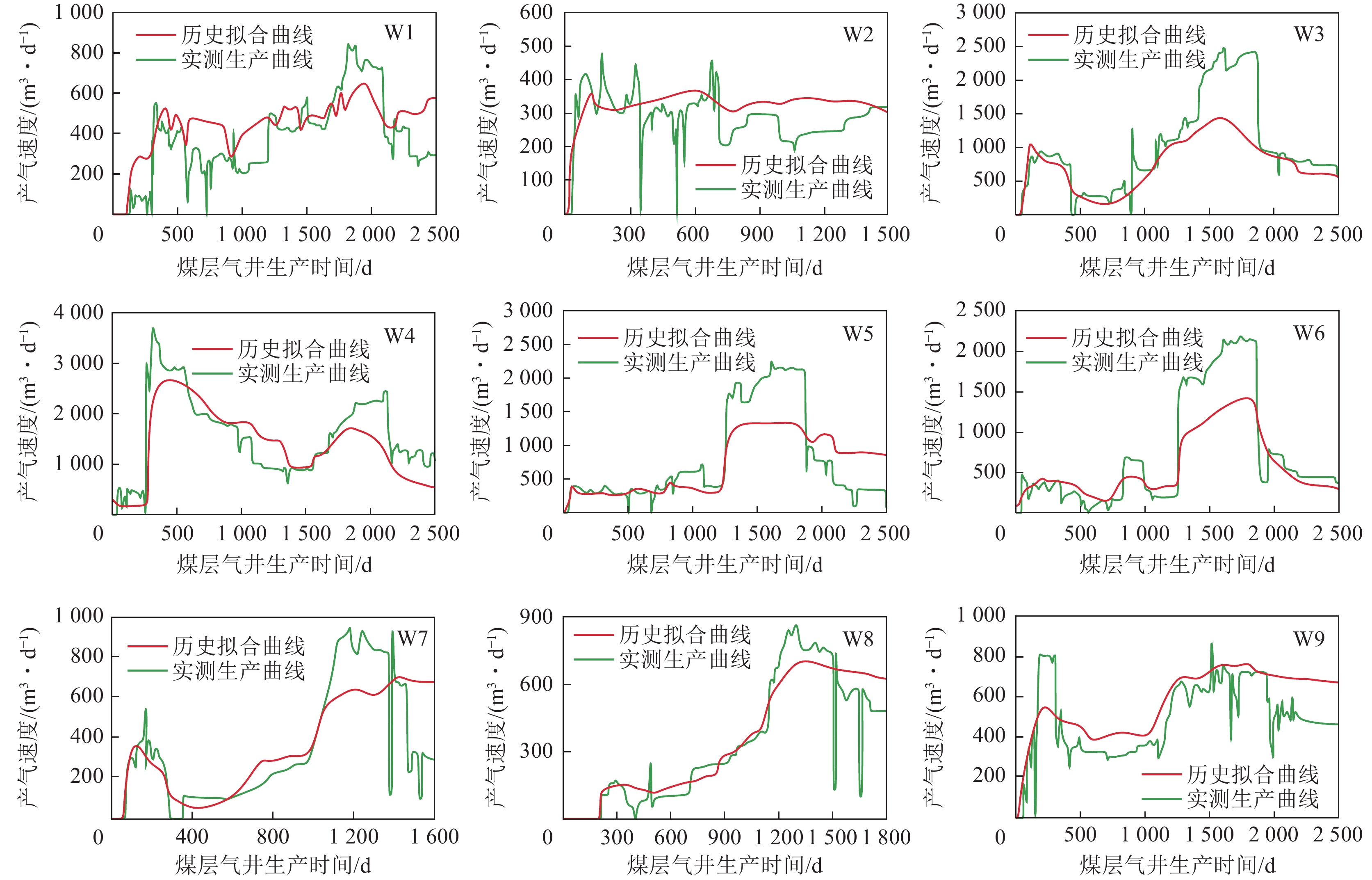

图8展示了各煤层气井CH4实测产气速度和模拟产气速度的对比情况。各井CH4的生产拟合曲线均能够较好地匹配实测生产曲线,拟合误差为7.56%~18.67%,平均为12.14%。拟合效果最好的井为W8井,该井在约1 100 d之前产气速度低于500 m3/d,1 100 d后产气速度快速增加至约900.00 m3/d后逐渐降低。煤层气井的生产历史拟合结果表明,构建的三维非均质地质模型和AHTMC多场耦合数学模型对柿庄南煤储层的三维空间展布、属性参数分布和储层内气体吸附、渗流等规律的描述较为准确。

CH4生产历史拟合是根据收集到的生产排采数据,通过调整式(1)中的基准值$ {k_{\text{b}}} $进行的。当$ {k_{\text{b}}} $取1.146×10−15 m2时,基于数值模拟获得的煤层气井CH4产气速度与实测产气速度的变化趋势基本一致,误差较小(图8)。此时,煤储层初始渗透率为0.488 5×10−15~2.252 2×10−15 m2,平均1.165×10−15 m2(图9)。

2.4 CO2-ECBM模拟结果与分析

2.4.1 CH4生产与增产

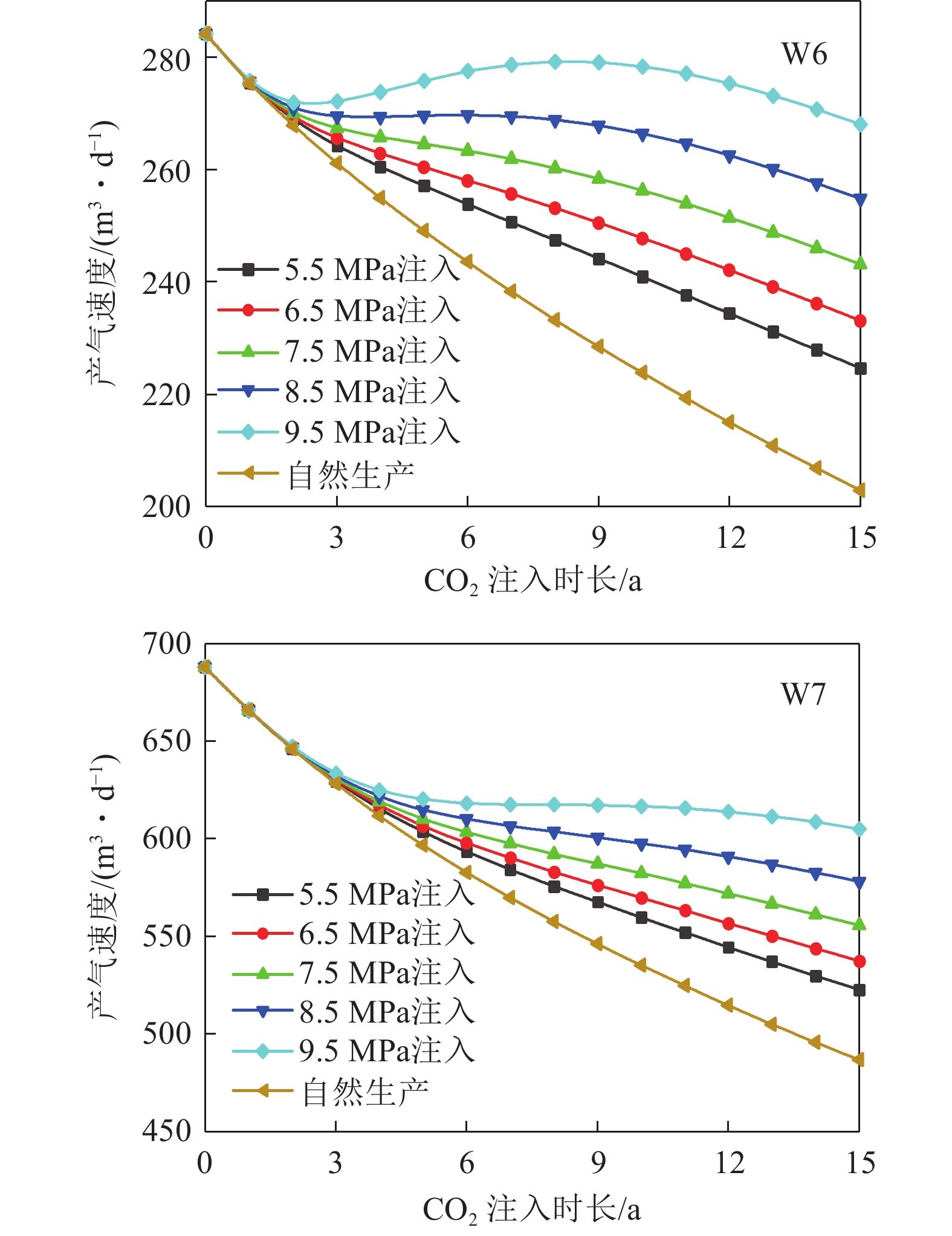

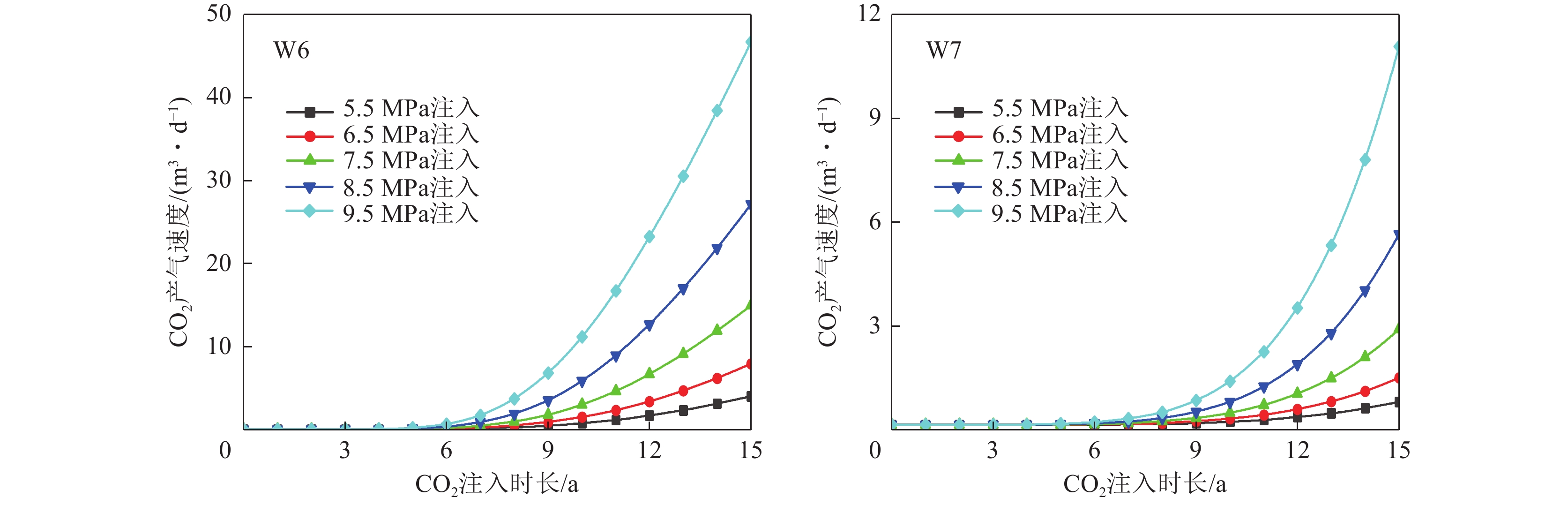

图10展示了自然生产和向煤储层注CO2时W6和W7井的CH4产气速度变化情况。在自然生产情况下,W6和W7井CH4产气速度均表现出随生产时间延长而逐渐降低的变化趋势。与自然生产相比,2口井的CH4产气速度在CO2注入初期没有明显提升,随着时间的延长,其数值逐渐增加,且增幅不断变大。当较自然生产有明显提升后,W6和W7井的CH4产气速度随CO2注入压力的增加而显著升高。此外,与W7井相比,W6井的CH4产气速度明显偏低,这主要是由于煤储层CH4含气量、孔隙度和渗透率的非均质分布造成的。W6井所处位置及周围煤储层CH4含气量、孔隙度和渗透率远小于W7井,缺乏充足的CH4气源和较好的渗流通道。

表4展示了CO2-ECBM工程实施15 a后不同CO2注入压力下生产井组CH4增产情况。5.50~9.50 MPa注气压力下,CH4增产率为4.93%~14.39%。随着CO2注入压力的增加,CH4增产量及增产率均显著增加。这表明,在CO2-ECBM过程中,较高的CO2注入压力更有利于CH4增产。

表 4 不同注入压力下井组CH4增产情况Table 4. CH4 stimulation of well group under different injection pressuresCO2注入压力/MPa 5.5 6.5 7.5 8.5 9.5 CH4增产量/106 m3 1.11 1.52 2.00 2.57 3.23 CH4增产率/% 4.93 6.76 8.93 11.46 14.39 2.4.2 CO2注入与封存

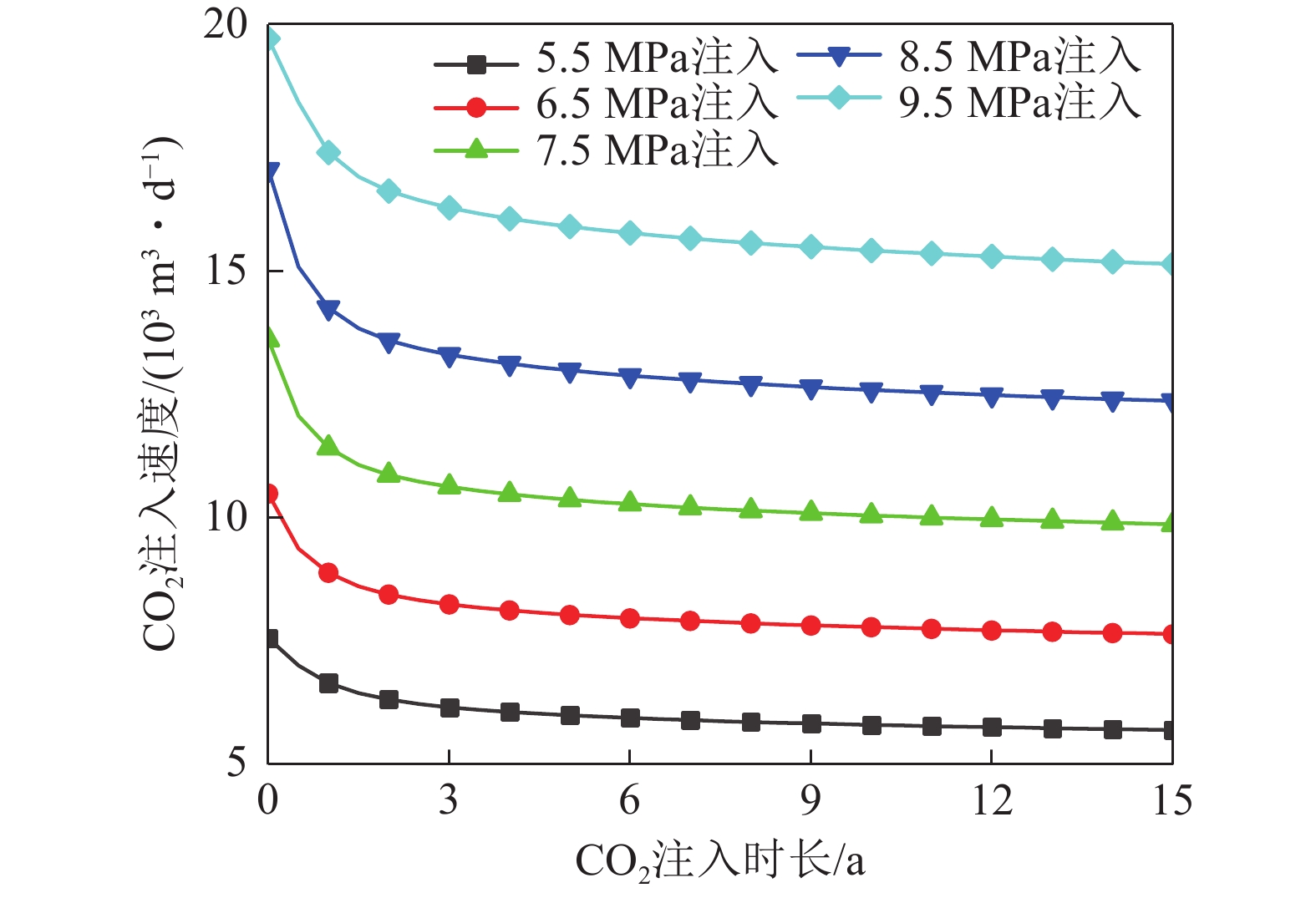

图11展示了在不同注气压力下注入井W3的CO2注入速度变化情况。总体上,CO2注入速度表现为随注气压力的增加而升高,随注入时间的延长先逐渐降低再趋于稳定。根据达西定律,储层内流体运移速度主要受控于流体压力梯度和渗透率。CO2-ECBM过程中,CO2注入压力越大,则储层内的CO2压力梯度越大,使得CO2的渗流速度越大;吸附于煤基质的CO2诱导煤岩膨胀,随着时间的延长,煤基质膨胀逐渐增加并趋于稳定,导致储层孔隙度和渗透率逐渐降低并趋于稳定。

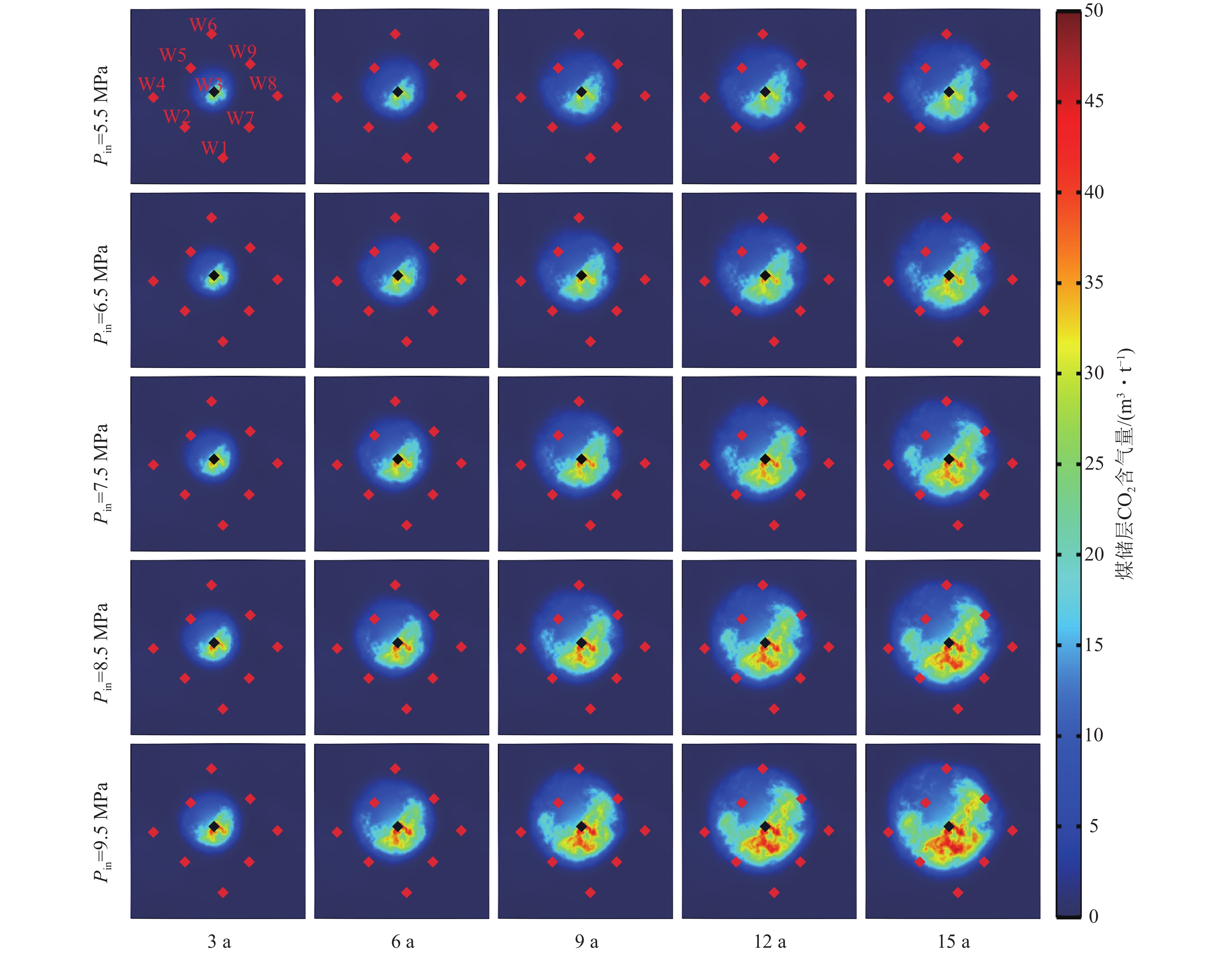

经W3井注入煤储层的CO2大部分吸附于煤基质内。图12展示了不同CO2注入压力(Pin)下的煤储层基质内CO2含气量的动态变化情况。由于煤岩对气体的吸附能力是非均质的,储层基质内的CO2含气量在CO2-ECBM过程中是呈非均质分布的。随着时间的延长和CO2注入压力的增加,煤基质内CO2含气量逐渐增加并由注入井向周围不断扩展,高含气量区域面积(35~50 m3/t)也不断扩大。

部分注入煤储层的CO2在压力驱动下经裂隙运移至生产井井底并产出,图13展示了W6和W7井CO2产气速度变化情况。在CO2注入的初始6 a内,2口井几乎没有CO2产出,这是由于注入储层的CO2大部分被煤基质吸附。此后,随着注入时间的延长,W6和W7井CO2产气速度逐渐增加,并随着注气压力的增加而升高。此外,2口井的CO2产气速度存在明显差异,同一时刻W6井的CO2产气速度明显高于W7井,这主要是由煤储层的非均质性造成的。三维空间上,2口井与注入井W3所处位置的煤层倾角非常小,基本处于同一水平;平面上,W6与W3的距离较W7与W3的距离更远一些,如果没有储层非均质性的影响,相同时刻W6的CO2生产速度应该偏低[24]。然而,受W7所处位置周围煤储层对气体吸附能力较W6井高出很多的影响,CO2在向W7井运移的过程中会被煤基质大量吸附,促使W7井的CO2产气速度低于W6井。

注入压力对注入井CO2注入速度和生产井CO2产出速度的影响直接控制CO2在煤储层内的封存。CO2-ECBM工程实施15 a后,随着CO2注入压力的增加,CO2累计注入量、累计产出量以及封存量均增加,最大可分别达约8.71×107、3.95×106、8.31×107 m3。受CO2从生产井产出的影响,CO2封存率随注气压力增加而减小,但各注气压力下其均保持在95%以上(表5)。这表明,柿庄南3号煤储层拥有较好的CO2封存能力,低压注入有利于提高CO2在煤储层内的封存率,高压注入有利于提高CO2在煤储层内的封存量。

表 5 煤储层CO2注入与封存情况Table 5. CO2 injection and storage of coal reservoir注入压力/MPa 累计注入量/m3 累计产出量/m3 封存量

/m3封存率/% 5.5 32 853 745 745 129 32 108 616 97.73 6.5 44 035 152 1 208 946 42 826 206 97.25 7.5 56 801 441 1 863 003 54 938 437 96.72 8.5 71 155 914 2 757 821 68 398 093 96.12 9.5 87 100 860 3 953 589 83 147 271 95.46 2.4.3 煤储层地球化学环境变化

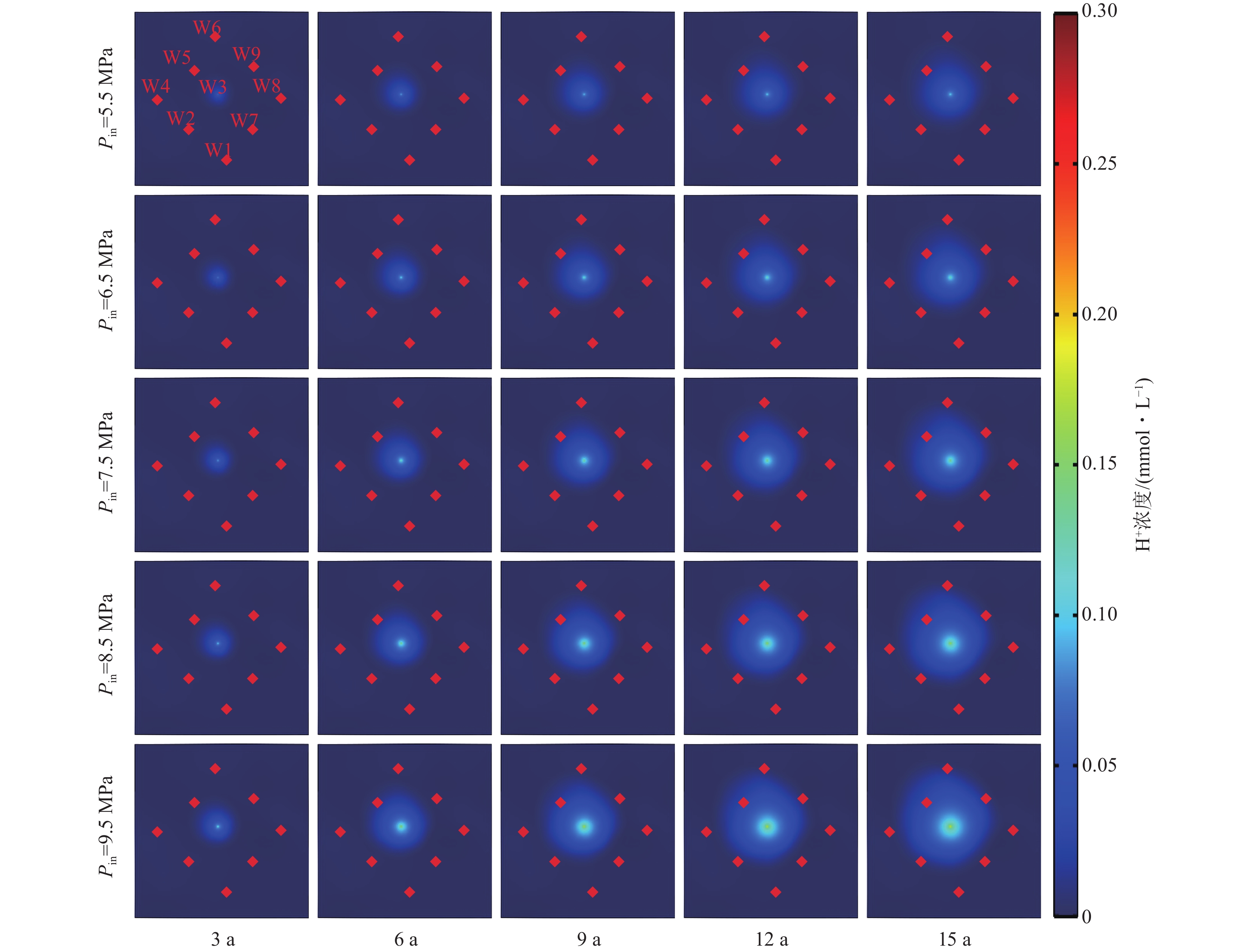

部分注入煤储层的CO2会溶解于裂隙水中,并与水中已有的离子发生化学反应,改变储层的地球化学环境。H+浓度常被用于判断煤储层裂隙水的酸碱性,298.15 K时,当H+浓度超过1.0×10−7 mol/L时,裂隙水呈碱性;当H+浓度小于1.0×10−7 mol/L时,裂隙水呈酸性。图14展示了不同CO2注入压力下储层内H+浓度的变化情况。相较于初始裂隙水的碱性环境(H+初始浓度为4.57×10−9 mol/L),注入井附近储层裂隙水在CO2注入后快速转变为酸性(H+浓度大于5.0×10−5 mol/L),且随CO2注入压力的升高,含酸性裂隙水的煤储层范围逐渐增大。随着时间的延长,含酸性裂隙水的煤储层区域不断向外扩展并逐渐波及到生产井,可以预见,生产井产出水中的H+浓度也会逐渐增加,需要对其进行处理才能排放。

3. CO2注入优化

CO2-ECBM的主要目的是提高煤层气井CH4产量并将CO2封存于煤储层中。在实际工程中,随着生产井产出气中CO2体积分数不断增加,CO2封存效果会逐渐变差[25-26],不得不关闭生产井。此外,煤层气井的寿命存在上限,并非无限延长。这些使得CO2-ECBM的工程效果会受到一定制约。因此,需要结合时间因素,综合CH4增产和CO2封存效果,优化CO2注入以促使CO2-ECBM的工程效果达到最优。

3.1 注入优化方法

3.1.1 目标函数构建

工程耗时、CH4增产和CO2封存是评价CO2-ECBM工程效果的基本指标。一般情况下,工程耗时越短、CH4产量越大、CO2封存量和封存率越大,CO2-ECBM工程效果越好。基于此,构建包含工程时间(CO2开始注入煤储层至所有生产井关闭时CO2-ECBM工程所消耗的时间)、CH4产气量、CO2封存量和封存率等指标在内的目标函数用以评价CO2-ECBM工程效果(式(5)):

$$ \begin{split} {V_{\text{a}}} =& - {\beta _1}\left[ {\frac{{{t_{\text{p}}} - {\text{min}}\left( {{t_{\text{p}}}} \right)}}{{{\text{max}}\left( {{t_{\text{p}}}} \right) - {\text{min}}\left( {{t_{\text{p}}}} \right)}}} \right] + {\beta _2}\left[ {\frac{{{q_{\text{p}}} - {\text{min}}\left( {{q_{\text{p}}}} \right)}}{{{\text{max}}\left( {{q_{\text{p}}}} \right) - {\text{min}}\left( {{q_{\text{p}}}} \right)}}} \right] +\\ & \frac{{{\beta _3}}}{2}\left[ {\frac{{{q_{\text{s}}} - {\text{min}}\left( {{q_{\text{s}}}} \right)}}{{{\text{max}}\left( {{q_{\text{s}}}} \right) - {\text{min}}\left( {{q_{\text{s}}}} \right)}} + \frac{{{r_{\text{s}}} - {\text{min}}\left( {{r_{\text{s}}}} \right)}}{{{\text{max}}\left( {{r_{\text{s}}}} \right) - {\text{min}}\left( {{r_{\text{s}}}} \right)}}} \right] \end{split} $$ (5) 其中,$ {V_{\text{a}}} $为CO2-ECBM工程效果值;$ {t_{\text{p}}} $为CO2-ECBM工程时间,d;$ {q_{\text{p}}} $为CH4产气量,m3;$ {q_{\text{s}}} $为CO2封存量,m3;$ {r_{\text{s}}} $为CO2的封存率,%;${\left[ {a - {\text{min}}\left( a \right)} \right]} \mathord{\left/ {\vphantom {{\left[ {a - {\text{min}}\left( a \right)} \right]} {\left[ {{\text{max}}\left( a \right) - {\text{min}}\left( a \right)} \right]}}} \right. } \left[ {\text{max}}\left( a \right) - {\text{min}}\left( a \right) \right]$为对基本指标$ a $进行线性归一化,以便统一所有指标的单位[27];$ {\beta _1} $、$ {\beta _2} $、$ {\beta _3} $分别为工程时间、CH4生产、CO2封存的权重系数,$ {\beta _1} + {\beta _2} + {\beta _3} = 1 $。在相同的权重系数下,$ {V_{\text{a}}} $越大表示CO2-ECBM工程效果越好。结合CO2-ECBM工程对时效性、CH4增产和CO2封存3个基本指标的侧重,定义4种CO2-ECBM工程目标:① 省时提效、CH4增产和CO2封存综合兼顾;② 省时提效;③ CH4增产;④ CO2封存。其目标函数对应的各参数权重取值见表6。

表 6 目标函数权重系数Table 6. Weight coefficient of objective function工程目标 β1 β2 β3 综合兼顾 1/3 1/3 1/3 省时提效 3/5 1/5 1/5 CH4增产 1/5 3/5 1/5 CO2封存 1/5 1/5 3/5 3.1.2 样本采集

研究区煤储层局部地区的最小主应力不超过9.5 MPa,持续高压注入CO2很可能会压裂煤储层并在注入井和生产井间建立高渗通道,导致注入煤储层的CO2沿裂缝直接运移至生产井并产出[28]。而过低的注气压力不能有效将CO2注入煤储层,无法取得较好的CO2-ECBM工程效果。笔者将CO2注入压力限制在3.50~9.50 MPa。除选择3.50、4.50、5.50、6.50、7.50、8.50、9.50 MPa等7个注气压力外,还利用均匀随机分布函数模拟产生了30个3.50~9.50 MPa的其他注气压力。

3.1.3 关井方式

由于研究区井组有8口生产井,有必要确立生产井的关井方案。笔者以生产井产出气中CO2体积分数达到10%为阈值设立以下2种关井方式:① 同时关井,指以整个研究区8口生产井为研究对象,当8口产气井瞬时累计产出气的CO2体积分数达到10%时,同时关闭所有井;② 序贯关井,指在CO2-ECBM过程中单井产出气中CO2体积分数达到10%时,关闭该生产井,当所有生产井都关闭后,CO2-ECBM工程结束。

3.2 同时关井CO2注入优化

3.2.1 井组产出气CO2体积分数与CH4产气速度

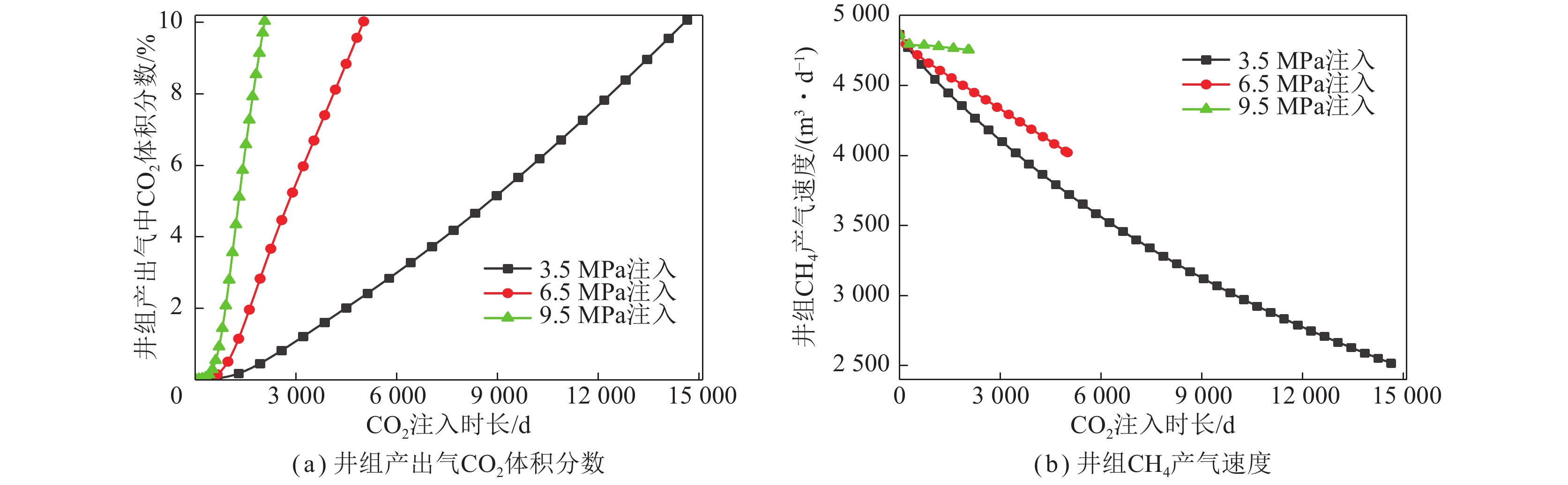

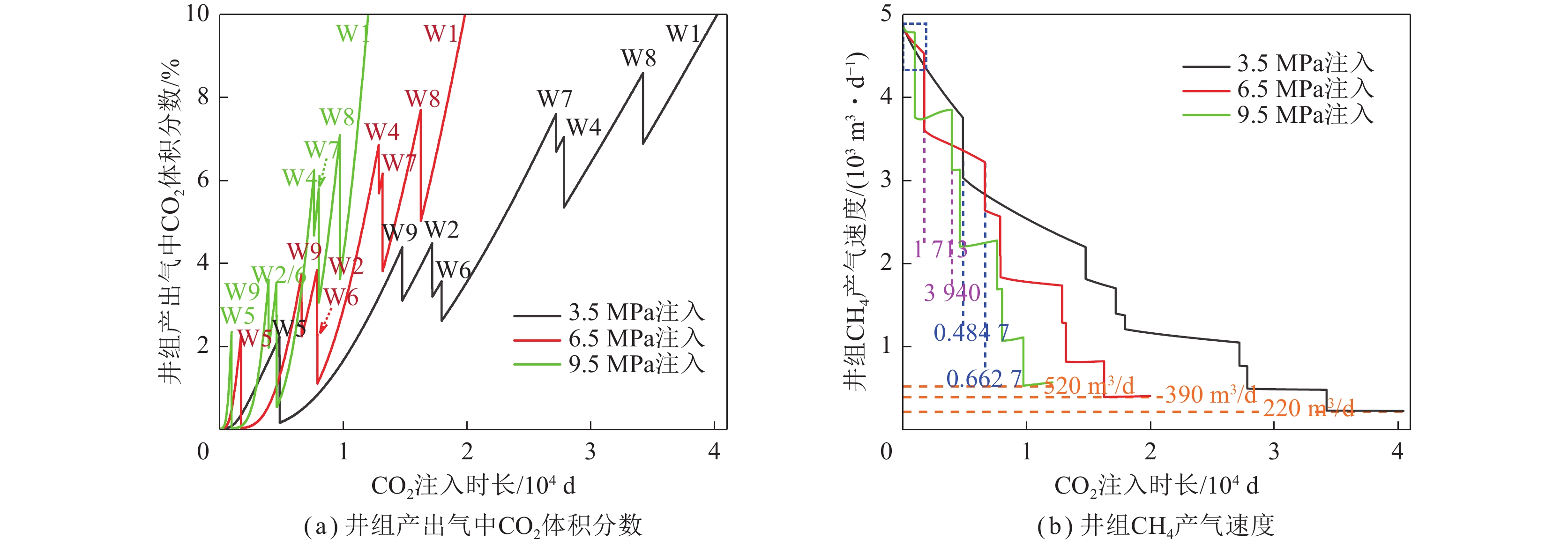

同时关井方式下,CO2注气压力对生产井组产出气中CO2体积分数变化影响较大。当CO2从生产井产出后,井组产出气中CO2体积分数随注气时间延长不断增加,并随CO2注入压力增加而升高(图15(a))。至井组产出气中CO2体积分数达到10%时,CO2注入时间由小到大对应的注气压力依次为9.5、6.5、3.5 MPa。

CO2注气压力的差异也影响生产井组CH4的生产。图15(b)展示了3.5、6.5和9.5 MPa注气压力下研究区生产井组CH4产气速度随CO2注气时间的变化情况。随CO2注气时间延长,井组CH4产气速度逐渐降低;随着CO2注气压力增加,井组CH4产气速度升高。至CO2-ECBM工程结束时,3.5、6.5和9.5 MPa注气压力下的井组CH4产气速度分别约为4 750、4 000和2 500 m3/d,即单井平均CH4产气速度分别约为593.75、500.00和312.50 m3/d。

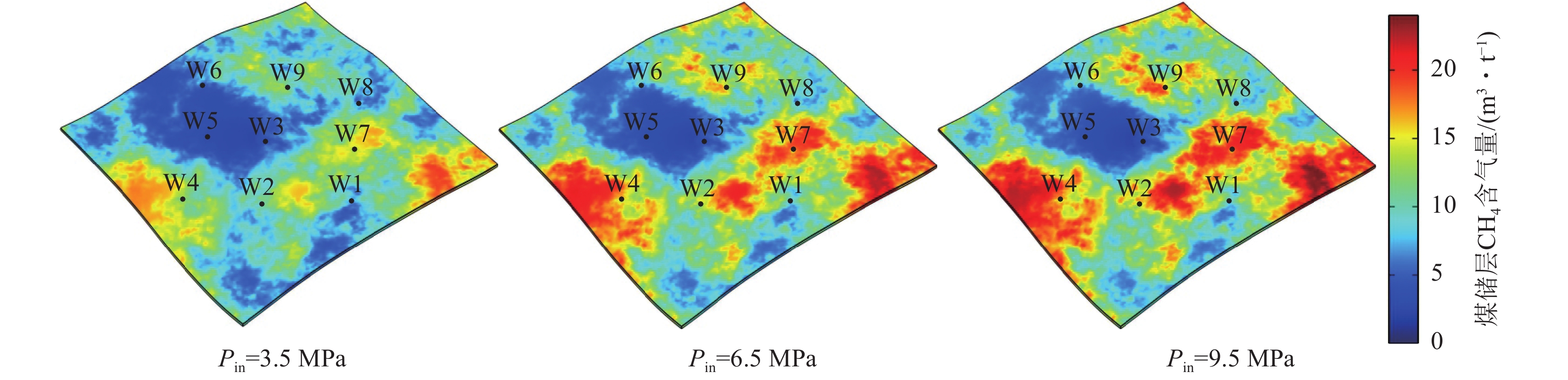

图16展示了3.5、6.5和9.5 MPa注气压力下CO2-ECBM工程结束时煤储层CH4含气量分布情况。受煤岩吸附气体非均质性的影响,储层CH4含气量在煤储层内呈非均质分布,数值范围随CO2注气压力的增加而扩大。工程结束时,3.5、6.5和9.5 MPa注气压力下的储层CH4含气量分别为0.63~19.47、0.63~22.80、0.63~24.01 m3/t,平均值分别为9.42、11.45、12.31 m3/t。根据初始和工程结束时煤储层CH4含气量的数值,可以计算出3.5、6.5和9.5 MPa注气压力下储层煤层气采收率分别为33.28%、18.90%和12.81%,即CH4采收率随注气压力增加而降低。

3.2.2 基本指标拟合

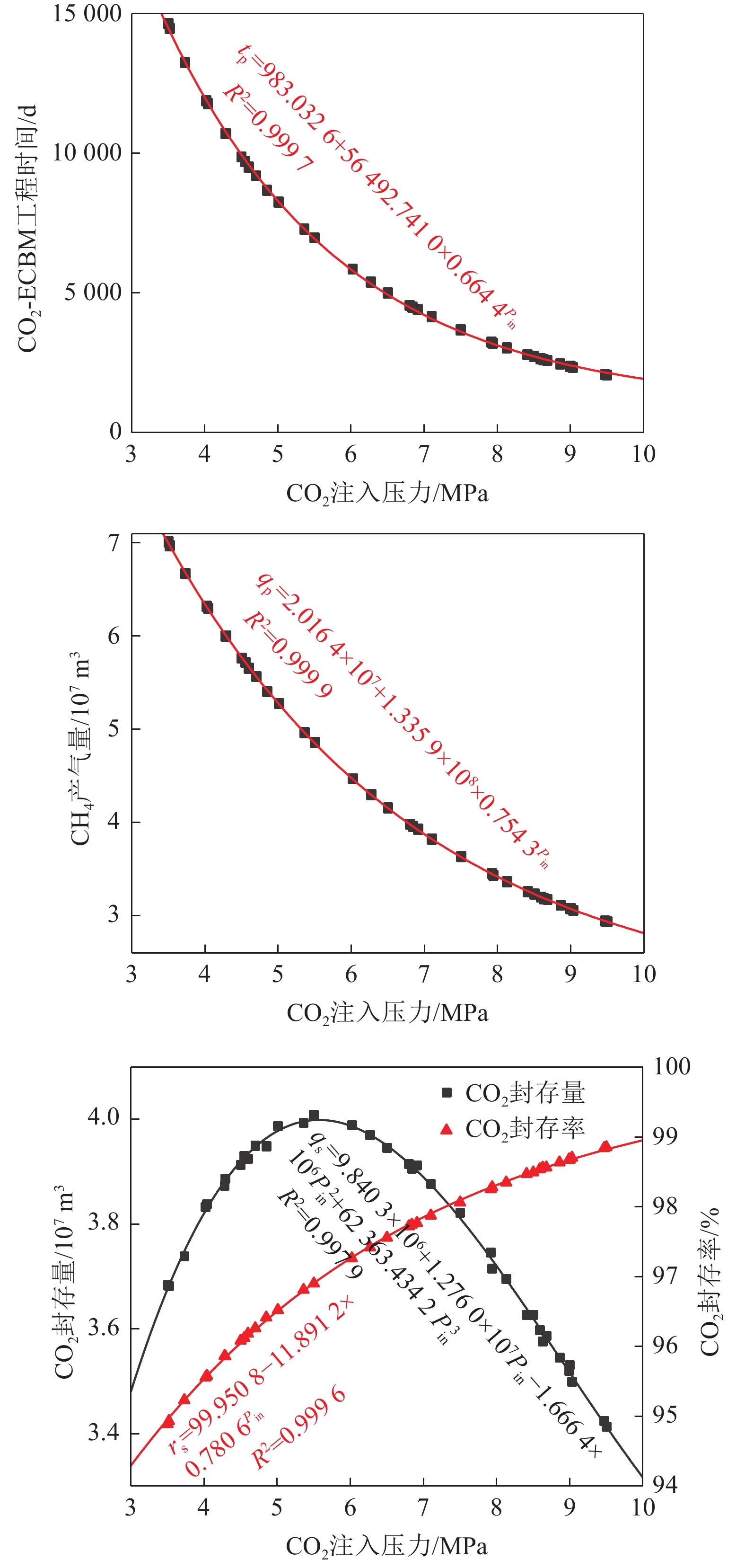

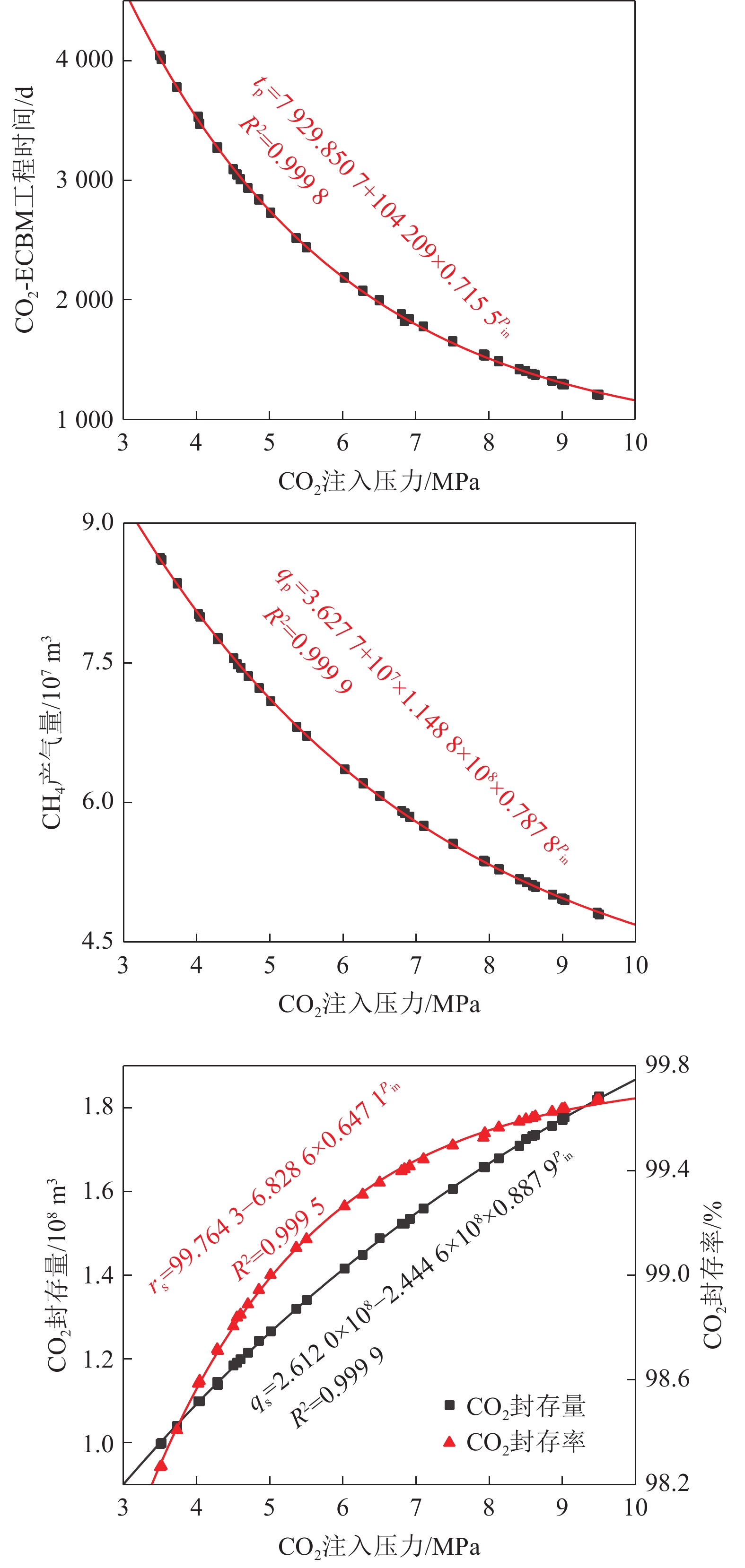

图17展示了研究区同时关井方式下CO2-ECBM工程时间、CH4产气量、CO2封存量和封存率随注气压力的变化情况。随着CO2注入压力的增加,工程时间、CH4产气量和CO2封存率逐渐升高,而CO2封存量则先增加后减小。它们之间的关系可以用指数或多项式函数进行表征:

$$ \left\{ \begin{array}{l} {t_{\text{p}}} = {\text{983}}{\text{.032 6}} + {\text{56 492}}{\text{.741 0}} \times {\text{0}}{\text{.664 }}{{\text{4}}^{{P_{{\text{in}}}}}} \\ {q_{\text{p}}} = {\text{2}}{\text{.016 4}} \times {10^7} + {\text{1}}{\text{.335 9}} \times {10^8} \times {\text{0}}{\text{.754 }}{{\text{3}}^{{P_{{\text{in}}}}}} \\ {q_{\text{s}}} = {\text{9}}{\text{.840 3}} \times {10^6} + {\text{1}}{\text{.276 0}} \times {10^7}{P_{{\text{in}}}} -\\ \qquad{\text{1}}{\text{.666 4}} \times {10^6}{P_{{\text{in}}}^2} + {\text{62 363}}{\text{.434 2}}{P_{{\text{in}}}^3} \\ {r_{\text{s}}} = {\text{99}}{\text{.950 8}} - {\text{11}}{\text{.891 2}} \times {\text{0}}{\text{.780 }}{{\text{6}}^{{P_{{\text{in}}}}}} \\ \end{array} \right. $$ (6) 3.2.3 CO2注气压力优化

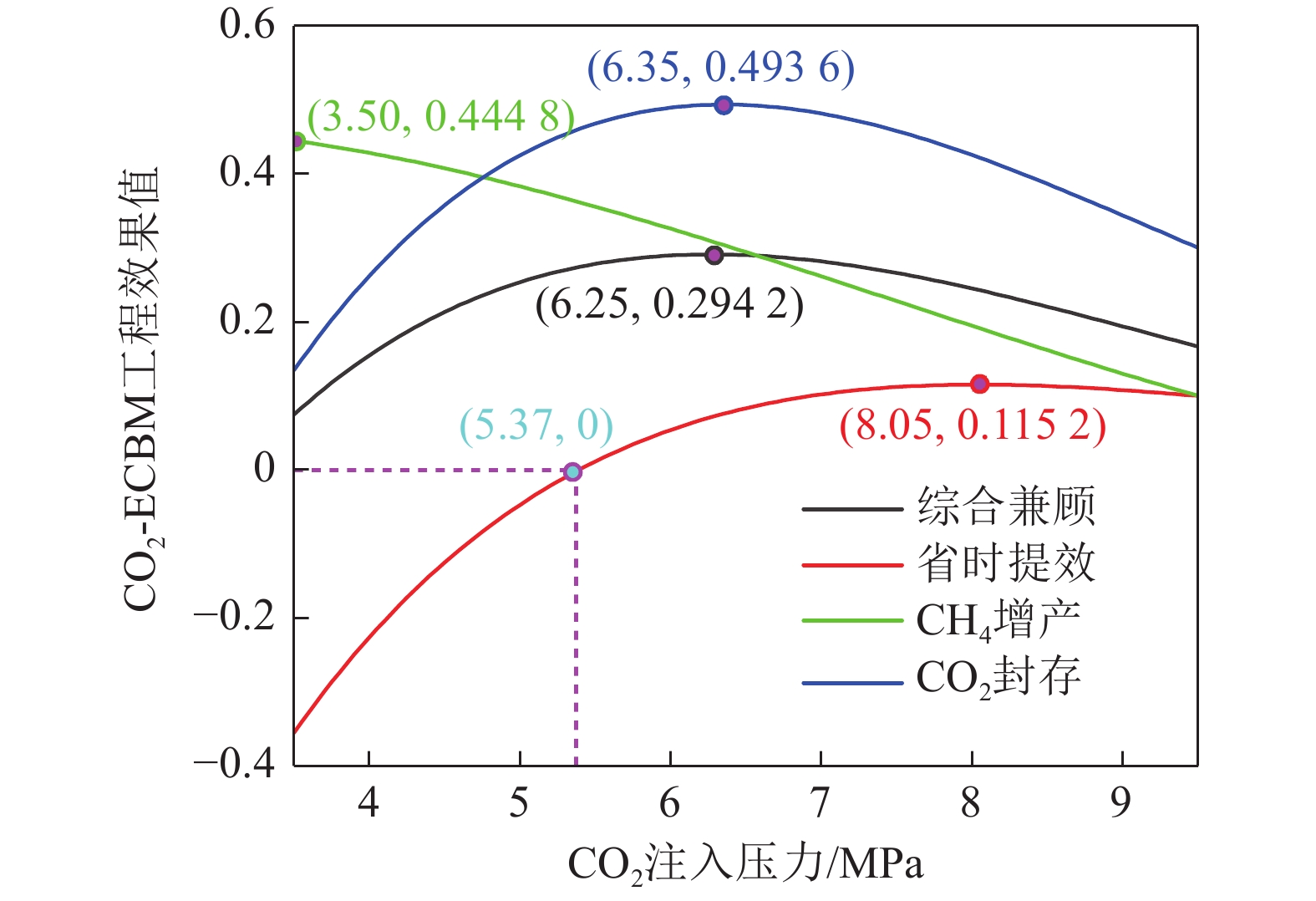

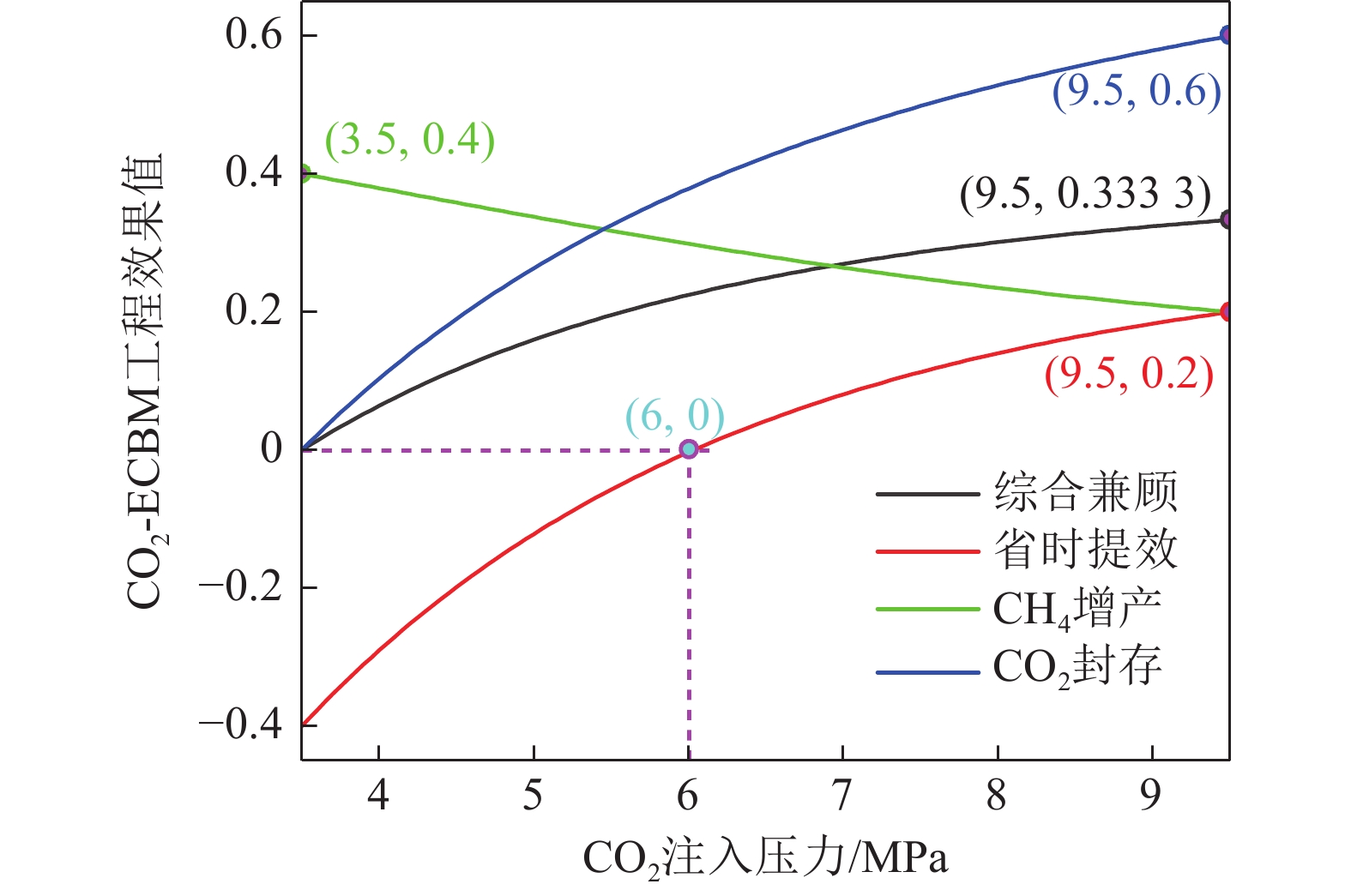

图18展示了基于式(5)和式(6)计算的同时关井情况下4种目标的工程效果值随CO2注入压力变化情况。以综合兼顾、省时提效和CO2封存为目标的工程效果值随CO2注入压力增加先升高后降低;以CH4增产为目标的效果值则随CO2注入压力增加持续减小。此外,以省时提效为目标的效果值在注气压力5.37 MPa以下时小于0,说明采用低压向煤储层注入CO2不会取得好的省时提效工程效果。在实际CO2-ECBM工程中,对CO2注入压力的控制不可能非常精细,以0.05 MPa为基础变量求取最优CO2注入压力。结果显示,综合兼顾、省时提效、CH4增产和CO2封存对应的最优CO2注入压力分别为6.25、8.05、3.50和6.35 MPa。

3.3 序贯关井CO2注入优化

3.3.1 井组产出气CO2体积分数与CH4产气速度

序贯关井方式下,生产井内CO2体积分数达到10%即会被关闭,导致生产井组产出气的CO2体积分数在CO2-ECBM过程中剧烈波动(图19(a))。在整个工程周期内,CO2注入压力为3.5和6.5 MPa时,井组共发生8次关井,3.5 MPa下生产井关井顺序为W5→W9→W2→W6→W7→W4→W8→W1,6.5 MPa下生产井关井顺序为W5→W9→W2→W6→W4→W7→W8→W1;CO2注入压力为9.5 MPa时,井组共发生7次关井,生产井关井顺序为W5→W9→W2/6(W2和W6同时关井)→W4→W7→W8→W1。序贯关井方式的关井特征表明CO2注气压力对CO2-ECBM过程中生产井组的关井次数和顺序存在影响。

序贯关井方式下CO2-ECBM过程中生产井的关闭直接影响井组CH4产气速度变化(图19(b))。与同时关井相似,序贯关井时井组CH4产气速度总体上也呈现出随CO2注入时间增加而降低的变化趋势。然而,序贯关井方式下井组CH4产气速度的变化是更复杂的,生产井每关闭一次,井组CH4生产速度就会下降一次,且低压注入下的CH4产气速度总体上高于高压注入的情况。值得注意的是,当井组内有效生产井数量相同时,CO2注入压力越高,井组CH4产气速度越大。例如,在未关井期间,井组CH4产气速度由大到小对应的注气压力依次为9.5、6.5和3.5 MPa。此外,在序贯关井方式下CO2-ECBM工程的最后一次关井过程中,3.5、6.5和9.5 MPa注气压力下的W1井CH4产气速度分别高于220、390和520 m3/d。

与同时关井方式下的煤储层CH4含气量分布特征相似,序贯关井方式下采用3.5、6.5和9.5 MPa注气压力时的煤储层CH4含气量在CO2-ECBM工程结束时也呈非均质分布,数值范围也随CO2注气压力的增加而扩大(图20)。3.5、6.5和9.5 MPa注气压力下的储层CH4含气量分别为1.13~16.60、1.13~21.90、1.13~25.60 m3/t,平均值分别为8.24、10.02、10.87 m3/t。根据初始和工程结束时煤储层CH4含气量的数值,可以计算出3.5、6.5和9.5 MPa注气压力下储层煤层气采收率分别为41.63%、29.03%和23.01%,即CH4采收率随注气压力增加而降低。

3.3.2 基本指标拟合

图21展示了序贯关井时CO2-ECBM工程时间、CH4产气量、CO2封存量与封存率随注气压力变化情况。随着CO2注气压力的增加,工程时间、CH4产气量逐渐降低,而CO2封存量和封存率逐渐升高。它们之间的关系可以用指数函数进行表征:

$$ \left\{ \begin{gathered} {t_{\text{p}}} = {\text{7 929}}{\text{.850 7}} + {\text{104 209}} \times {\text{0}}{\text{.715 }}{{\text{5}}^{{P_{{\text{in}}}}}} \\ {q_{\text{p}}} = {\text{3}}{\text{.627 7}} \times {10^7} + {\text{1}}{\text{.148 8}} \times {10^8} \times {\text{0}}{\text{.787 }}{{\text{8}}^{{P_{{\rm{in}}}}}} \\ {q_{\text{s}}} = {\text{2}}{\text{.612 0}} \times {10^8} - {\text{2}}{\text{.444 6}} \times {10^8} \times {\text{0}}{\text{.887 }}{{\text{9}}^{{P_{{\text{in}}}}}} \\ {r_{\text{s}}} = {\text{99}}{\text{.764 3}} - {\text{6}}{\text{.828 6}} \times {\text{0}}{\text{.647 }}{{\text{1}}^{{P_{{\text{in}}}}}} \\ \end{gathered} \right. $$ (7) 3.3.3 CO2注气压力优化

基于式(5)和(7)计算了序贯关井情况下4种目标的效果值随CO2注入压力变化情况(图22)。以综合兼顾、省时提效和CO2封存为目标的效果值随CO2注入压力的增加而增加;以CH4增产为目标的效果值随注入压力的增加而持续减小。此外,与同时关井情况相似,序贯关井时以省时提效为目标的工程效果值在6 MPa以下时小于0,说明在序贯关井时采用低压向煤储层注入CO2也不会获得较好的省时提效工程效果。综合兼顾、省时提效、CH4增产和CO2封存对应的最优CO2注入压力均处于注气压力区间的端点,分别为9.5、9.5、3.50和9.5 MPa。综合兼顾、省时提效和CO2封存对应的最优CO2注入压力相同,说明相同的注气压力能够实现不同的CO2-ECBM工程目标。

3.4 CO2注入优化分析

表7展示了采用最优CO2注入压力时2种关井方式下不同CO2-ECBM目标的工程耗时、CH4产气量、CO2封存量和CO2封存率。采用同时关井方式时,工程时间的顺序为CH4增产 > 综合兼顾 > CO2封存 > 省时提效;CH4产气量的顺序为CH4增产 > 综合兼顾 > CO2封存 > 省时提效;CO2封存量的顺序为综合兼顾 > CO2封存 > 省时提效 > CH4增产;CO2封存率顺序为省时提效 > CO2封存 > 综合兼顾 > CH4增产。采用序贯关井方式时,由于综合兼顾、省时提效、CO2封存3种目标的最优CO2注入压力相同,它们的工程时间、CH4产气量、CO2封存量和CO2封存率也相同,分别为12 262 d、4.819 5×107 m3、1.821 9×108 m3和99.66%;而以CH4增产为目标的工程时间、CH4产气量、CO2封存量和封存率分别为40 218 d、8.613 1×107 m3、0.999 6×108 m3和98.28%。2种关井方式下的各项基本指标特征表明:欲在CO2-ECBM工程中节省时间,就无法获得较好的CH4增产效果;欲获得较好的CH4增产效果,需以较长的工程时间和较差的CO2封存效果为代价。此外,在最优CO2注入压力下,相较于各井同时关井,各井序贯关井以较长的工程时间为代价可以获得较高的CH4产气量、CO2封存量和封存率,这表明如果CO2-ECBM工程时间足够长,采用序贯关井方式可以同时获得较好的CH4增产和CO2封存效果。

表 7 最优CO2注入压力下不同工程目标的基本指标Table 7. Basic indexes of different engineering objectives under optimal CO2 injection pressures工程目标 同时关井 序贯关井 综合兼顾 省时提效 CH4增产 CO2封存 综合兼顾 省时提效 CH4增产 CO2封存 工程时间/d 5 370 3 085 14 488 5 194 12 262 12 262 40 218 12 262 CH4产气量/107 m3 4.309 5 3.396 8 6.995 8 4.245 8 4.819 5 4.819 5 8.613 1 4.819 5 CO2封存量/108 m3 0.397 2 0.371 0 0.367 6 0.396 4 1.821 9 1.821 9 0.999 6 1.821 9 CO2封存率/% 97.42 98.33 94.95 97.48 99.66 99.66 98.28 99.66 4. 结 论

(1)利用拆分−重构法在COMSOL Multiphysics内重构了基于Petrel建立的沁水盆地柿庄南CO2-ECBM研究区煤储层三维非均质地质模型;经检验,重构的地质模型与原始地质模型差异非常小,能够有效表征煤储层的三维空间展布和储层CH4含气量、CH4吸附时间、孔隙度、渗透率、弹性模量和泊松比等属性参数的非均质分布特征;经网格划分,煤储层地质模型被划分为8 370个域单元,网格平均质量为0.75。

(2)注气压力对沁水盆地柿庄南3号煤储层CO2-ECBM存在显著影响,CO2-ECBM工程实施15 a后,CO2注入压力越大,CH4增产效果越明显、CO2封存量越大、高CO2含气量和含酸性裂隙水的煤储层范围越大;受生产井CO2产出的影响,CO2封存率随注气压力升高而降低;受煤储层CH4含气量、CO2吸附能力和孔渗非均质性的影响,W7井比W6井的CH4增产效果更好且CO2产出速度更低。

(3) CO2注气压力对生产井组产出气CO2体积分数、CH4产气速度及煤储层CH4采收率影响显著;以省时提效、CH4增产、CO2封存及3者综合兼顾为工程目标的CO2最优注入压力在采用同时关井方式时分别为8.05、3.50、6.35和6.25 MPa,在采用序贯关井方式时分别9.50、9.50、3.50和9.50 MPa;好的CH4增产效果需以较长的工程时间和较差的CO2封存效果为代价;在最优CO2注入压力下,与同时关井相比,序贯关井通过延长工程时间能够获得较好的CH4增产和CO2封存效果。

-

表 1 角点地质模型与重构地质模型参数对比

Table 1 Parameter comparison between corner grid geological model and reconstructed geological model

项目 模型来源 最小值 最大值 平均值 煤储层厚度/m 角点地质模型 4.912 7.304 6.259 重构地质模型 4.911 7.305 6.259 煤储层CH4含气量/(m3·t−1) 角点地质模型 5.927 25.639 14.119 重构地质模型 5.926 25.640 14.118 CH4吸附时间/d 角点地质模型 6.932 62.391 31.353 重构地质模型 6.930 62.391 31.331 孔隙度/% 角点地质模型 3.938 6.252 5.033 重构地质模型 3.937 6.253 5.033 渗透率/10−15 m2 角点地质模型 0.489 1.955 1.020 重构地质模型 0.488 1.956 1.020 弹性模量/GPa 角点地质模型 2.205 3.798 2.804 重构地质模型 2.205 3.799 2.804 泊松比 角点地质模型 0.326 0.384 0.359 重构地质模型 0.326 0.384 0.359 关键参数 数值 关键参数 数值 初始温度/K 298.15 孔径分布指数 1.00 初始H+浓度/(mmol·L−1) 4.57×10−6 煤岩密度/(kg·m−3) 1450 初始${\rm{HCO}}_3^- $浓度/(mmol·L−1) 5.76 水的密度/(kg·m−3) 1000 初始${\rm{CO}}_3^{2-} $浓度/(mmol·L−1) 1.40×10−2 有效应力系数 0.50 初始OH−浓度/(mmol·L−1) 2.19×10−3 CH4导热系数/(W·(m·K)−1) 3.01×10−2 初始Ca2+浓度/(mmol·L−1) 0.32 CO2导热系数/(W·(m·K)−1) 1.37×10−2 CH4兰氏压力/MPa 2.15 水导热系数/(W·(m·K)−1) 5.99×10−2 CO2兰氏压力/MPa 1.40 煤岩导热系数/(W·(m·K)−1) 0.19 压力系数/MPa−1 7.1×10−2 CH4比热容/(kJ·(kg·K)−1) 2.22 温度系数/K−1 2.10×10−2 CO2比热容/(kJ·(kg·K)−1) 0.84 CH4动力黏度/(Pa·s) 1.34×10−5 水比热容/(kJ·(kg·K)−1) 4.19 CO2动力黏度/(Pa·s) 1.84×10−5 煤比热容/(kJ·(kg·K)−1) 1.35 水动力黏度/(Pa·s) 1.01×10−5 CH4吸附热/(kJ·mol−1) 16.40 CH4指数常数 −15.07 CO2吸附热/(kJ·mol−1) 19.20 CO2指数常数 −12.46 CH4溶解热/(kJ·mol−1) 14.12 CH4温度常数/K 1 545.00 CO2溶解热/(kJ·mol−1) 19.99 CO2温度常数/K 2 258.50 残余水饱和度 0.05 标准温度/K 273.15 残余气饱和度 0 标准压力/MPa 1.01×10−2 方解石中性活化能/(kJ·mol−1) 23.50 CH4扩散活化能/(kJ·mol−1) 34.00 方解石酸性活化能/(kJ·mol−1) 14.40 CO2扩散活化能/(kJ·mol−1) 18.00 中性反应速率常数/(mol·(m2·s)−1) 1.55×10−6 摩尔气体常数/(J·(mol·L)−1) 8.31 酸性反应速率常数/(mol·(m2·s)−1) 0.50 气体滑脱系数/MPa 0.75 方解石比表面积/(m2·kg−1) 9.8×10−3 排驱压力/MPa 1.00×10−2 方解石密度/(kg·m−3) 2710 表 3 数值模拟方案

Table 3 Scheme for numerical simulation

模拟阶段 排采压力/MPa 注入井 CO2注入压力/MPa CO2注入温度/℃ 模拟时长/a 生产历史拟合 实测 — — — 实测 CO2-ECBM模拟 0.1 W3 5.5、6.5、7.5、8.5、9.5 20 15 表 4 不同注入压力下井组CH4增产情况

Table 4 CH4 stimulation of well group under different injection pressures

CO2注入压力/MPa 5.5 6.5 7.5 8.5 9.5 CH4增产量/106 m3 1.11 1.52 2.00 2.57 3.23 CH4增产率/% 4.93 6.76 8.93 11.46 14.39 表 5 煤储层CO2注入与封存情况

Table 5 CO2 injection and storage of coal reservoir

注入压力/MPa 累计注入量/m3 累计产出量/m3 封存量

/m3封存率/% 5.5 32 853 745 745 129 32 108 616 97.73 6.5 44 035 152 1 208 946 42 826 206 97.25 7.5 56 801 441 1 863 003 54 938 437 96.72 8.5 71 155 914 2 757 821 68 398 093 96.12 9.5 87 100 860 3 953 589 83 147 271 95.46 表 6 目标函数权重系数

Table 6 Weight coefficient of objective function

工程目标 β1 β2 β3 综合兼顾 1/3 1/3 1/3 省时提效 3/5 1/5 1/5 CH4增产 1/5 3/5 1/5 CO2封存 1/5 1/5 3/5 表 7 最优CO2注入压力下不同工程目标的基本指标

Table 7 Basic indexes of different engineering objectives under optimal CO2 injection pressures

工程目标 同时关井 序贯关井 综合兼顾 省时提效 CH4增产 CO2封存 综合兼顾 省时提效 CH4增产 CO2封存 工程时间/d 5 370 3 085 14 488 5 194 12 262 12 262 40 218 12 262 CH4产气量/107 m3 4.309 5 3.396 8 6.995 8 4.245 8 4.819 5 4.819 5 8.613 1 4.819 5 CO2封存量/108 m3 0.397 2 0.371 0 0.367 6 0.396 4 1.821 9 1.821 9 0.999 6 1.821 9 CO2封存率/% 97.42 98.33 94.95 97.48 99.66 99.66 98.28 99.66 -

[1] 张守仁,桑树勋,吴见,等. CO2驱煤层气关键技术研发及应用[J]. 煤炭学报,2022,47(11):3952−3964. ZHANG Shouren, SANG Shuxun, WU Jian, et al. Progress and application of key technologies for CO2 enhancing coalbed methane[J]. Journal of China Coal Society,2022,47(11):3952−3964.

[2] PAN Z J, YE J P, ZHOU F B, et al. CO2 storage in coal to enhance coalbed methane recovery: A review of field experiments in China[J]. International Geology Review,2018,60(5−6):754−776. doi: 10.1080/00206814.2017.1373607

[3] ASIF M, WANG L, PANIGRAHI D C, et al. Integrated assessment of CO2-ECBM potential in Jharia Coalfield, India[J]. Scientific Reports,2022,12:7533. doi: 10.1038/s41598-022-10574-5

[4] YAMAZAKI T, ASO K, CHINJU J. Japanese potential of CO2 sequestration in coal seams[J]. Applied Energy,2006,83(9):911−920. doi: 10.1016/j.apenergy.2005.11.001

[5] YAMAGUCHI S, OHGA K, FUJIOKA M, et al. Field test and history matching of the CO2 sequestration project in coal seams in Japan[J]. International Journal of the Society of Materials Engineering for Resources,2006,13(2):64−69. doi: 10.5188/ijsmer.13.64

[6] 蔡颖,申建,李超,等. 多重地质属性约束下CO2-ECBM选址原则及实例[J]. 煤炭学报,2020,45(12):4111−4120. CAI Ying, SHEN Jian, LI Chao, et al. Principles and examples of CO2-ECBM site selection under the constraints of multiple geological attributes[J]. Journal of China Coal Society,2020,45(12):4111−4120.

[7] 凡永鹏,霍中刚,王永. 基于流−固−热耦合的CO2-ECBM数值模拟研究[J]. 煤矿安全,2022,53(2):162−169. FAN Yongpeng, HUO Zhonggang, WANG Yong. Numerical simulation of CO2-ECBM based on fluid-solid thermal coupled model[J]. Safety in Coal Mines,2022,53(2):162−169.

[8] 刘世奇,方辉煌,桑树勋,等. 基于多物理场耦合求解的煤层CO2-ECBM数值模拟研究[J]. 煤炭科学技术,2019,47(9):51−59. LIU Shiqi, FANG Huihuang, SANG Shuxun, et al. Numerical simulation study on coal seam CO2-ECBM based on multi-physics fields coupling solution[J]. Coal Science and Technology,2019,47(9):51−59.

[9] 张松航,唐书恒,万毅,等. 晋城无烟煤煤中CH4和CO2运移规律研究[J]. 中国矿业大学学报,2012,41(5):770−775. ZHANG Songhang, TANG Shuheng, WAN Yi, et al. The migration of CH4 and CO2 in Jincheng anthracite coal[J]. Journal of China University of Mining & Technology,2012,41(5):770−775.

[10] 陈军斌,熊鹏辉,索根喜,等. 吸附性气体对煤岩基质变形和渗透率的影响[J]. 大庆石油地质与开发,2021,40(1):146−153. doi: 10.19597/j.issn.1000-3754.201910007 CHEN Junbin, XIONG Penghui, SUO Genxi, et al. Effects of the adsorbed gas on the deformation and permeability of the coal matrix[J]. Petroleum Geology & Oilfield Development in Daqing,2021,40(1):146−153. doi: 10.19597/j.issn.1000-3754.201910007

[11] ZHANG B, YE J, LI Y, et al. Simulation of key parameters in CO2 injection for enhanced coalbed methane recovery in a deep well group[J]. Energy Sources, Part A. Recovery, Utilization, and Environmental Effects,2018,40(18):2219−2226. doi: 10.1080/15567036.2018.1496193

[12] FAN C, ELSWORTH D, LI S, et al. Thermo-hydro-mechanical-chemical couplings controlling CH4 production and CO2 sequestration in enhanced coalbed methane recovery[J]. Energy,2019,173:1054−1077. doi: 10.1016/j.energy.2019.02.126

[13] LIU S, FANG H, Sang S, et al. CO2 injectability and CH4 recovery of the engineering test in qinshui Basin, China based on numerical simulation[J]. International Journal of Greenhouse Gas Control,2020,95(4):102980.

[14] SAMS W N, BROMHAL G, JIKICH S, et al. Field-project designs for carbon dioxide sequestration and enhanced coalbed methane production[J]. Energy & Fuels,2007,19(6):2287−2297.

[15] PERERA M S A, RANJITH P G, RANATHUNGA A S, et al. Optimization of enhanced coal-bed methane recovery using numerical simulation[J]. Journal of Geophysics and Engineering,2015,12(1):90−107. doi: 10.1088/1742-2132/12/1/90

[16] THANH H V, LEE K K. 3D geo-cellular modeling for Oligocene reservoirs: A marginal field in offshore Vietnam[J]. Journal of Petroleum Exploration and Production Technology,2022,12:1−19. doi: 10.1007/s13202-021-01300-4

[17] YESTE L M, PALOMINO R, VARELA A N, et al. Integrating outcrop and subsurface data to improve the predictability of geobodies distribution using a 3D training image: A case study of a Triassic Channel-Crevasse-splay complex[J]. Marine and Petroleum Geology,2021,129:105081. doi: 10.1016/j.marpetgeo.2021.105081

[18] 张亮,姚磊华,王迎东. 基于COMSOL Multiphysics的三维地质建模方法[J]. 煤田地质与勘探,2014,42(6):14−19. doi: 10.3969/j.issn.1001-1986.2014.06.003 ZHANG Liang, YAO Leihua, WANG Yingdong. 3D geological modeling method based on COMSOL Multiphysics[J]. Coal Geology & Exploration,2014,42(6):14−19. doi: 10.3969/j.issn.1001-1986.2014.06.003

[19] LI S, FAN C, HAN J, et al. A fully coupled thermal-hydraulic-mechanical model with two-phase flow for coalbed methane extraction[J]. Journal of Natural Gas Science and Engineering,2016,33:324−336. doi: 10.1016/j.jngse.2016.05.032

[20] FAN Z, FAN G, ZHANG D, et al. Optimal injection timing and gas mixture proportion for enhancing coalbed methane recovery[J]. Energy,2021,222:119880. doi: 10.1016/j.energy.2021.119880

[21] MA T, RUTQVIST J, OLDENBURG CM, et al. Coupled thermal-hydrological-mechanical modeling of CO2-enhanced coalbed methane recovery[J]. International Journal of Coal Geology,2017,179:81−91. doi: 10.1016/j.coal.2017.05.013

[22] FAN Y, DENG C, ZHANG X, et al. Numerical study of CO2-enhanced coalbed methane recovery[J]. International Journal of Greenhouse Gas Control, 2018, 76: 12−23.

[23] FANG H, SANG S, LIU S. The coupling mechanism of the thermal-hydraulic-mechanical fields in CH4-bearing coal and its application in the CO2-enhanced coalbed methane recovery[J]. Journal of Petroleum Science and Engineering,2019,181:106177. doi: 10.1016/j.petrol.2019.06.041

[24] LIU X, SANG S, ZHOU X, et al. Coupled adsorption-hydro-thermo-mechanical-chemical modeling for CO2 sequestration and well production during CO2-ECBM[J]. Energy,2023,262:125306. doi: 10.1016/j.energy.2022.125306

[25] ZHOU F, HUSSAIN F, CINAR Y. Injecting pure N2 and CO2 to coal for enhanced coalbed methane: Experimental observations and numerical simulation[J]. International Journal of Coal Geology,2013,116−117:53−62. doi: 10.1016/j.coal.2013.06.004

[26] ZHANG C, WANG E, LI B, et al. Laboratory experiments of CO2-enhanced coalbed methane recovery considering CO2 sequestration in a coal seam[J]. Energy,2023,262:125473. doi: 10.1016/j.energy.2022.125473

[27] 杨寒雨,赵晓永,王磊. 数据归一化方法综述[J]. 计算机工程与应用,2023,59(3):13−22. doi: 10.3778/j.issn.1002-8331.2207-0179 YANG Hanyu, ZHAO Xiaoyong, WANG Lei. Review of data normalization methods[J]. Computer Engineering and Applications,2023,59(3):13−22. doi: 10.3778/j.issn.1002-8331.2207-0179

[28] ZHANG T, ZHANG W, YANG R, et al. CO2 injection deformation monitoring based on UAV and InSAR technology: A case study of Shizhuang Town, Shanxi Province, China[J]. Remote Sensing,2022,14:237. doi: 10.3390/rs14010237

-

期刊类型引用(5)

1. 薛恩思. CO_2-ECBM过程中煤层渗透率演化规律. 煤矿安全. 2024(04): 42-47 .  百度学术

百度学术

2. 段海强. 粘土中钻孔灌注桩墙体支护开挖弯矩数值模拟研究. 建筑技术. 2024(16): 2030-2033 .  百度学术

百度学术

3. 韩文彬,张迪,郑义,刘东洋. 煤层裂隙粗糙度与瓦斯开采效率耦合数值模型. 煤矿安全. 2024(08): 51-61 .  百度学术

百度学术

4. 张迪,丰程涛,李鹏,田昊晨. 煤粒瓦斯解吸-扩散数值模型适用性及参数敏感性研究. 煤炭工程. 2024(10): 281-288 .  百度学术

百度学术

5. 李远铎 ,丁帅伟 ,张蒙 ,许川 ,樊纹宇 ,屈传超 . 考虑封存机理的低渗透油藏CO_2驱油与封存注采参数敏感性分析. 新疆石油地质. 2024(06): 711-718 .  百度学术

百度学术

其他类型引用(3)

下载:

下载: